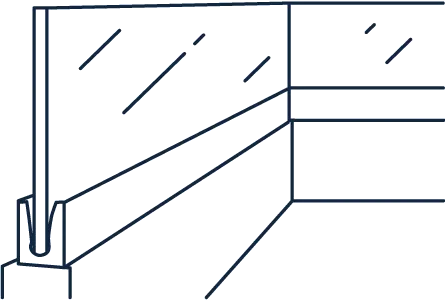

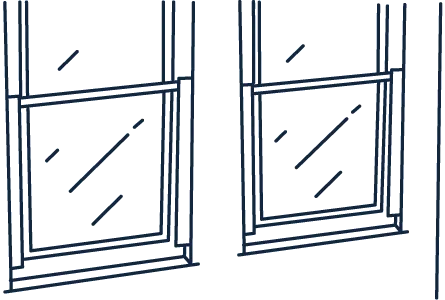

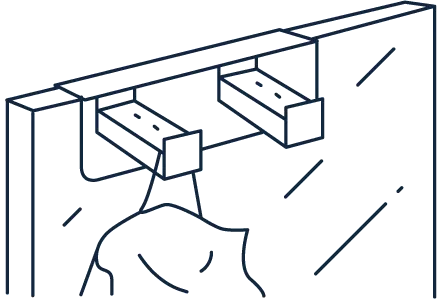

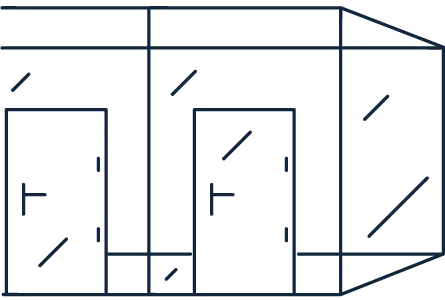

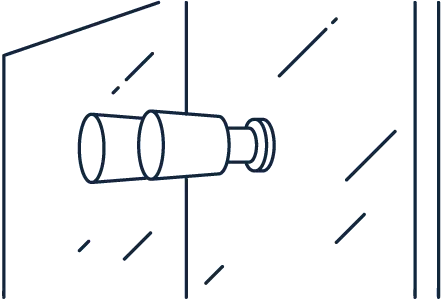

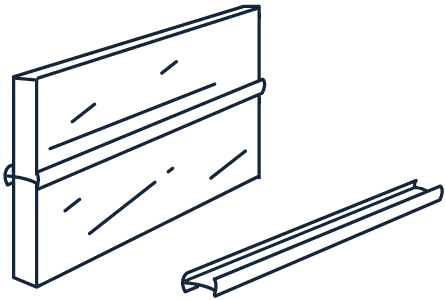

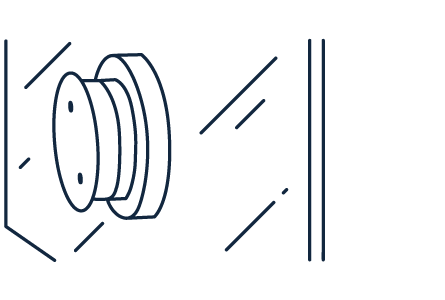

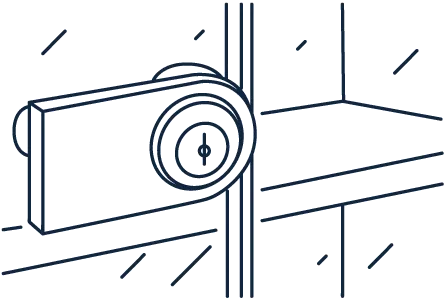

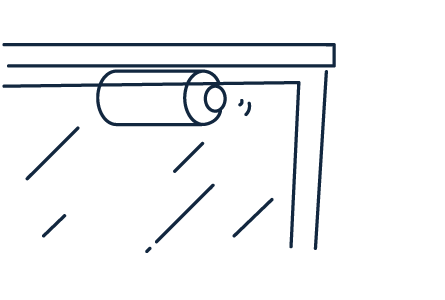

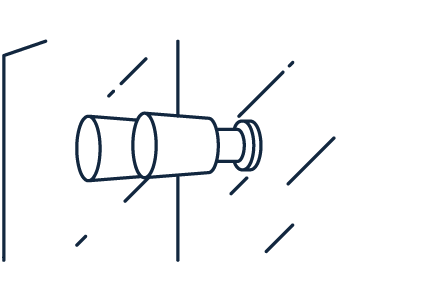

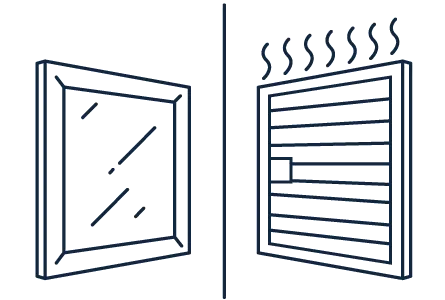

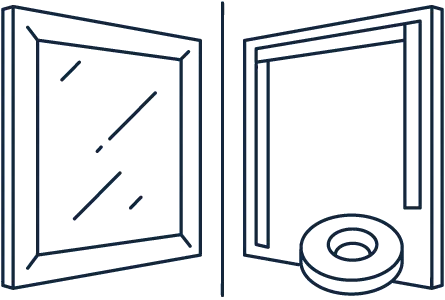

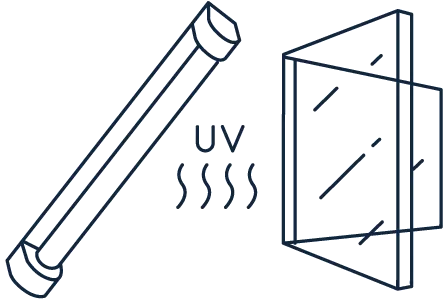

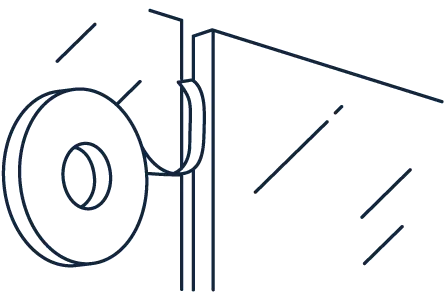

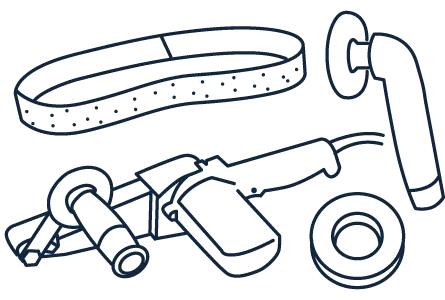

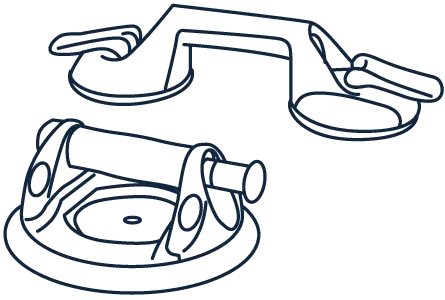

Glass fittings

Glass fittings

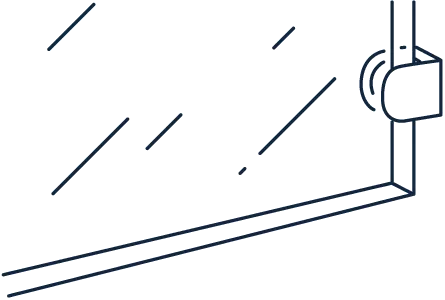

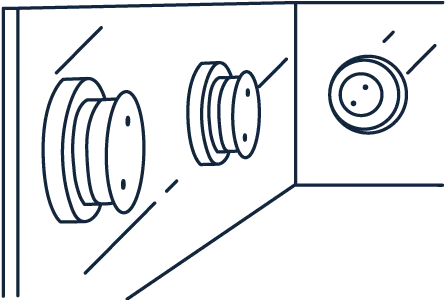

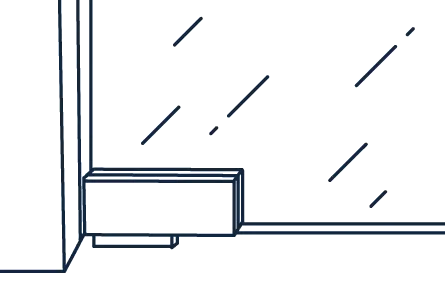

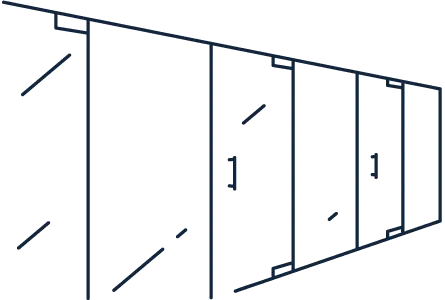

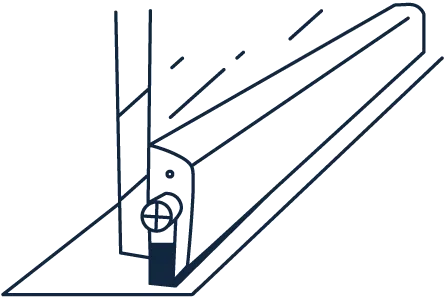

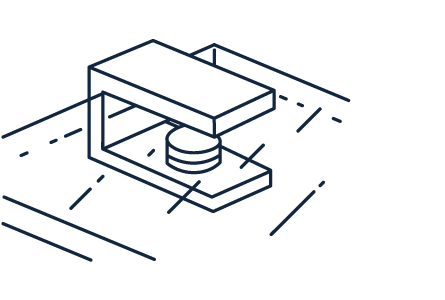

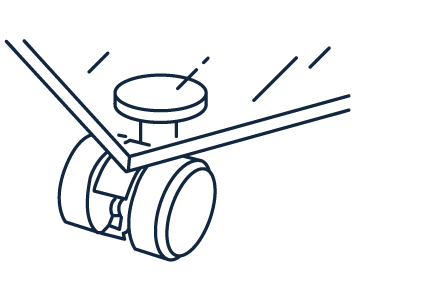

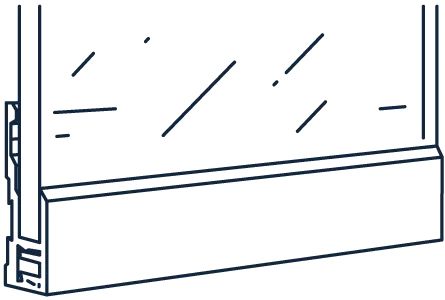

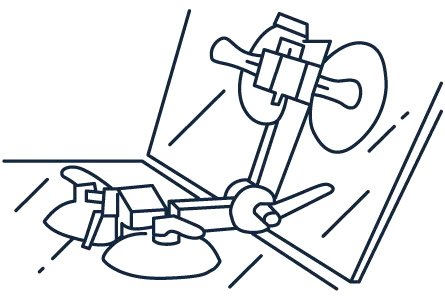

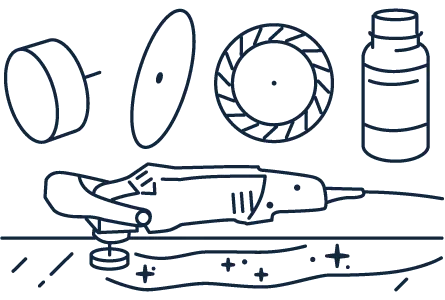

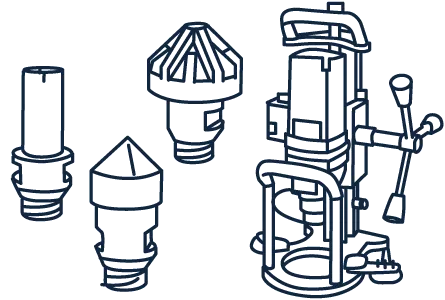

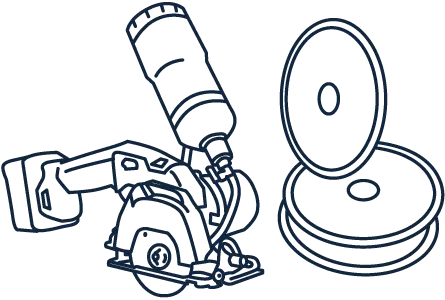

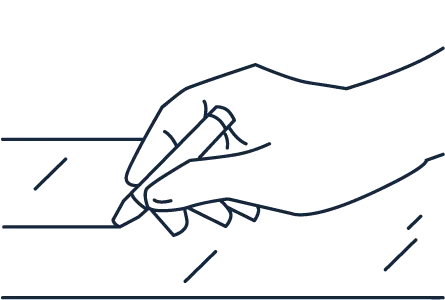

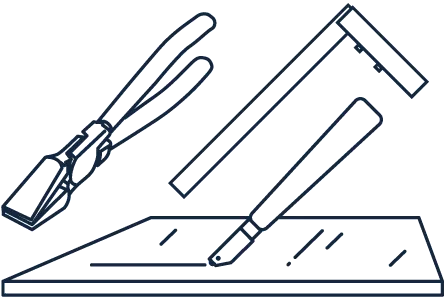

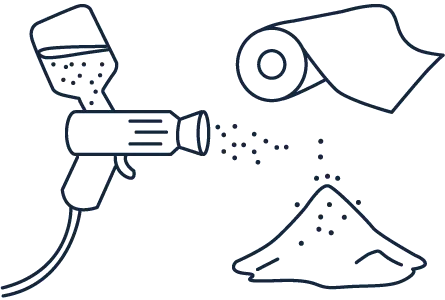

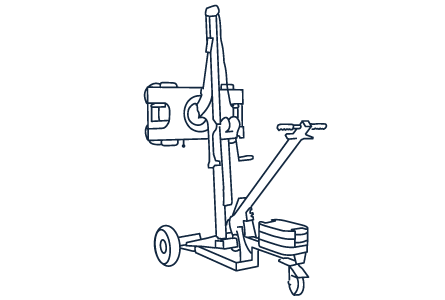

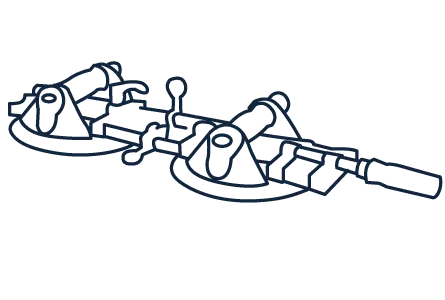

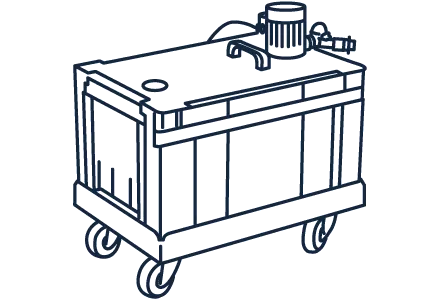

Workshop supplies

Workshop supplies