UV glass bonding with Bohle

Professional UV bonding with components from Bohle for:

- Glass furniture and pane bonding

- Glass crafts

- Glass display cabinets and tables

- Geometric-shaped glass

- Glass-glass bonding

- Glass-metal bonding

As a pioneer with over 30 years of experience in glass bonding...

Step by step to perfect glass-glass bonding

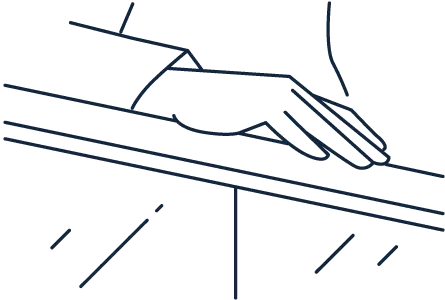

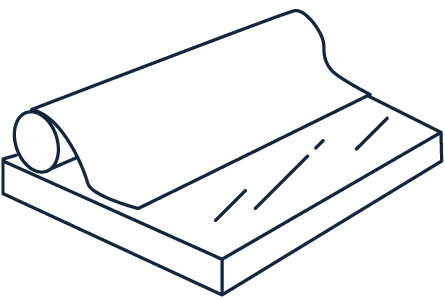

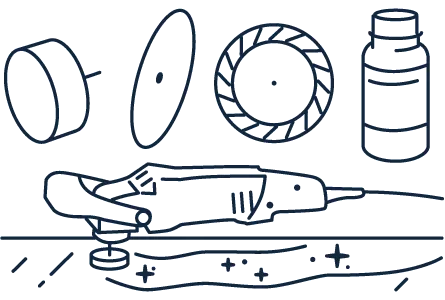

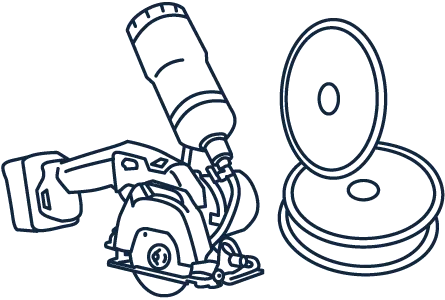

STEP 1 - Cleaning and surface preparation

The most important preparatory work is cleaning the edges and surfaces of the glass to be bonded. Only with absolutely clean surfaces can an optimal result be achieved with UV bonding. Therefore, clean all bonding surfaces with our Bohle special cleaner for UV bonding and a lint-free cloth. All surfaces will then be clean, grease-free and dry. The cleaner used must not leave any residue.

Our professional practice tip: For some materials, normal surface cleaning is not enough. As a professional, you know that. To ensure perfect adhesion with our UV adhesives, more intensive pre-treatment is necessary in these cases. At Bohle, we also have suitable components for this. Just ask us!

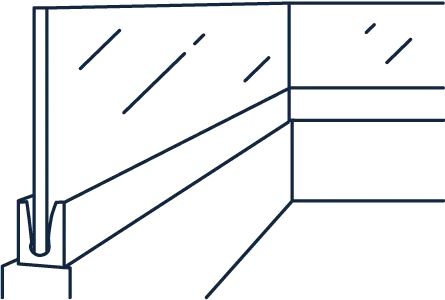

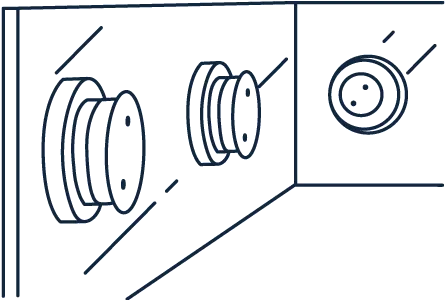

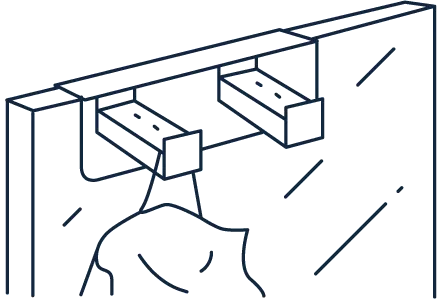

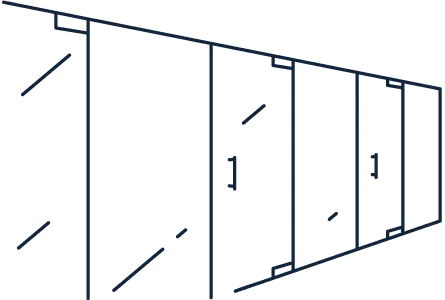

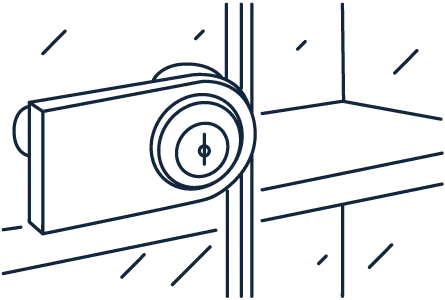

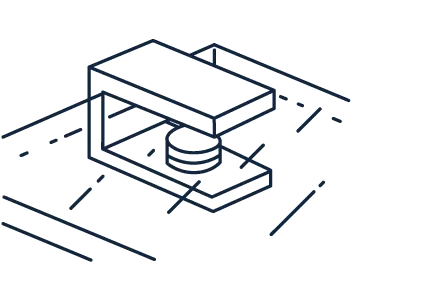

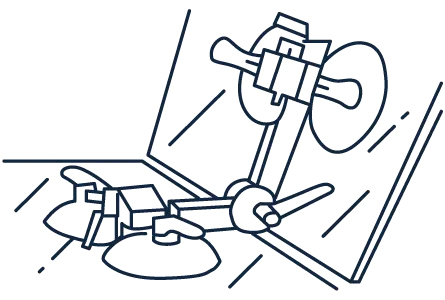

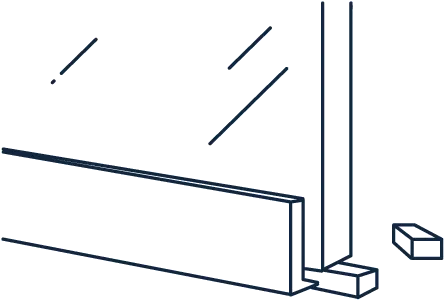

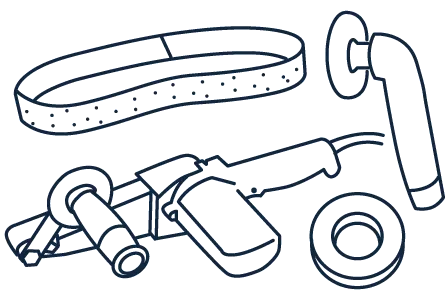

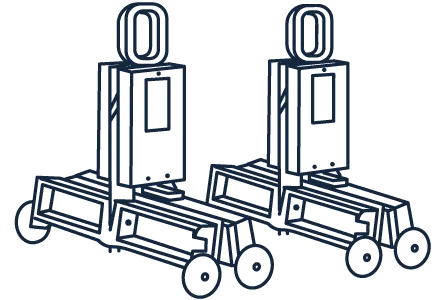

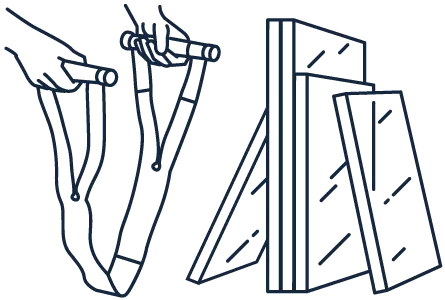

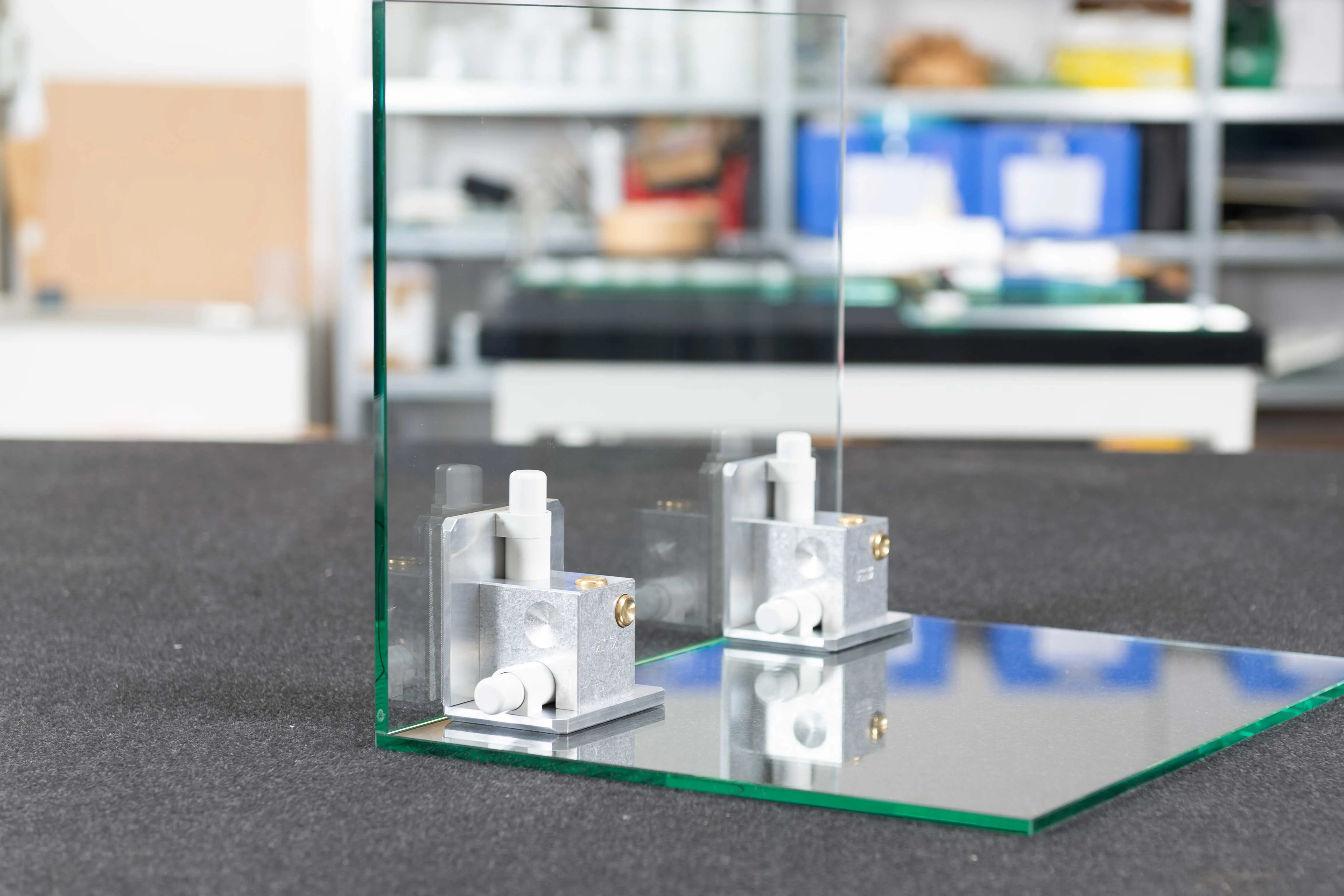

STEP 2 - Positioning and fixing

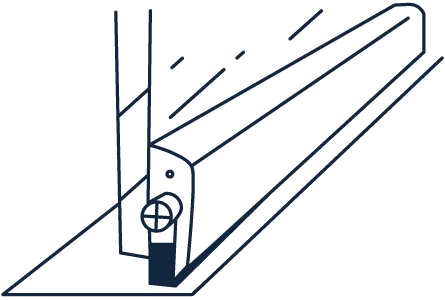

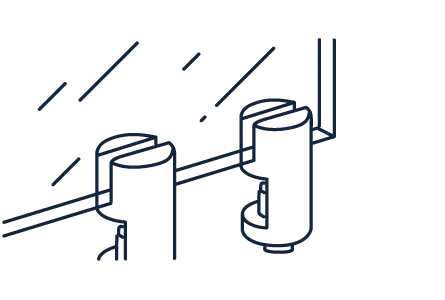

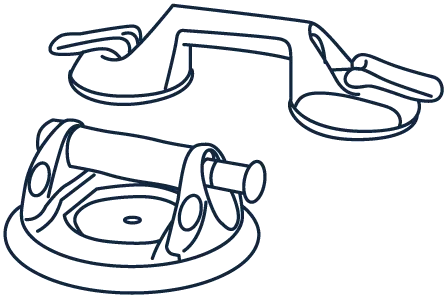

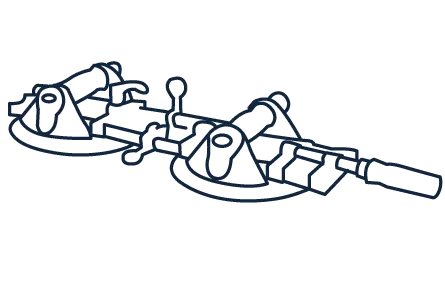

Due to the evaporation coldness, the surfaces of the glass elements are slightly cooled down after cleaning. Therefore, before fixing the two glass elements and applying the UV adhesive briefly heat the cleaned surfaces to 20-30 Kelvin above room temperature using a hot air device. In order to position two glass elements exactly and to fix them during the bonding process, you need suitable fixing aids. These are important to secure the individual parts to be bonded against vibrations or slipping. This is because the UV adhesive polymerises during the curing process and forms a network. Inadequate fixing of the bonded parts can, in case of doubt, lead to this network being damaged, and that in turn leads to a loss of strength. Important: You can only achieve the desired professional end result by using high-quality fixing aids.

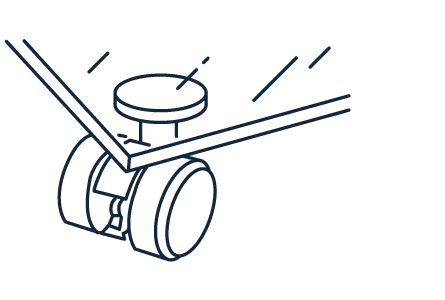

Our professional practice tip: Our specially developed VERIFIX® fixing aids are an important component in UV bonding, as they enable a wide variety of positioning of the glass elements and prevent vibrations and slipping, even in more demanding bonding positions.

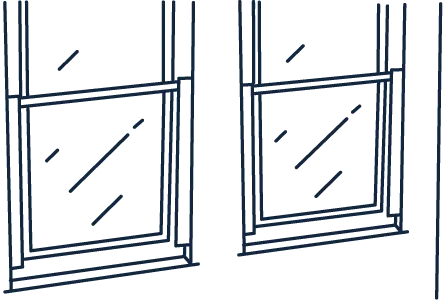

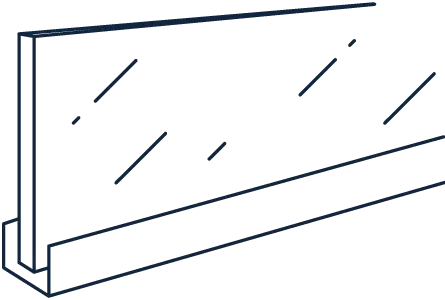

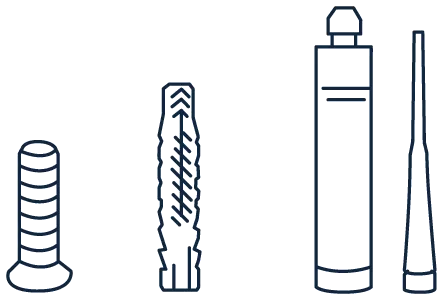

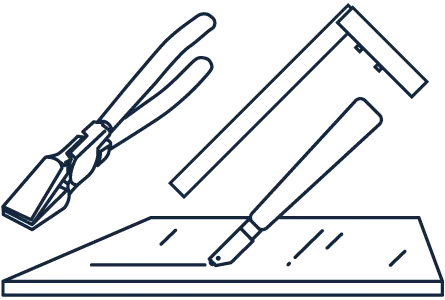

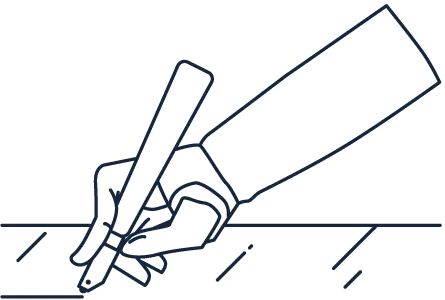

STEP 3 - The UV adhesive: selection and processing

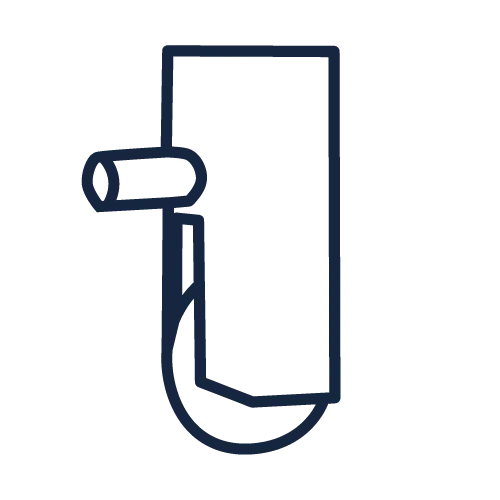

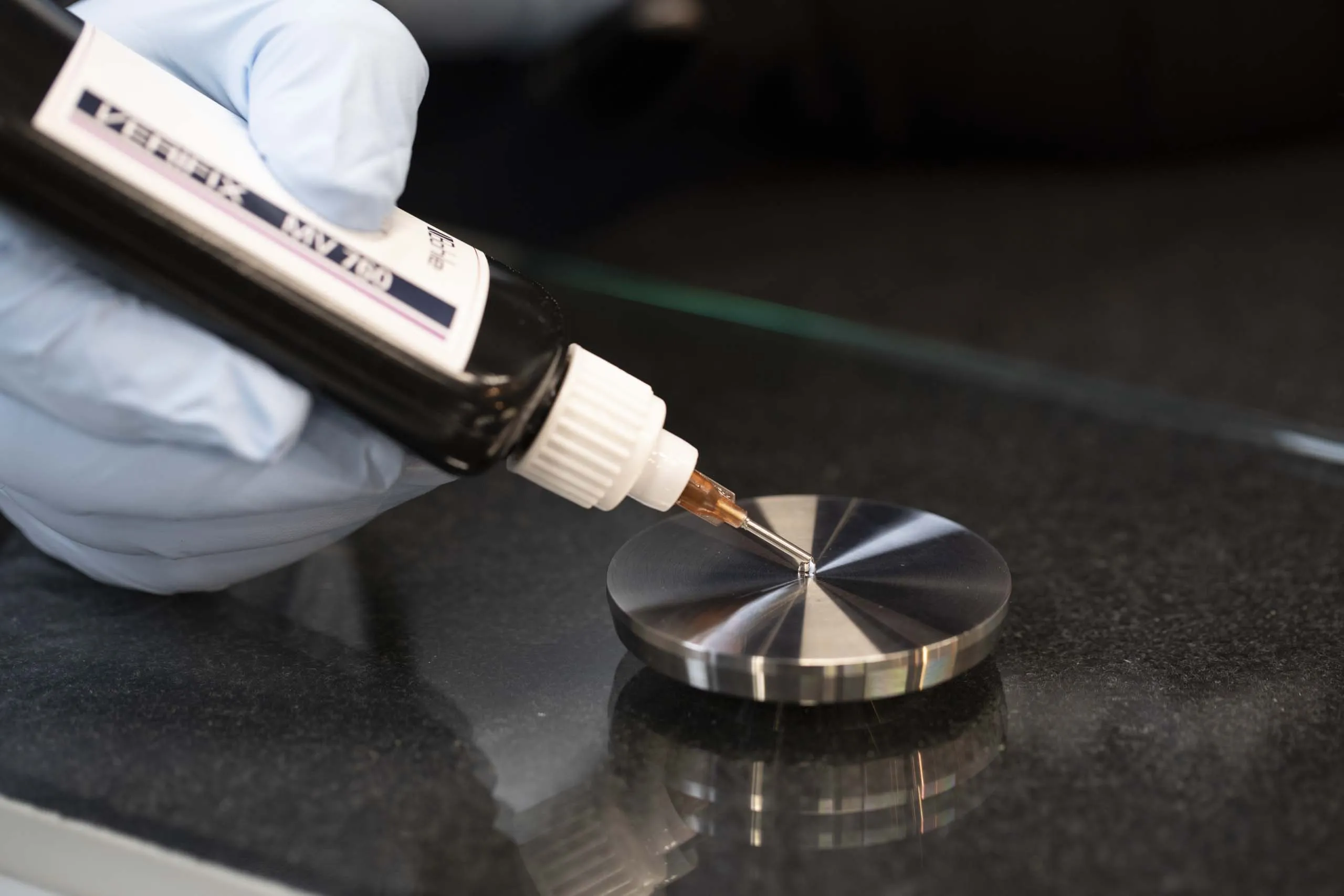

We have developed various adhesives for glazier applications. The choice of the right adhesive for your project depends on the material combination, the environmental conditions and the expected future loads on the finished construction. In addition to low-viscosity, capillary adhesives, we also have medium-viscosity, impact-resistant or elastic adhesives in our range. If moisture or UV radiation are to be expected, correspondingly resistant adhesive types must be used. Once you have selected the appropriate capillary UV adhesive, insert the dosing needle of the bottle directly into the seam between the two glass elements and wih the help of the needle apply the adhesive over the entire length of the joint.

Our professional practice tip: Good to know: Our one-component adhesives are highly transparent after processing and curing. In addition to easy and clean processing, this is a significant plus point for modern, chic glass furniture and glossy glass objects.

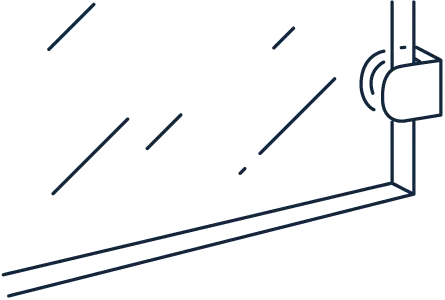

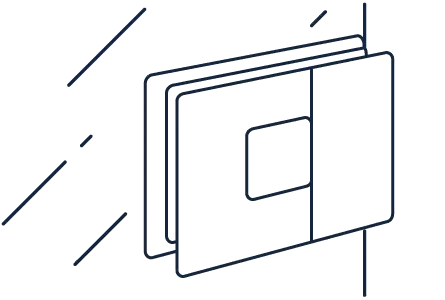

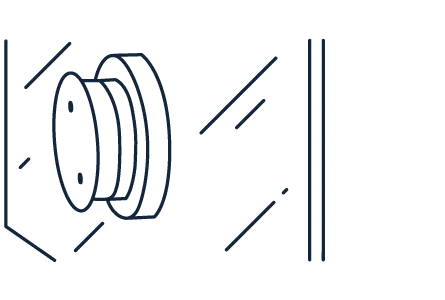

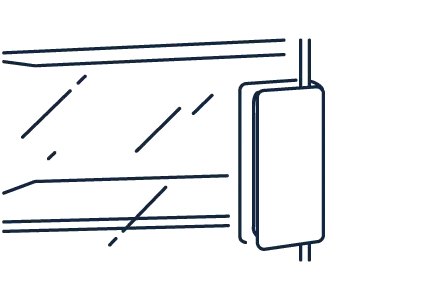

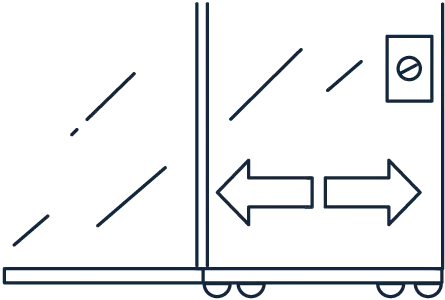

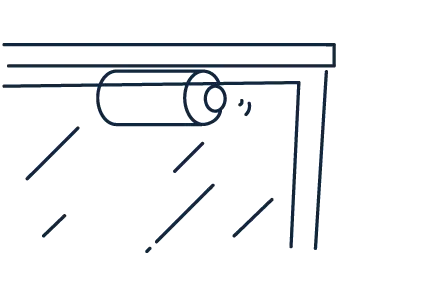

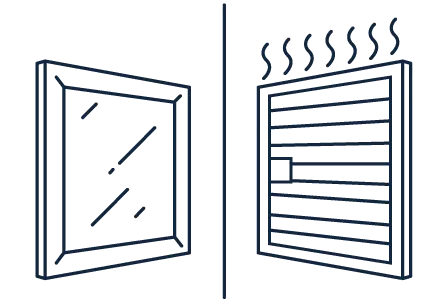

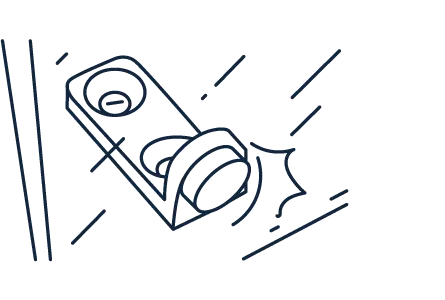

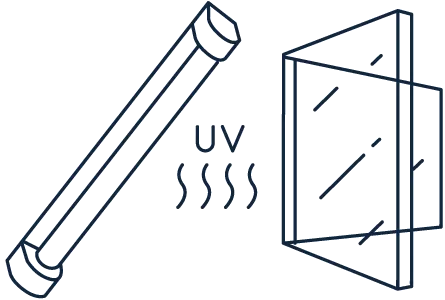

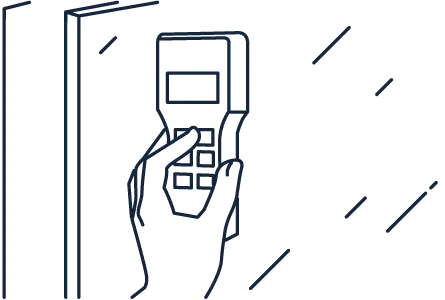

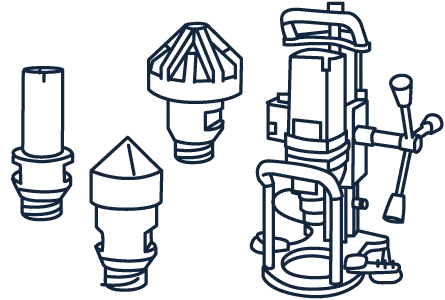

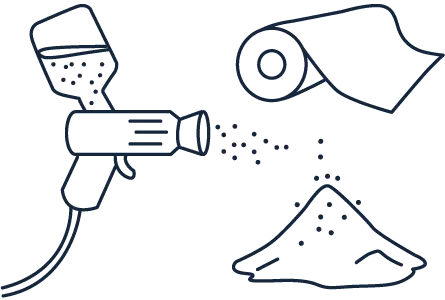

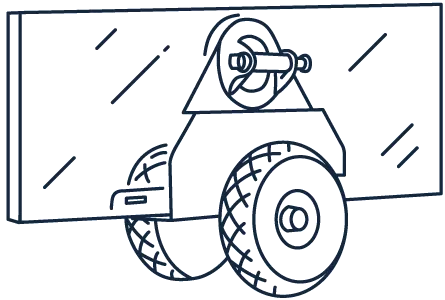

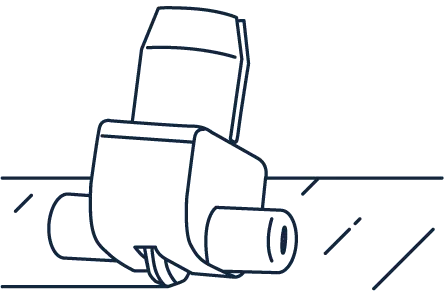

STEP 4 - Curing with UV radiation

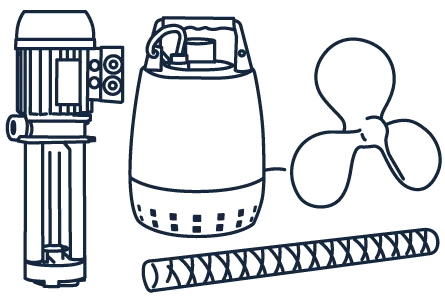

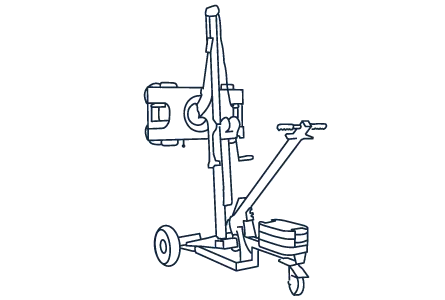

One of the last steps is to cure the adhesive with a suitable UV light. Always select your UV lamps according to the area size of the bond, to achieve an even and simultaneous exposure of the entire bonding surface. This ensures that the adhesive cures evenly and prevents unintentional uneven stresses from building up in the bond, which can cause the bond to fail. Hand lamps are particularly suitable for bonding metal parts or short adhesive edges. For longer edges, tubular lamps or elongated UV lamps in the appropriate size are the right choice. The Twin-LED is a practical and mobile solution for curing smaller surfaces. You will find UVA lamp systems for curing UV adhesives in all variants in our range. Of course, they are all equipped with special filter screens to prevent damage to skin and eyes.

Our professional practice tip: If the elements to be bonded are opaque or there are chemical incompatibilities due to the combination with the Bohle UV adhesive, simply use our 2K construction adhesive as an alternative solution.

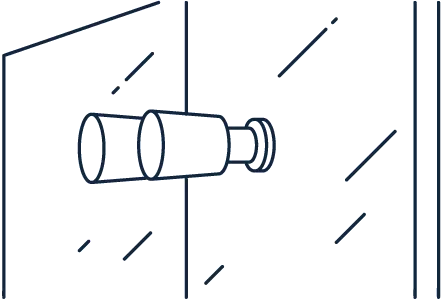

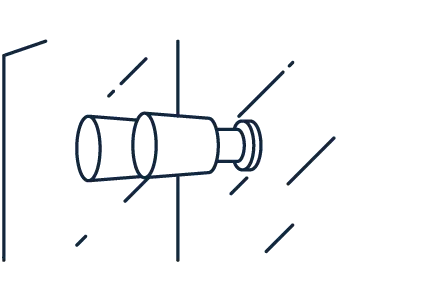

UV bonding of glass-metal joints

A combination of glass and metal elements is very common in glass furniture construction. We also make this connection possible with our adhesives. Some of our UV adhesives are also perfectly suited for these constructions. Our professional explains the special features that need to be taken into account in the practical video.Step by step to perfect glass-metal bonding

The right solution for every bond

- Glass with wood

- Glass with stone

- Glass with thermoplastics

- Coloured glass and VSG

- Adhesive bonds with increased exposure to moisture

Glass bonding - product overview

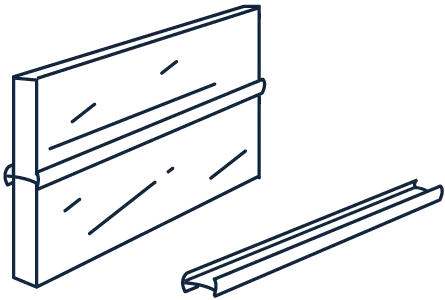

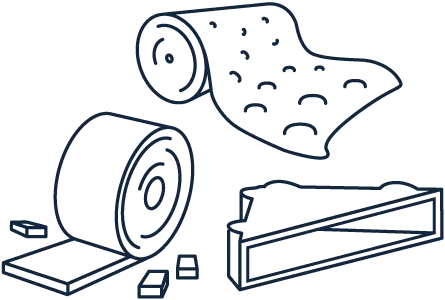

- VERIFIX® fixing aids

- UV-curing adhesives

- 2K - construction adhesives

- UV - exposure lamps

- Auxiliaries for UV glass bonding

- Fittings

We offer Level 1 UV bonding training in our Showroom & Training suite in Cheshire.