It's the wheel that counts

Best raw materials and perfect processing

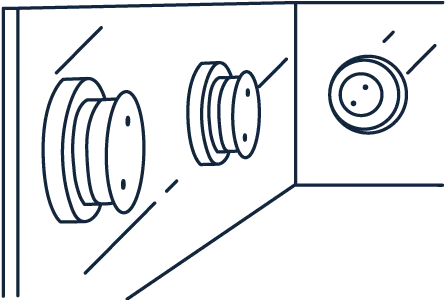

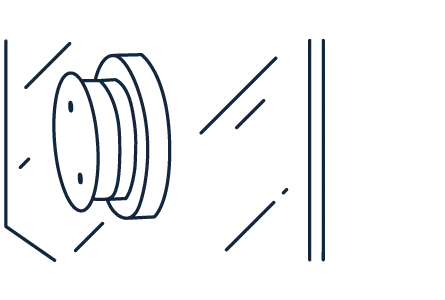

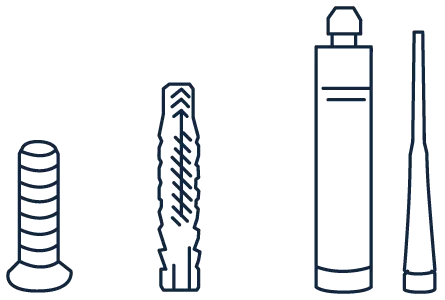

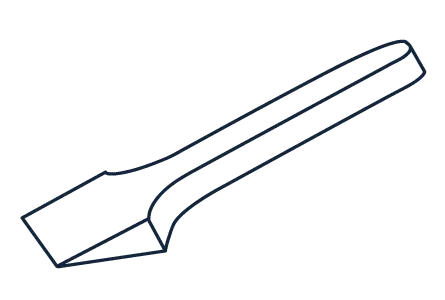

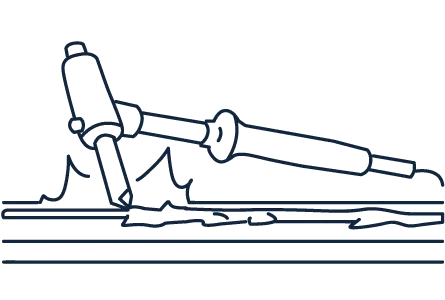

Bohle recognised the extraordinary properties of tungsten carbide early on. A multiple running performance compared to conventional steel wheels is one of the great advantages of the material. Furthermore, tungsten carbide cutting wheels are characterised by uniformly good cutting properties, and the resulting clean breaking edges for different glass thicknesses. A similar development is taking place with PCD (polycrystalline diamond), which is used in particular when exceptionally long tool lives are also required. A careful selection and analysis of the raw material is the starting point for the production of high-quality cutting wheels.

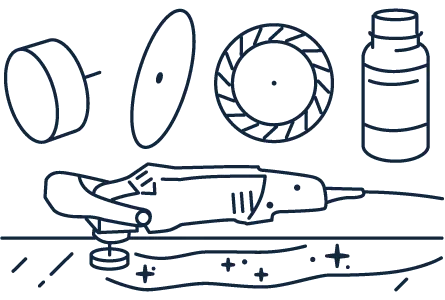

But not only the basic material is decisive for the quality. The greatest know-how lies in the further processing of the blanks, which are given their very special finish on our self-developed machines. Because only the grind, the execution of which depends on the later application, leads to a uniformly long service life and optimal cutting results. The best running properties of Silberschnitt® cutting wheels are achieved by machining the bores in the honing process as well as the finest grinding and lapping of the side surfaces. The majority of well-known cutting machine manufacturers worldwide trust in Silberschnitt® quality and equip their systems with industrial cutting technology from Bohle as standard.

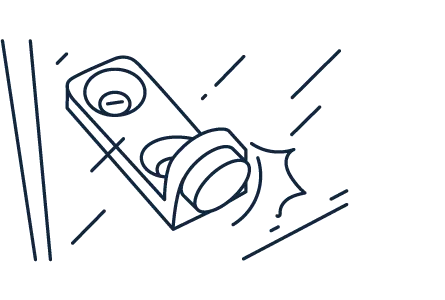

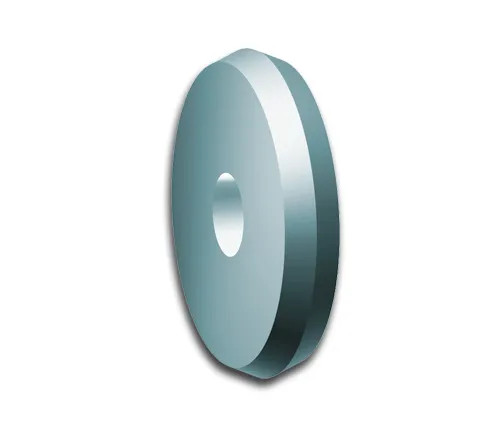

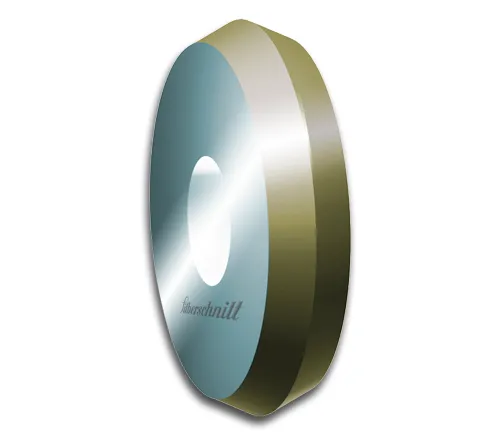

Cutmaster® Gold - The Long life Cutting Wheel

The innovative Cutmaster® Gold carbide cutting wheel achieves what the glass processing industry has long been waiting for: the balancing act between cost reduction and simultaneous quality improvement. Cutmaster® Gold enables tool life that far exceeds that of a conventional carbide cutting wheel. In addition to the pure cost savings, the increased tool life also means a reduction in maintenance and set-up cycles, as cutting wheels and wheel holders need to be replaced less frequently.

Another advantage is the improved cut quality, which remains consistently at the highest level throughout the entire service life, which significantly reduces the risk of glass breakage and ensures process stability.

Unique performance

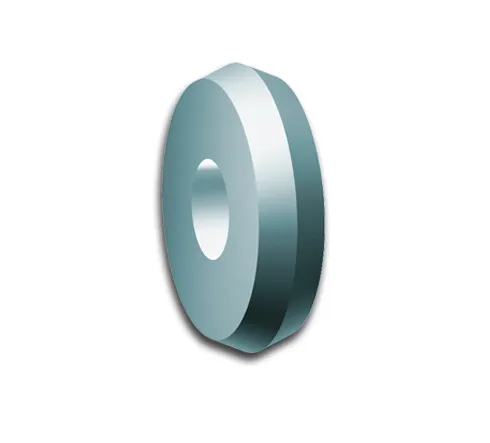

Cutmaster ® Platinum - The cutting wheel for the highest demands

Wide range of applications

- Float glass

- Solar glass

- Optical filters

- Quartz glass