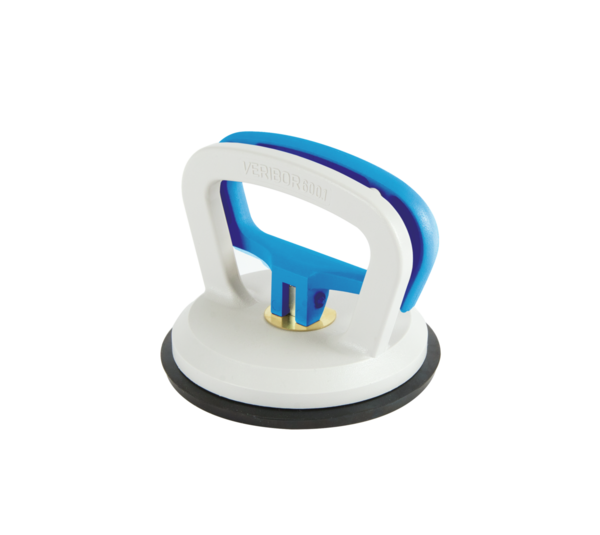

Veribor® Premium Suction Lifter: Safety as standard.

Veribor® at a glance

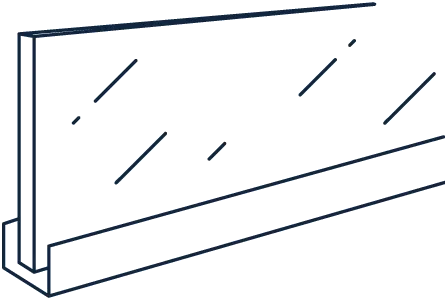

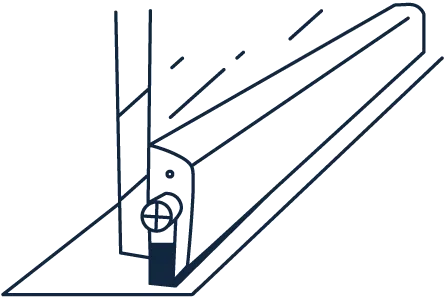

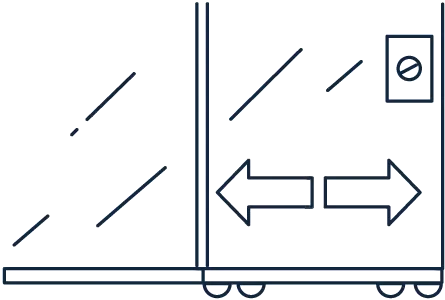

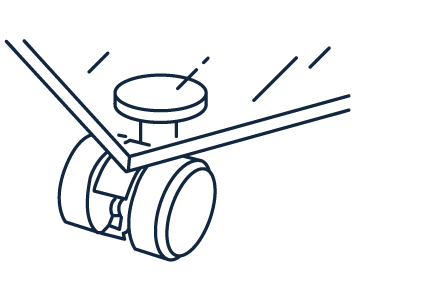

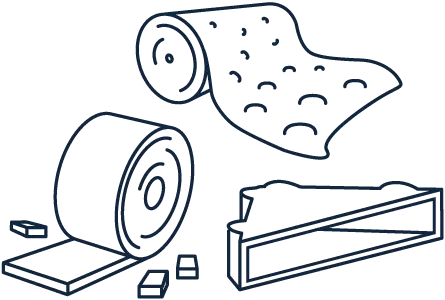

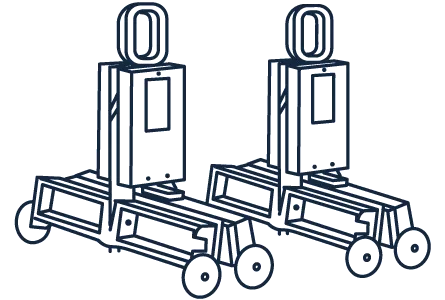

- For the transport of all construction elements and objects with a gas-tight surface

- With a load capacity from 25 kg to 120 kg

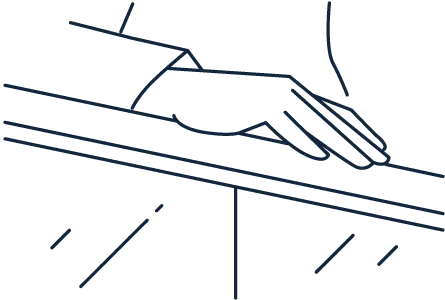

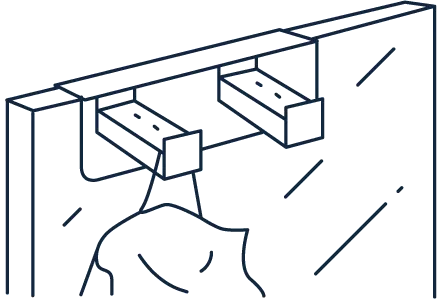

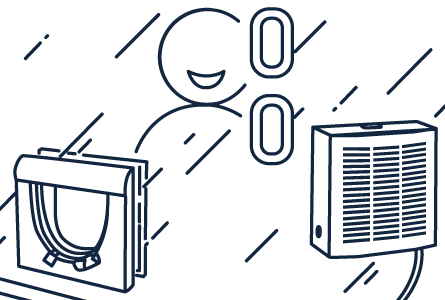

- For ergonomic, back-friendly lifting and carrying of bulky, heavy building elements

- For lower costs due to less transport damage

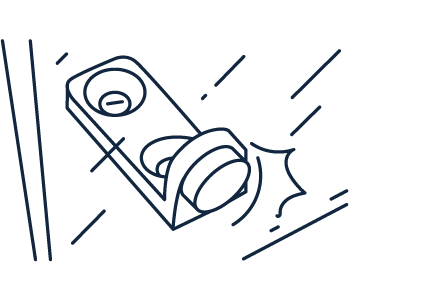

- For more grip safety through increased carrying comfort

- The right Veribor® model for every surface and every material

- User-friendly due to intuitive design

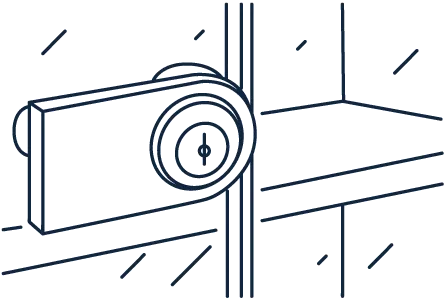

- With double safety due to 2-fold safety factor

- Compact, light and handy

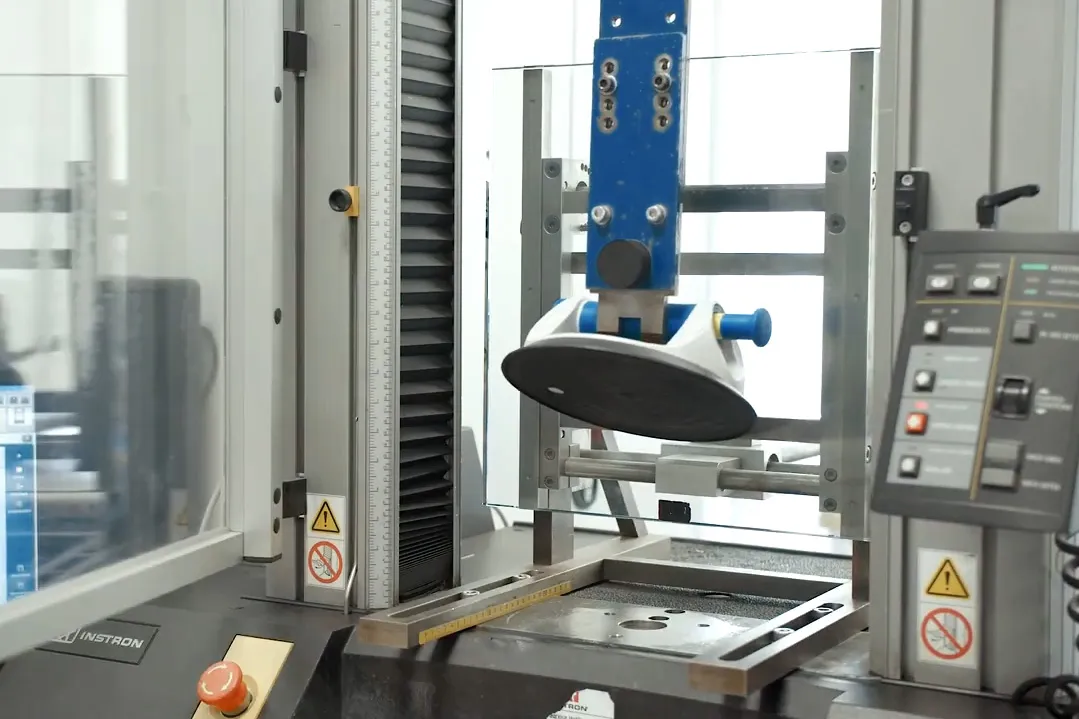

A look behind the scenes: Development, production and quality testing

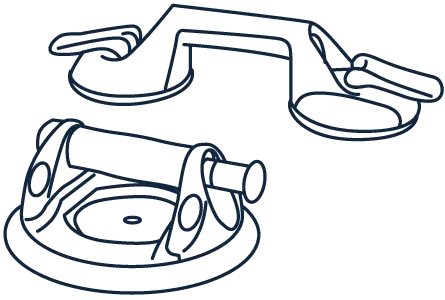

Aluminium and plastic. Two types. One goal.

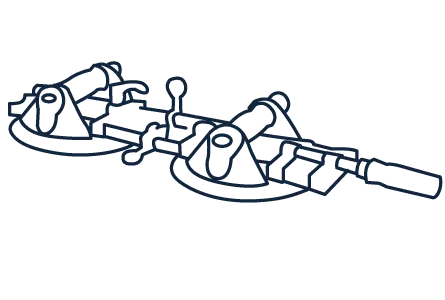

At Bohle, we have developed two Veribor® suction lifter series: Aluminium and Plastic. The most important thing about them is not their difference, but their commonality. Regardless of whether working with aluminium or plastic suction lifters is preferred: All Veribor® suction lifters meet our standards of quality, safe working and ease of work.

They are not only Made in Germany, but also Made by Bohle. Because we know that our lifting and carrying devices have to withstand a lot, we only use materials that enable us to meet this high standard. And we give you the choice.

Aluminium series

Plastic series

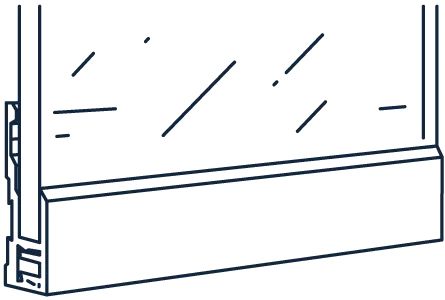

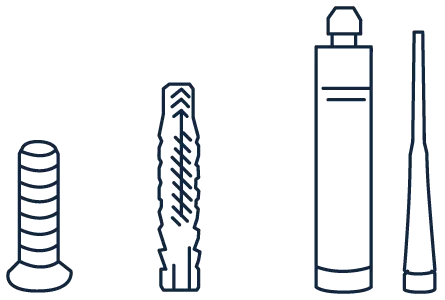

Plastic is a lighter base material compared to aluminium. Despite its light weight, the plastic we use for the Veribor® series is very robust, impact-resistant, and withstands the highest loads. Not only do we continuously test this, but it is also evident from the fact that the same plastic is used in motorbike helmets.

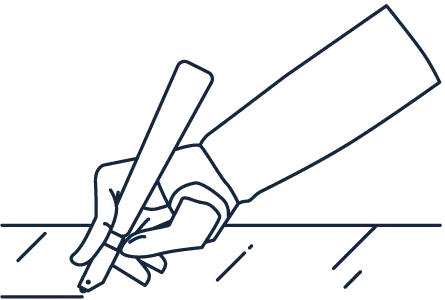

Due to its texture and mouldability, more design details can be implemented with this plastic. We use this in our Veribor® plastic series primarily to highlight important safety details. Very important: the plastic is - just like the rubber pads - PAH-free, i.e. it does not contain any carcinogenic hydrocarbon compounds. Since the material is also heat, oil, UV and weather resistant, it is ideal for use in the trades.

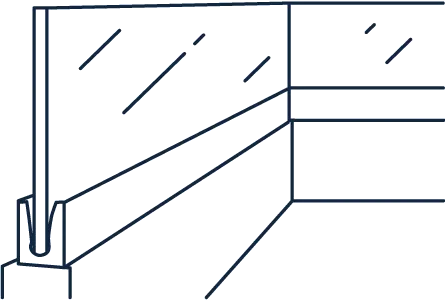

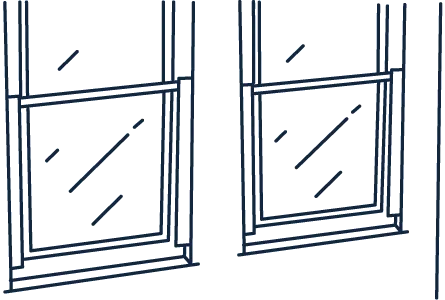

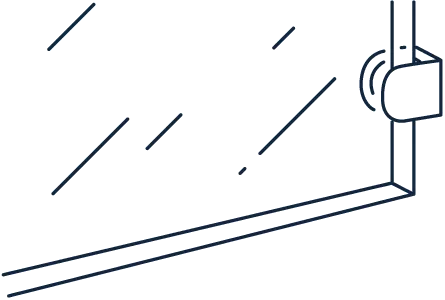

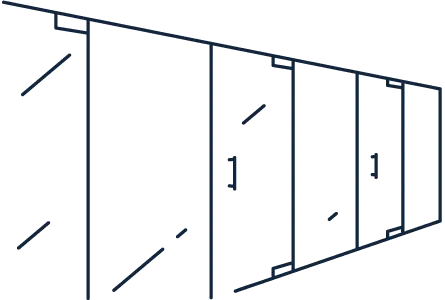

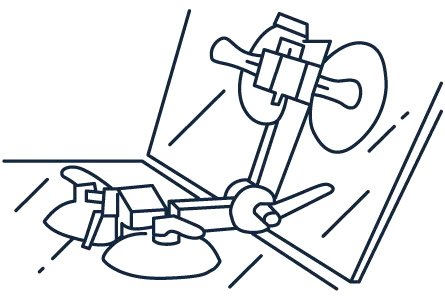

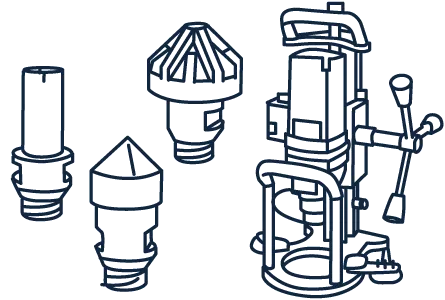

Applications

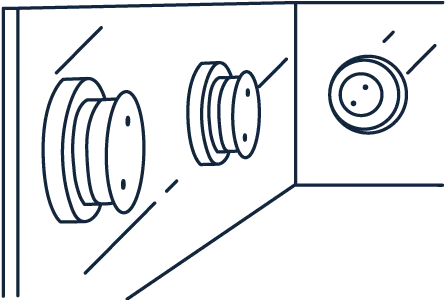

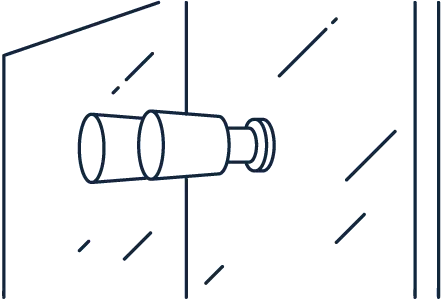

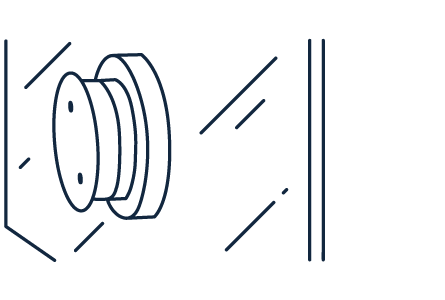

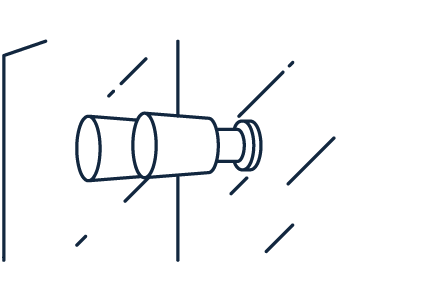

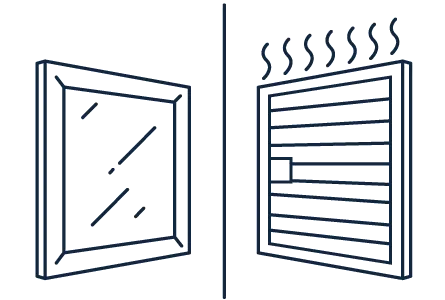

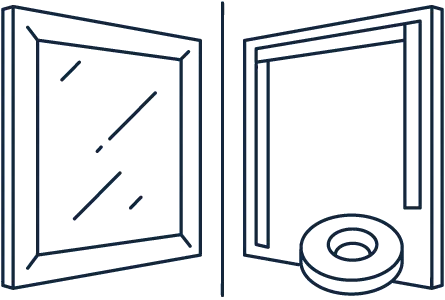

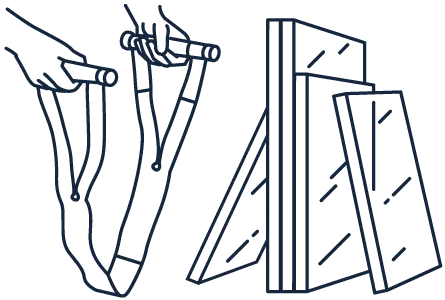

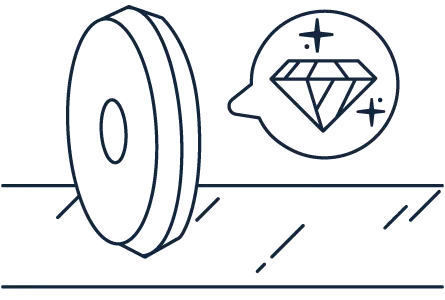

Every surface has different properties, every object different requirements. For absolute work safety and the highest user comfort, different suction lifters are needed.

Why are there different Veribor® models?

Why do we develop different suction pads?

Quality guarantee

The brand

- "Ver" is the first syllable of the French word for "glass": verre

- "ib" stands for the initials of the company founder and inventor Josef Bohle. For the sake of simplicity, the letter j was replaced by an i.

- "or" symbolises the connection to the first company headquarters in the Solingen district of Ohligs, Rhineland.

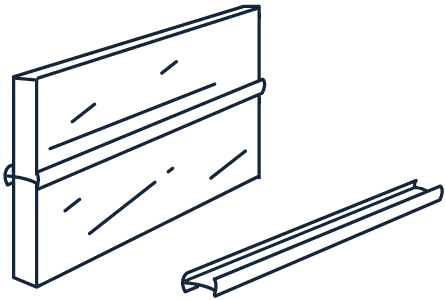

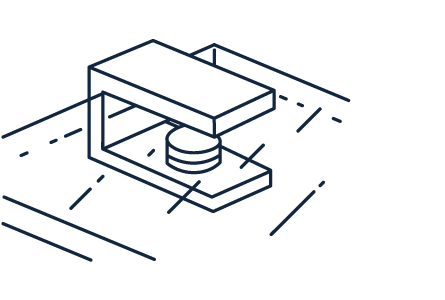

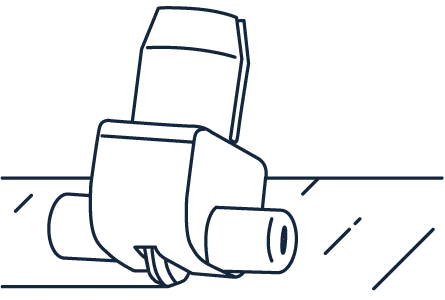

Special solutions

Where the versatile standard applications with Veribor® suction lifters are not enough, our team of experts comes into play.

In close cooperation with you, an experienced team of engineers and technicians will be happy to develop special designs to meet your practical needs: from specific individual solutions to system solutions for large plants, for optimising individual handling processes or entire production sequences - also integrated into a wide variety of series products. Ask us!