Muscles for mirrors

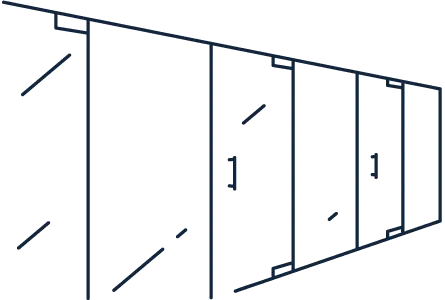

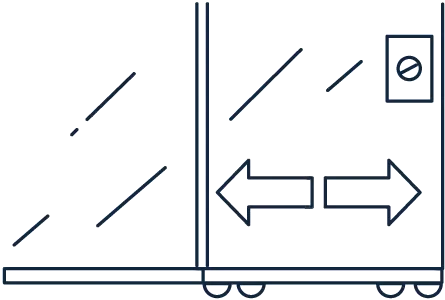

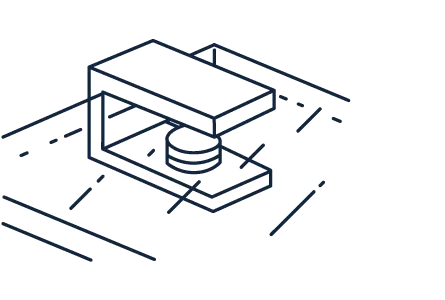

Hanging mirrors with mirror plates

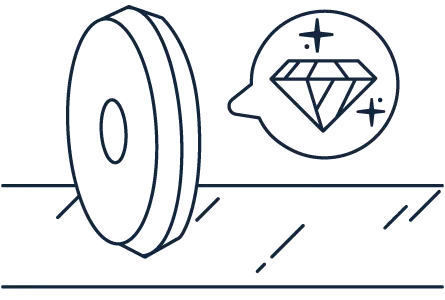

2 important factors: size and load capacity

- A 70 x 70 mm mirror plate holds 3 kg

- A 100 x 100 mm mirror plate holds 6 kg

- A 100 x 200 mm mirror plate holds 12 kg

- A 100 x 300 mm mirror plate holds 18 kg

The benefits of mirror plates

- Demountable Suitable for bathrooms or wet rooms

- Odourless

- High ageing and temperature resistance

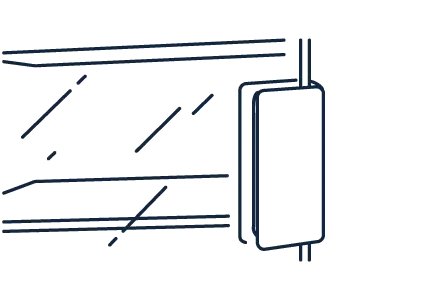

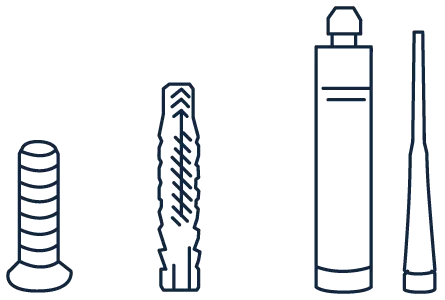

The golden rule of mirror plates: 10 - 30 - 10

To the shop

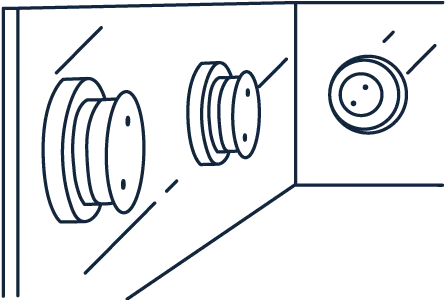

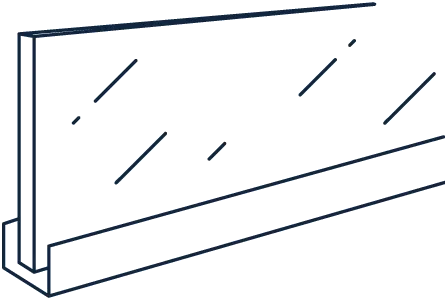

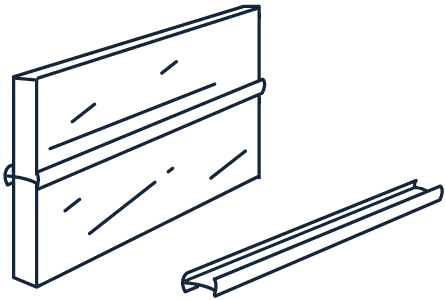

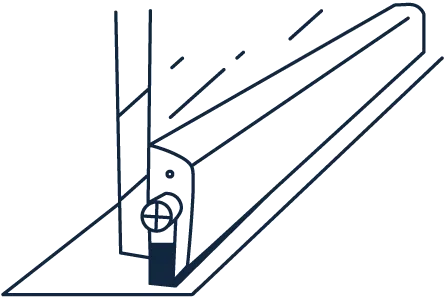

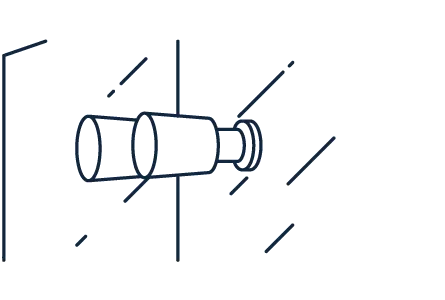

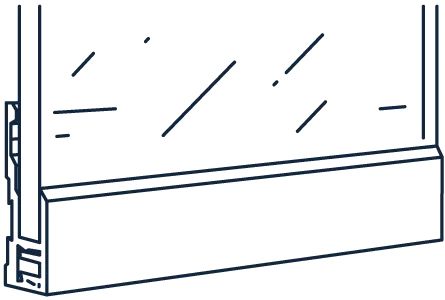

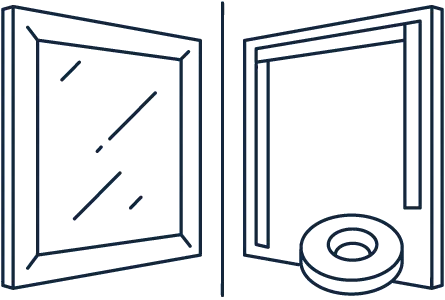

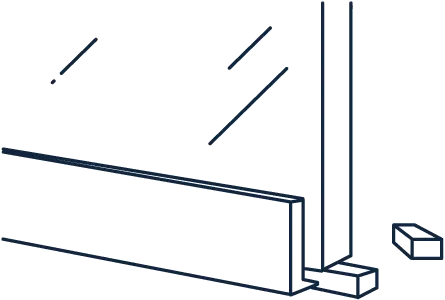

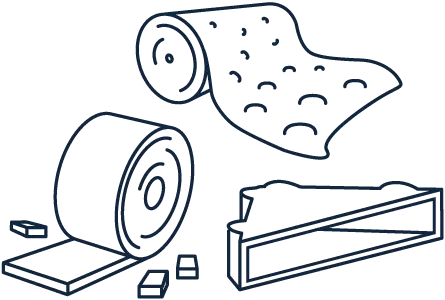

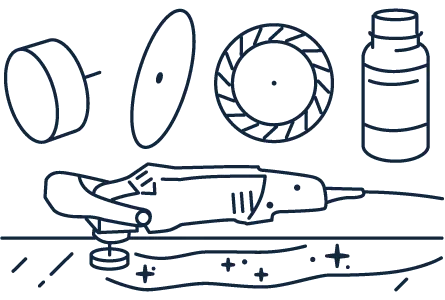

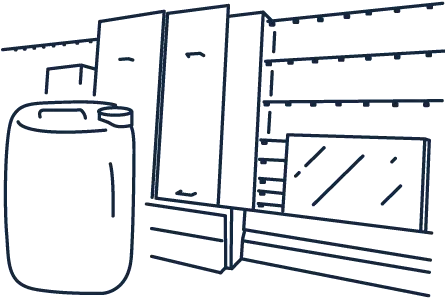

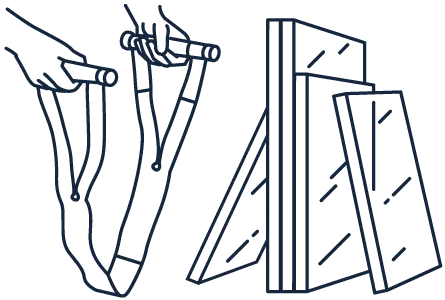

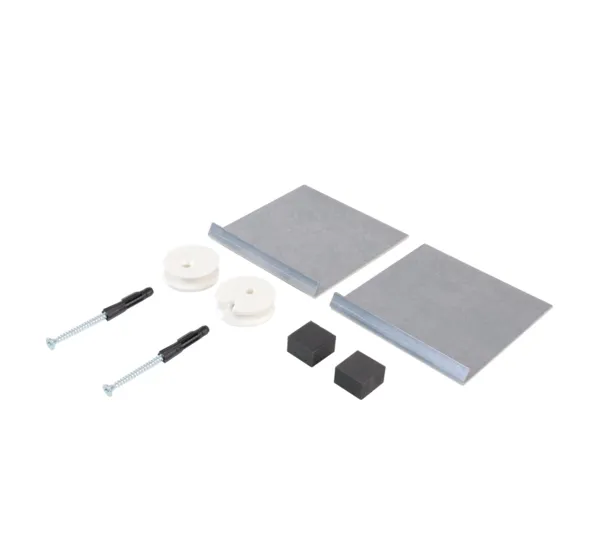

Mirror plates are available in many shapes and varieties. They are available individually or as a set with accessories such as eccentric discs, spacers, magnets or press studs. Mirror plates are either fitted with eyelets or bevelled edges to make it easy to hang the mirror on the wall.

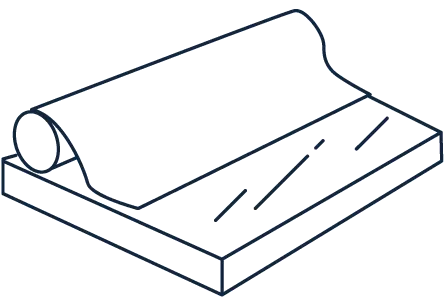

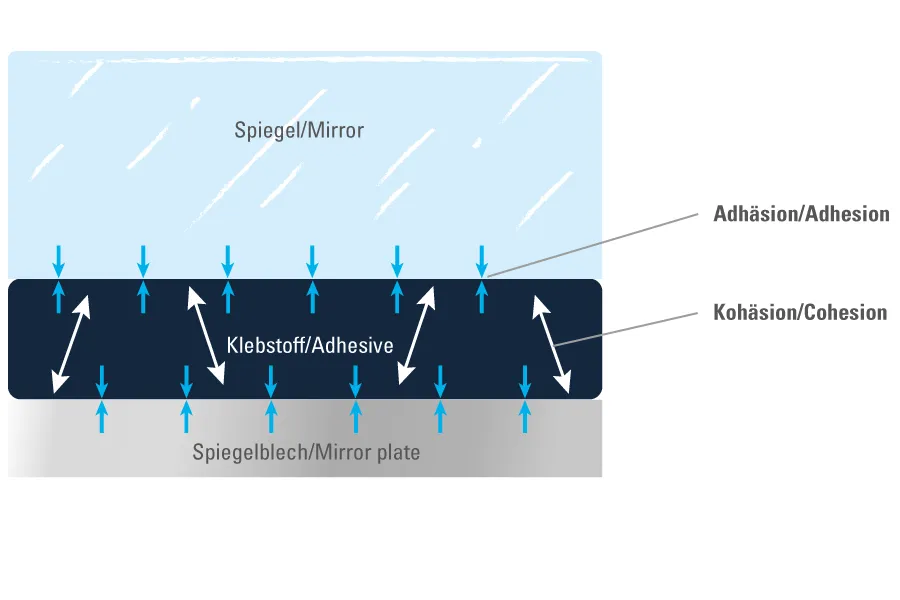

How do mirror sheets stay on the wall?

FAQ

What are self-adhesive bonding sheets suitable for?

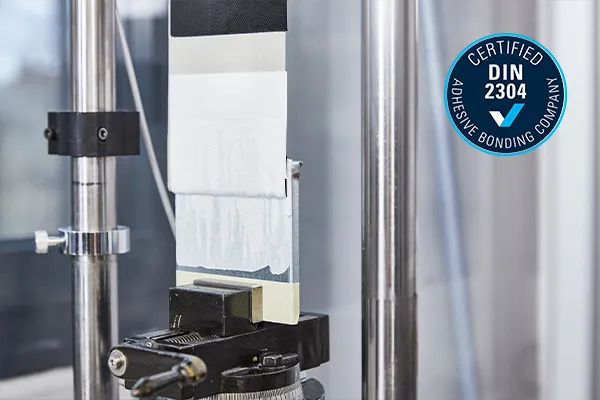

Bohle mirror plates have been extensively tested for the attachment of mirrors in accordance with DIN 1036. Any other application must be tested separately.

Bohle mirror plates have been extensively tested for the attachment of mirrors in accordance with DIN 1036. Any other application must be tested separately.

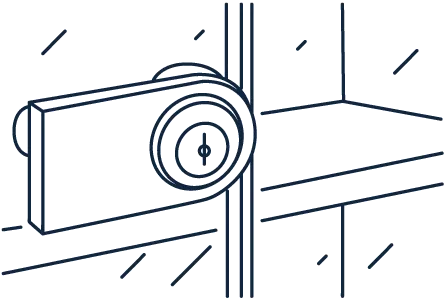

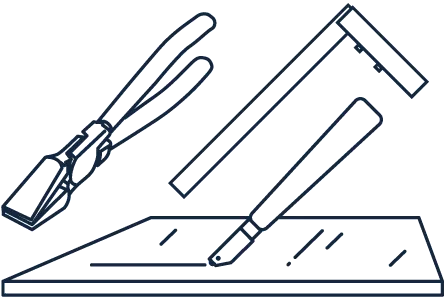

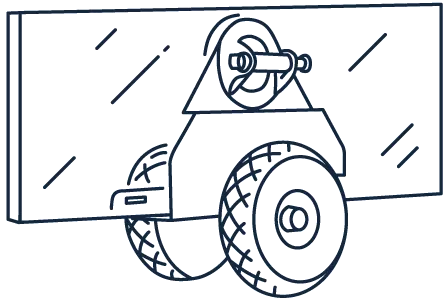

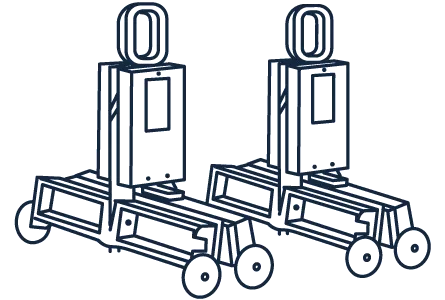

How do I hang a mirror with mirror plates?

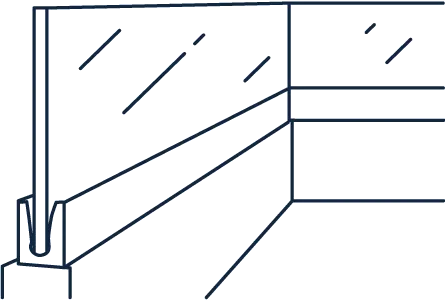

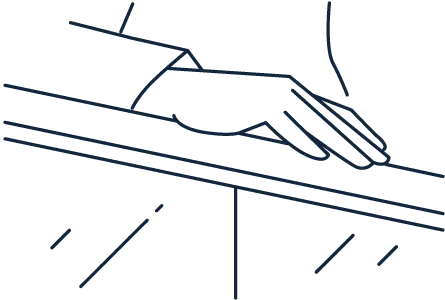

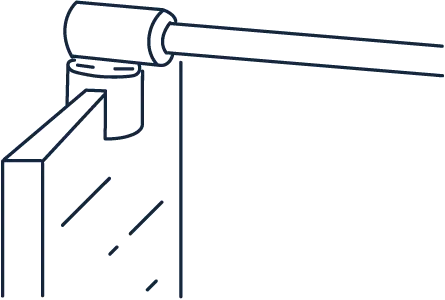

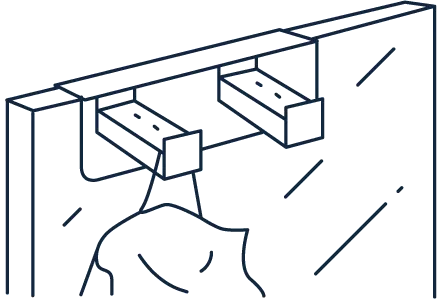

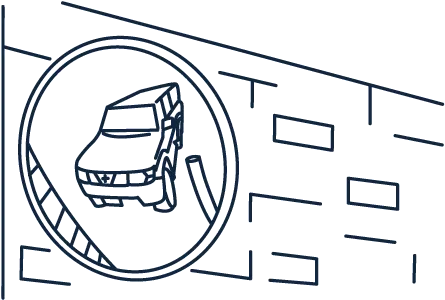

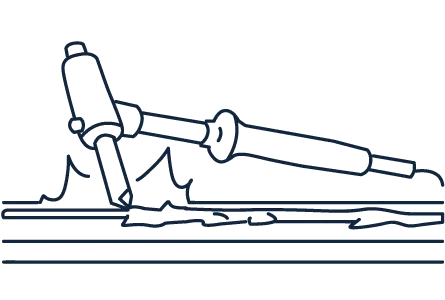

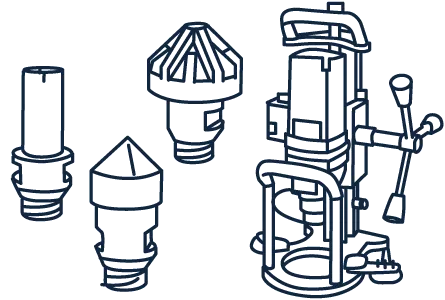

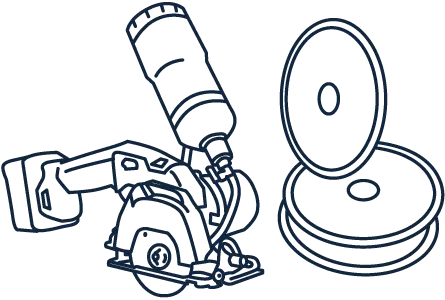

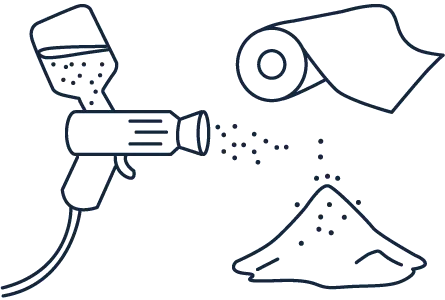

First clean the areas where the adhesive plates are used. Cleaners containing isopropanol, such as the Bohle special cleaner, are best suited for this. Remove the protective film from the mirror plates. Glue the sheets to the back of the mirror at a distance of 10 cm from the edge of the mirror. Drill the holes in the wall to match. The mirror suspension should be located in the upper third of the mirror. Glue the mirror sheet to the mirror, making sure that there are no air pockets in the adhesive, and press the sheets down evenly for at least 10 seconds. The adhesive will begin to bond after 30 minutes. We recommend waiting a further 24 hours at room temperature to ensure that the adhesive has fully cured. With large mirrors, magnets ensure a fixed distance from the wall and thus prevent dangerous tilting.

First clean the areas where the adhesive plates are used. Cleaners containing isopropanol, such as the Bohle special cleaner, are best suited for this. Remove the protective film from the mirror plates. Glue the sheets to the back of the mirror at a distance of 10 cm from the edge of the mirror. Drill the holes in the wall to match. The mirror suspension should be located in the upper third of the mirror. Glue the mirror sheet to the mirror, making sure that there are no air pockets in the adhesive, and press the sheets down evenly for at least 10 seconds. The adhesive will begin to bond after 30 minutes. We recommend waiting a further 24 hours at room temperature to ensure that the adhesive has fully cured. With large mirrors, magnets ensure a fixed distance from the wall and thus prevent dangerous tilting.

How many kilos does a mirror plate weigh?

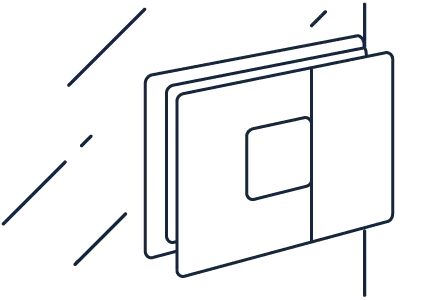

The load-bearing capacity of self-adhesive mirror sheets depends on their size. For example, a 45 x 45 mm mirror sheet can carry approx. 1 kg, while a 100 x 200 mm mirror sheet can carry 12 kg. A maximum of two load-bearing mirror sheets are used per mirror.

The load-bearing capacity of self-adhesive mirror sheets depends on their size. For example, a 45 x 45 mm mirror sheet can carry approx. 1 kg, while a 100 x 200 mm mirror sheet can carry 12 kg. A maximum of two load-bearing mirror sheets are used per mirror.

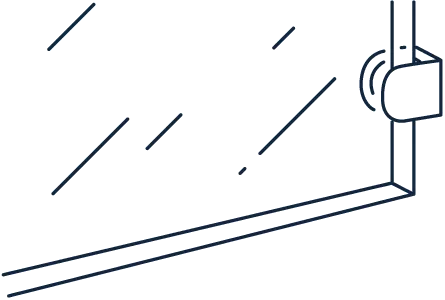

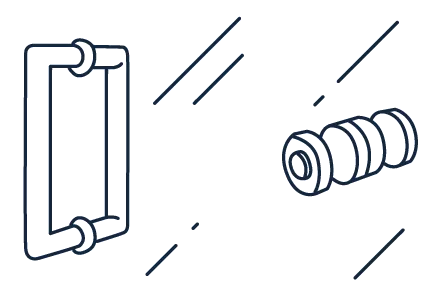

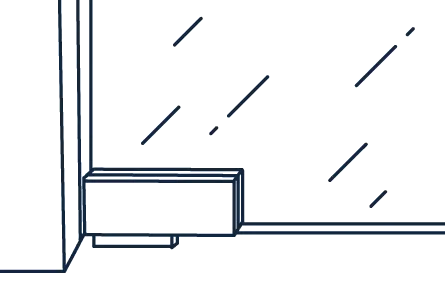

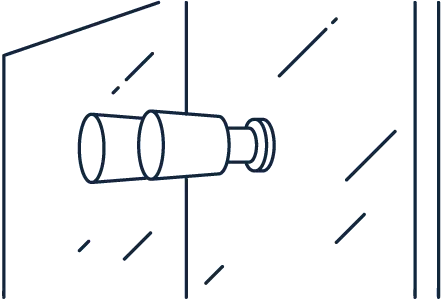

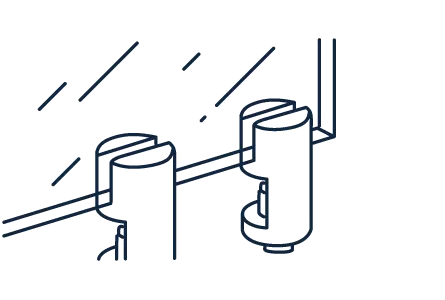

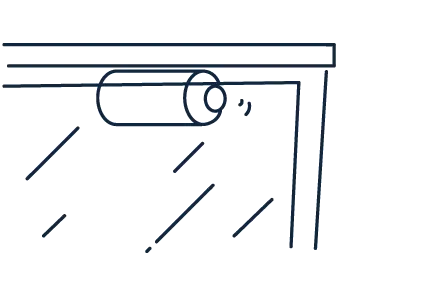

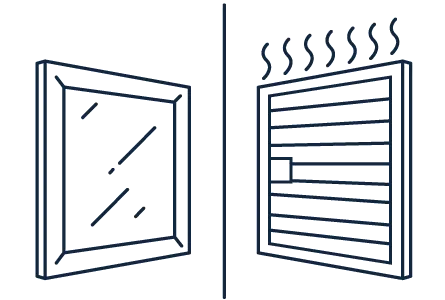

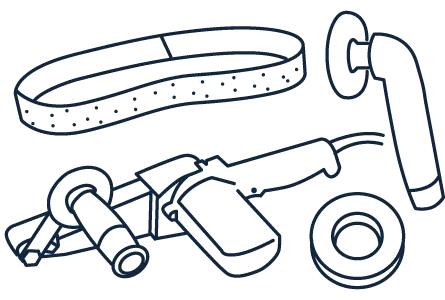

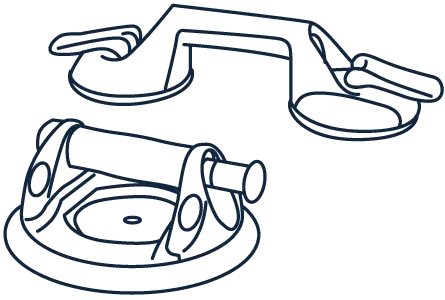

Why are there magnets in many mirror mounting sets?

In addition to mirror plates, some mirror mounting sets contain magnets, e.g. our safemax sets. However, they have no load-bearing effect. Their attachment merely ensures that the mirrors do not tilt on the wall, but are also fixed to the wall at the bottom. Alternatively, press studs are used in the safeclix sets instead of magnets.

In addition to mirror plates, some mirror mounting sets contain magnets, e.g. our safemax sets. However, they have no load-bearing effect. Their attachment merely ensures that the mirrors do not tilt on the wall, but are also fixed to the wall at the bottom. Alternatively, press studs are used in the safeclix sets instead of magnets.

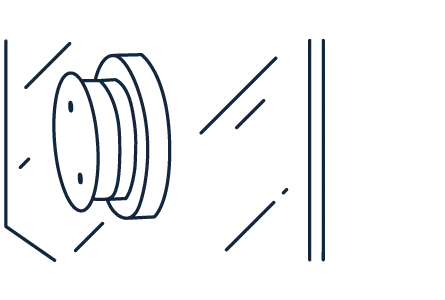

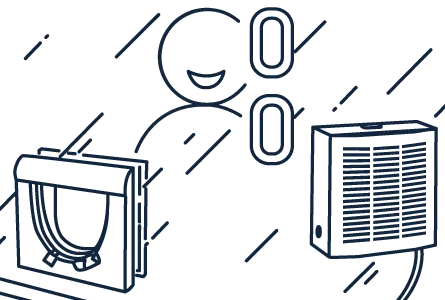

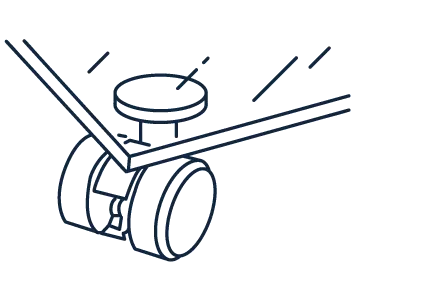

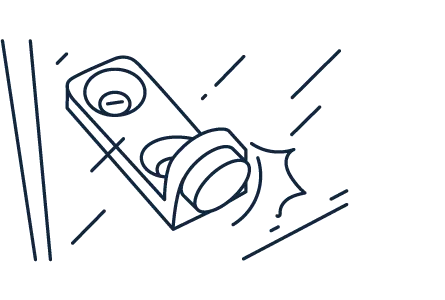

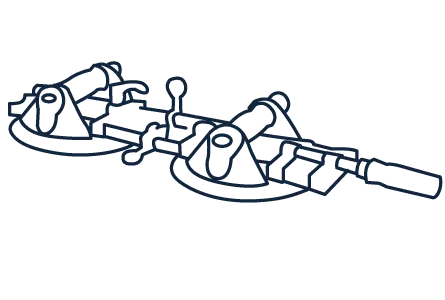

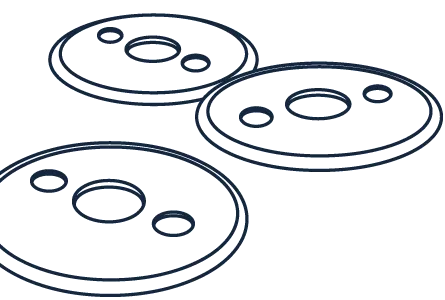

What are eccentric discs used for when attaching mirrors?

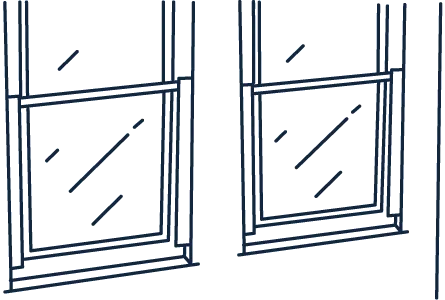

Eccentric discs help to align mirrors. They are placed under the screws that are screwed into the wall. Thanks to eccentric discs, mirrors can also be adjusted by +/- 4 mm after suspension, e.g. if the mirror does not hang evenly horizontally. You can change the height by turning the discs.

Eccentric discs help to align mirrors. They are placed under the screws that are screwed into the wall. Thanks to eccentric discs, mirrors can also be adjusted by +/- 4 mm after suspension, e.g. if the mirror does not hang evenly horizontally. You can change the height by turning the discs.

How long do I have to wait before I can hang mirrors with adhesive plates?

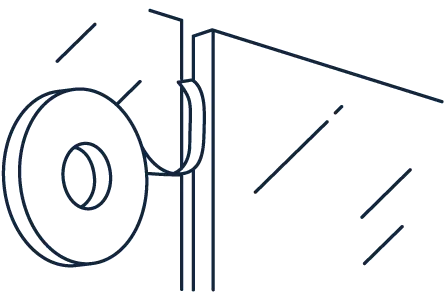

The golden rule of mirror mounting is 10 - 30 - 10. The adhesive plate should be pressed firmly onto the mirror for 10 seconds. This is followed by 30 minutes resting time. Before the mirror is finally hung up, we recommend pressing the mirror plates on a second time for 10 seconds.

The golden rule of mirror mounting is 10 - 30 - 10. The adhesive plate should be pressed firmly onto the mirror for 10 seconds. This is followed by 30 minutes resting time. Before the mirror is finally hung up, we recommend pressing the mirror plates on a second time for 10 seconds.