Ramsgate Glass invests in glass processing to meet demand for home improvements

10.10.2021

We talk to Kevin Cox, Director of Ramsgate Glass, about how the company has been able to take advantage of increasing demand for high end home improvements through its investment in glass processing and a 35-year working relationship with Bohle.

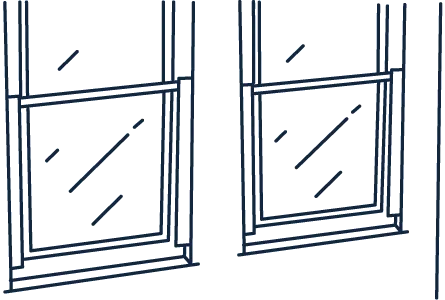

“We’ve noticed a big uplift in demand over the last 18 months,” says Kevin Cox, Director Ramsgate Glass. “That’s a direct result of Covid and lockdown. A lot of people that would have normally enjoyed a foreign holiday have not been able to do so, and they’ve used the money that they’ve saved to improve their homes instead. That’s included refurbishing old bathrooms to include more stylish, frameless showers and upgrading kitchens with glass splashbacks. We’ve also seen a big increase in demand for balustrades – for balconies and for staircases,” he adds. “Our turnover has increased by around 25% and we’re confident that we’re going to maintain a similar output for another 12 months at least.”

Family business

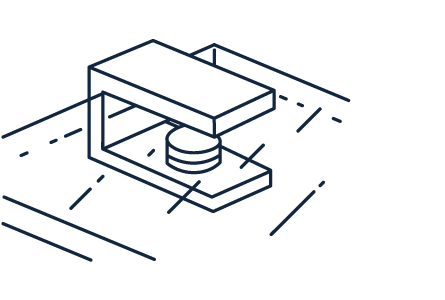

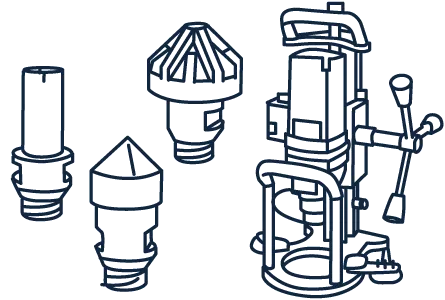

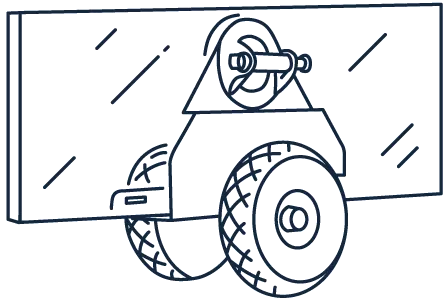

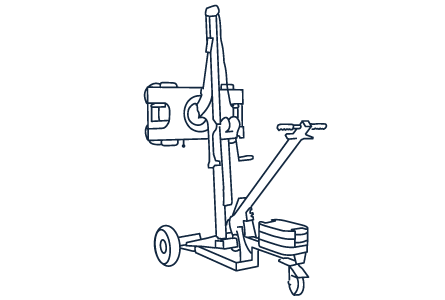

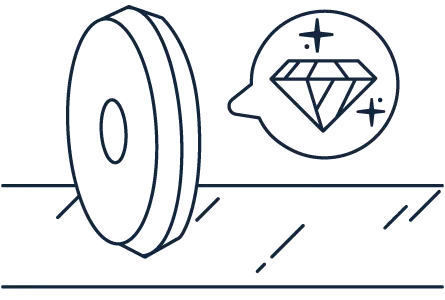

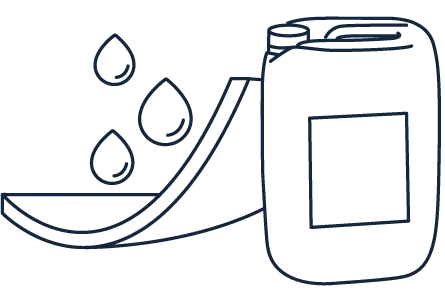

Sedimentor

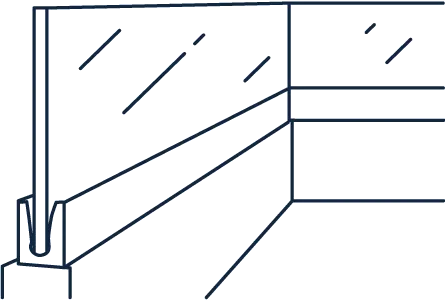

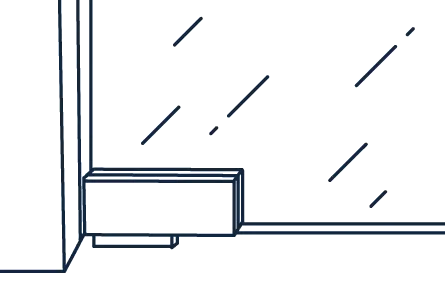

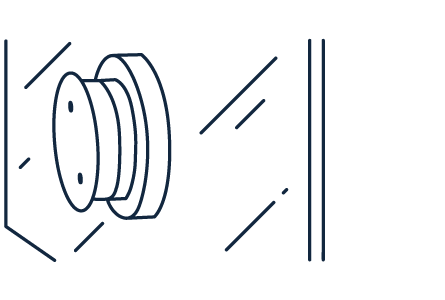

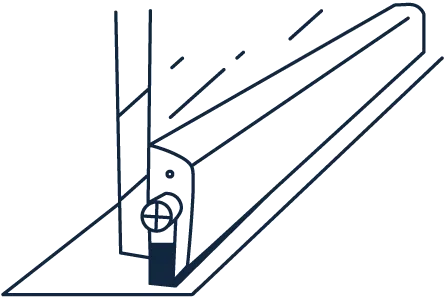

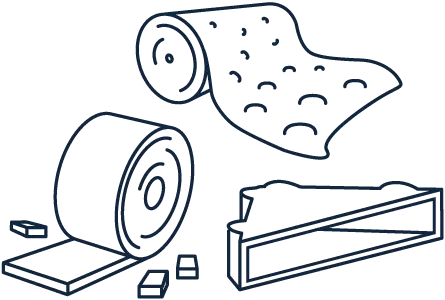

Available in three different sizes, with a filling quantity of 2,100 litres, 1,000-litres and 320 litres, Bohle’s Sedimentor is suitable for elementary to chain-linked, double-sided straight line edgers. Using a high tech multi-stage process, Sedimentors pump water into a settling tank, removing around 70% of heavier glass particles from coolant, before a powdered flocculant is added which then bonds to any remaining glass particles to make them sink. This sludge is then flushed out into a filter bag, leaving behind cleaned cooling water that can be returned to the cooling circuit. Designed to reduce wear and tear on glass cutting machinery, improving performance and reducing downtime in the process, Bohle estimates that by introducing a Sedimentor, glass processors can improve the performance of their machinery by as much as 20% and the service life of tools by up 30%.

Home improvement

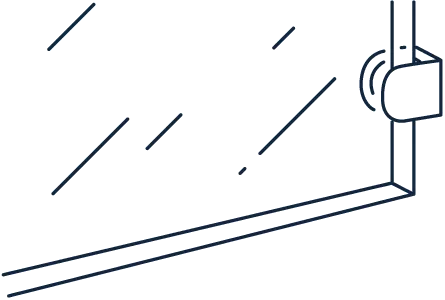

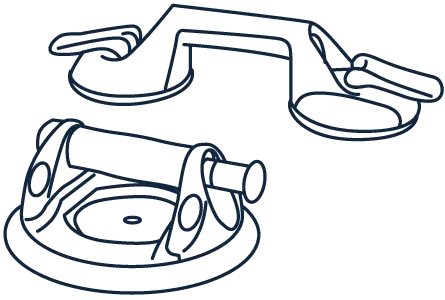

“Our ability to process glass in-house has really enabled us to make the most of the home improvement boom and it’s opened up big opportunities in the commercial market as well – but our biggest challenge now is in getting hold of enough stock,” says Kevin. “Glass supply has affected everyone, we know that we’re in the same boat, but even sourcing from three different suppliers is proving to be problematic. Prices have increased – as much as 50% on oversized laminates – so it’s important that we operate as efficiently as possible. "Working with Bohle, we can do just that. We see Paul [Miller, Bohle Sales Director] at least once or twice a month,” he continues. “The level of support we have is invaluable, as is the quality of Bohle’s products. At the premium end of the

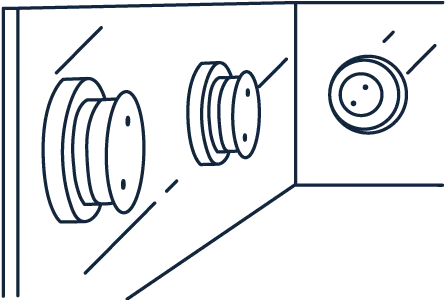

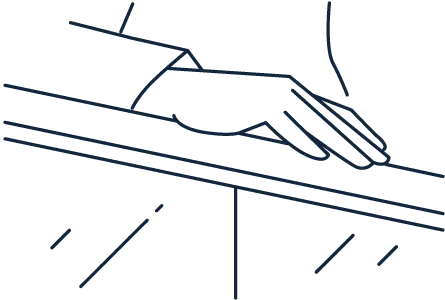

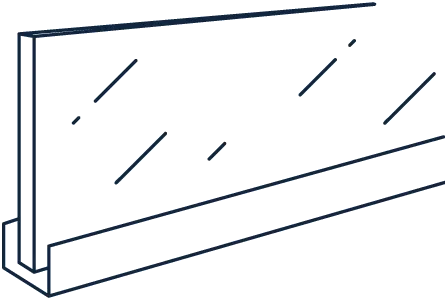

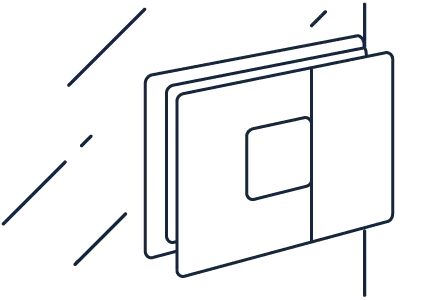

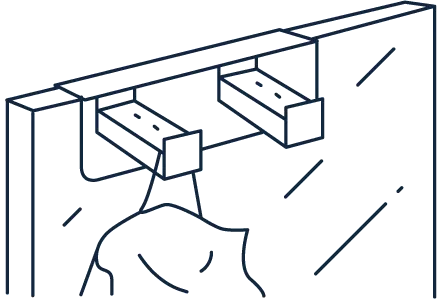

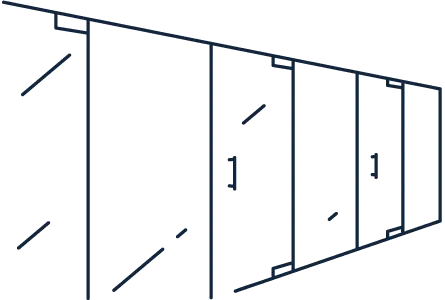

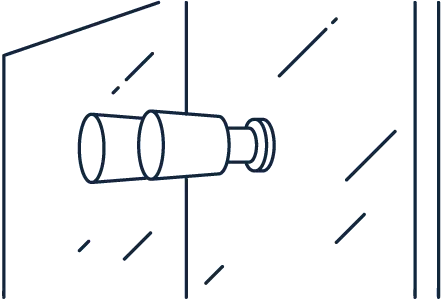

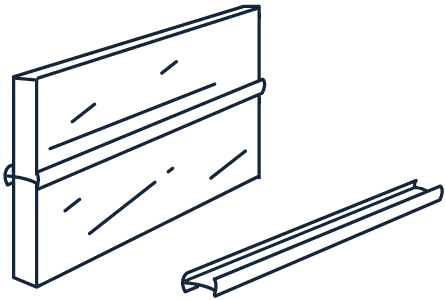

home improvement market, cheap product is a false economy – we’ve tried using inferior clamps for balustrades in the past and they’ve failed before we’ve even finished the installation! Bohle’s MasterTrack ST shower and VetroMount balustrade systems on the other hand are extremely well designed, the quality is faultless – we can trust them to perform. “Looking ahead, there’s no sign of demand slowing down,” Kevin concludes. “There’s still going to be a limit on the amount of people taking holidays overseas even in 2022, it’s going to be a similar situation to the one we have now. “But with the investment we have made in our glass processing facility and with the product and experience we have at our disposal, we’re in a strong position to make the most of it!”

For more about Bohle’s product and service offer, visit www.bohle.com, email info@bohle.ltd.uk or call the customer services team free on 0800 616151 for more information.