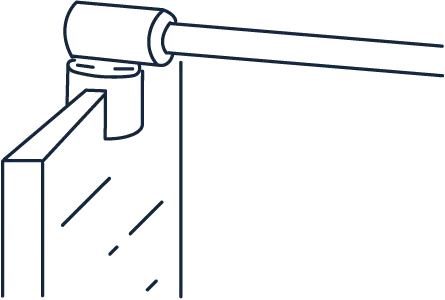

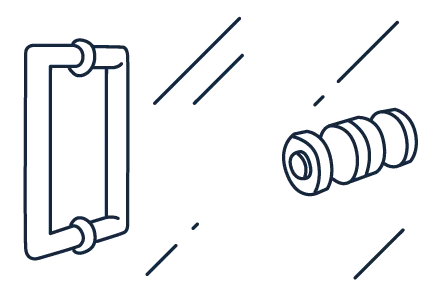

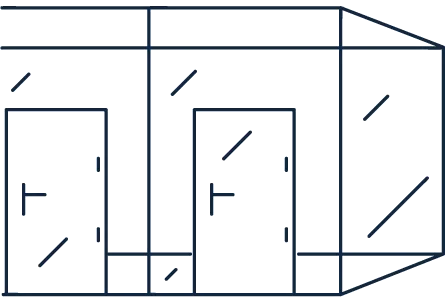

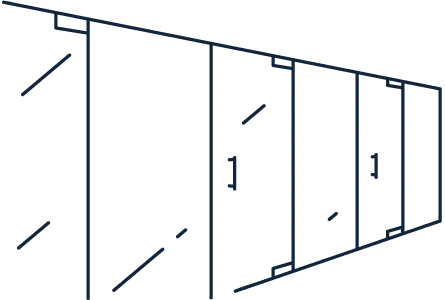

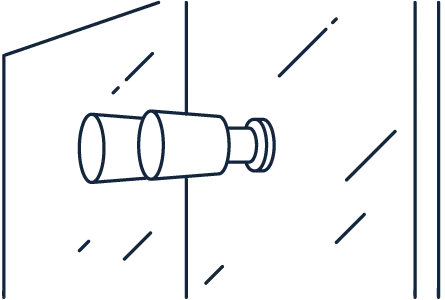

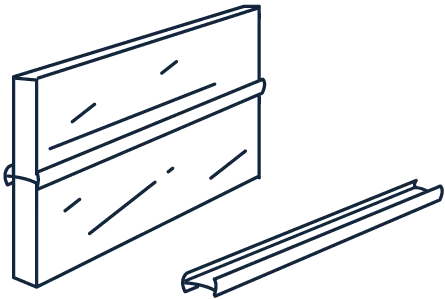

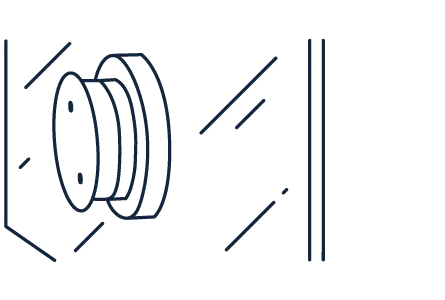

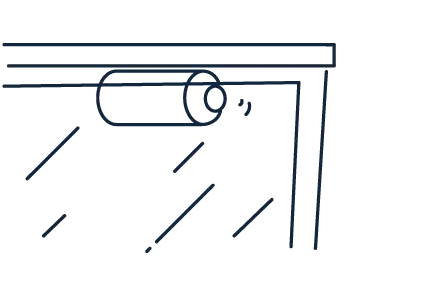

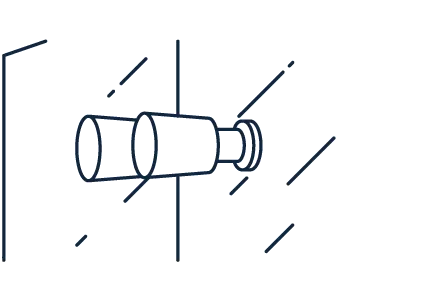

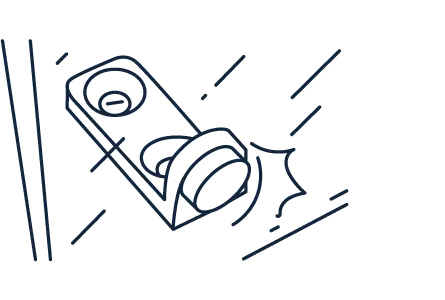

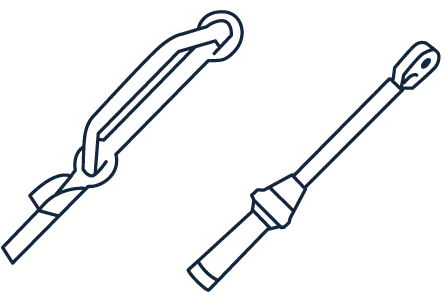

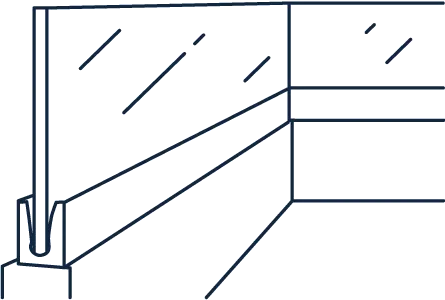

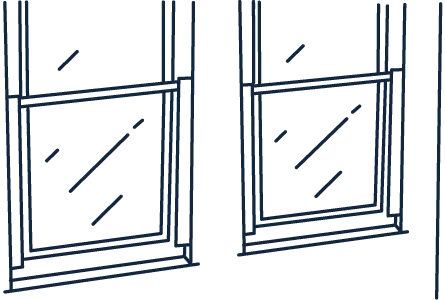

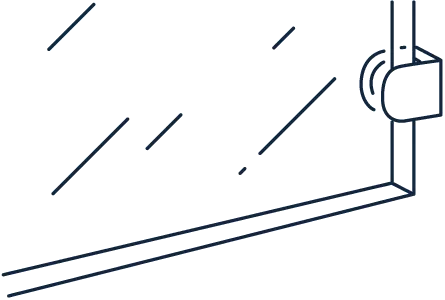

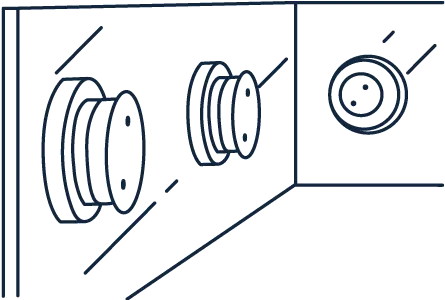

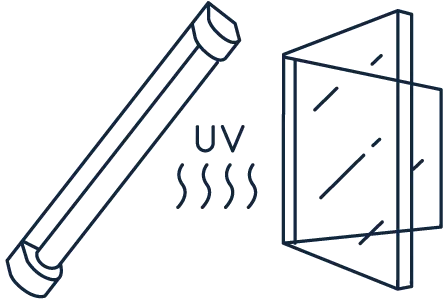

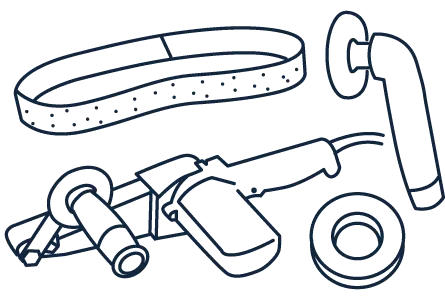

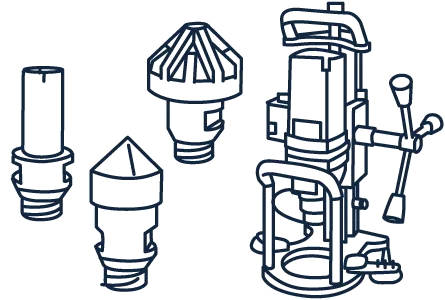

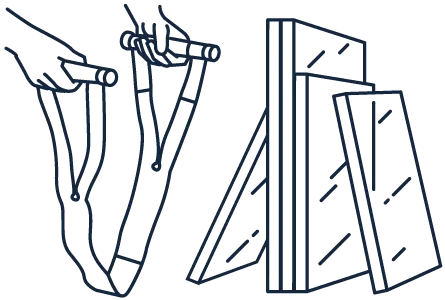

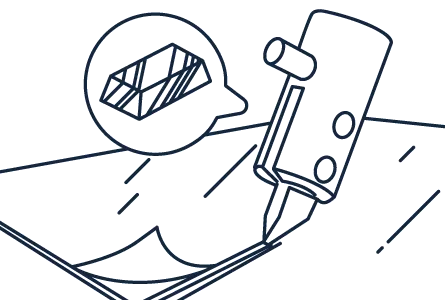

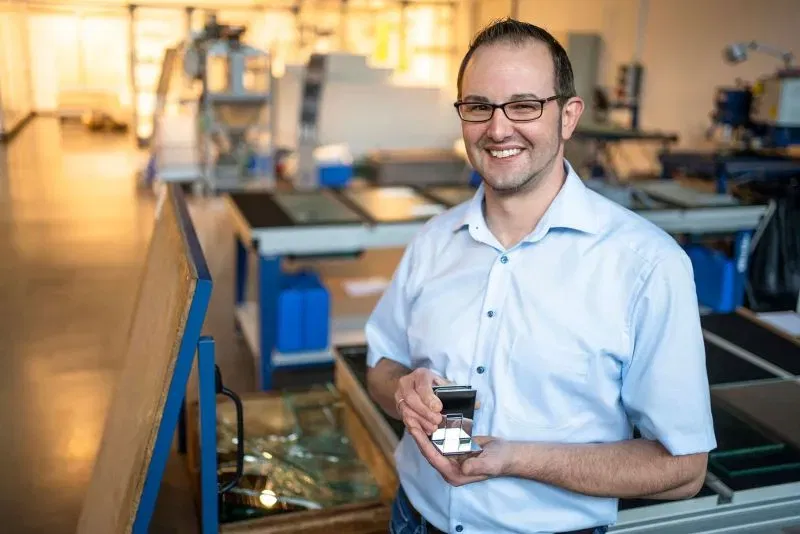

Glass fittings

Glass fittings

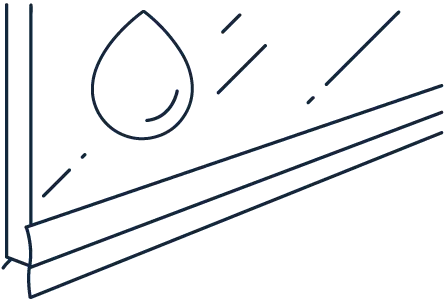

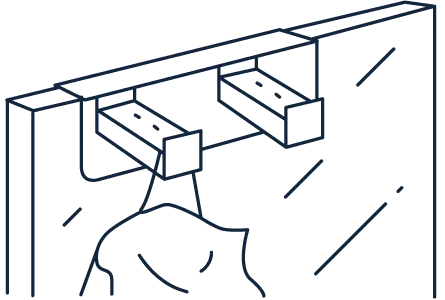

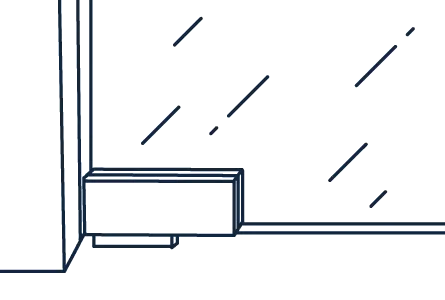

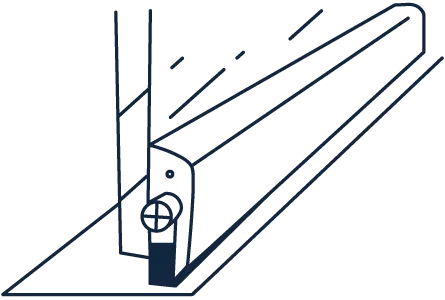

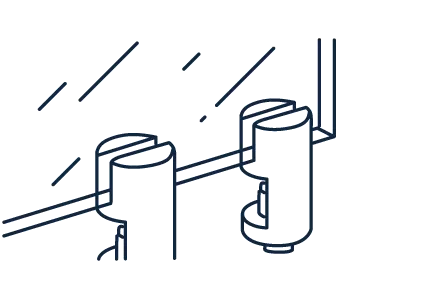

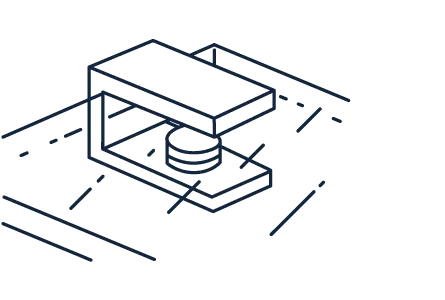

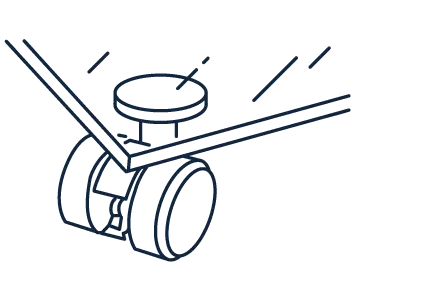

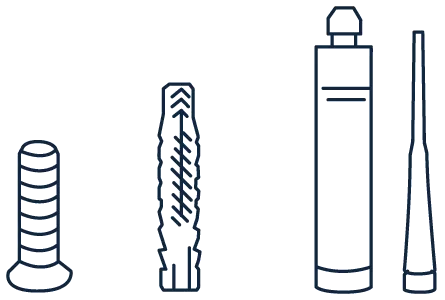

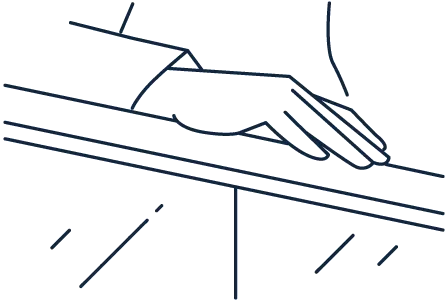

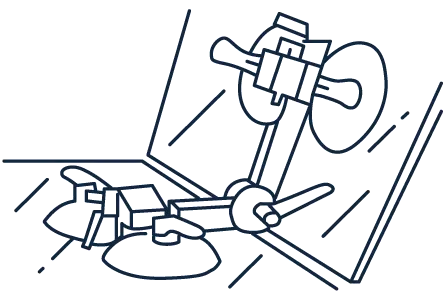

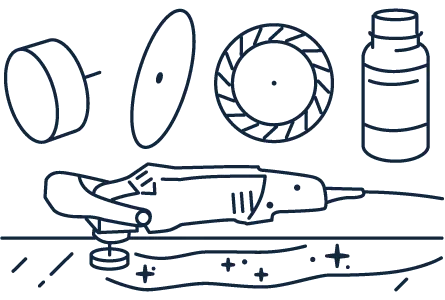

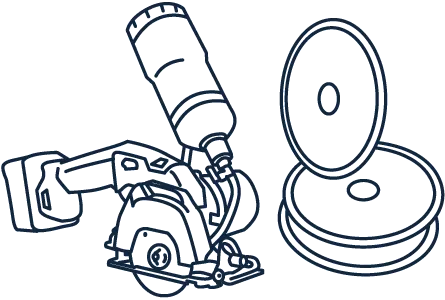

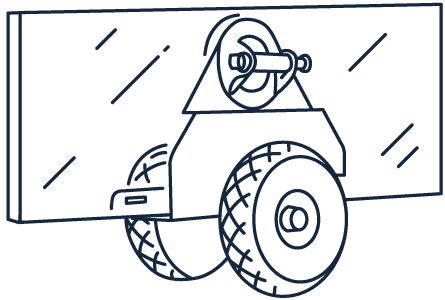

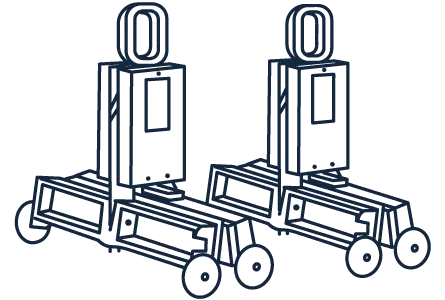

Workshop supplies

Workshop supplies