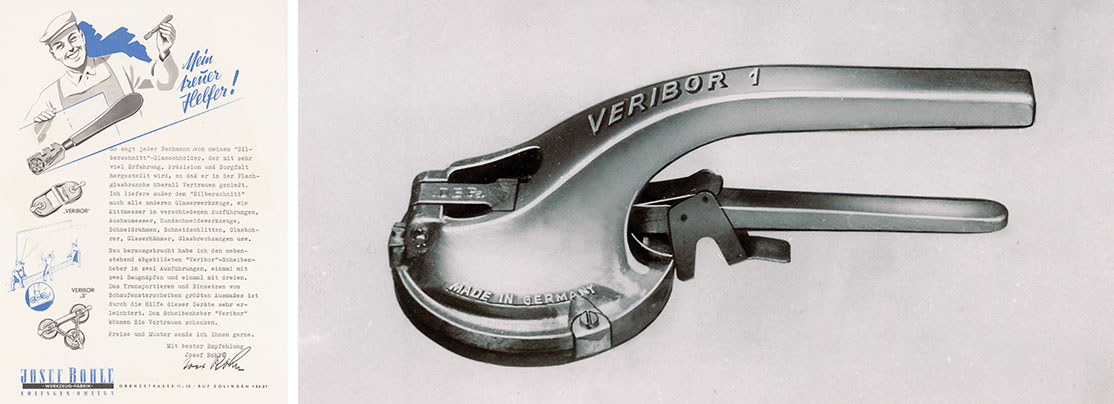

Be safe, be sure with Veribor®

The premium aluminium and plastic suction lifters

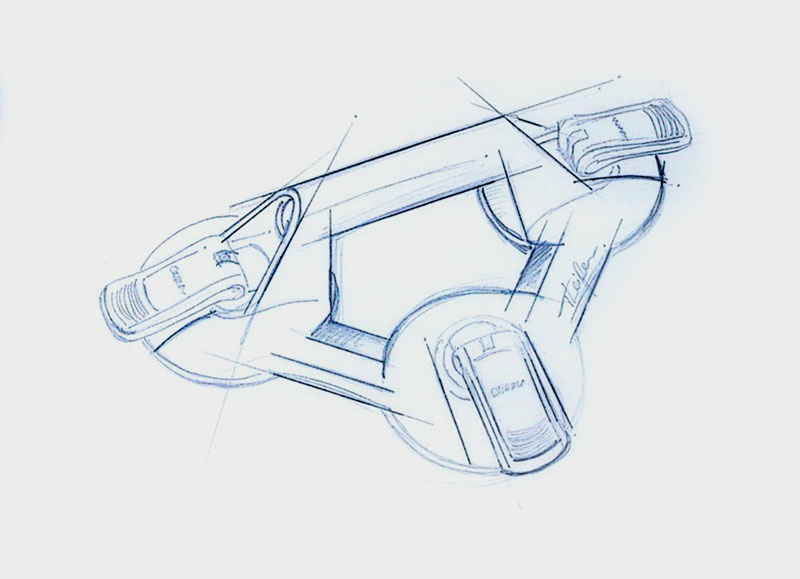

Suction lifters made of aluminium are sturdy and extremely durable. Veribor® quality products require ongoing refinement to adapt to new application needs and thus make work easier. Comfort, ergonomics, and design are the driving forces of the new Aluminium Series which leaves nothing to be desired. While the wide distance between the suction heads underlines the sturdy construction of the product, the minimalist design demonstrates clear-cut lines.

Our Bohle in-house developments require team spirit. It needs the joint efforts of the Manufacturing, Industrial Design and Product Management divisions to finally achieve the highest degree of functionality, shape, and safety.

(1) Safe

Thanks to the larger suction heads, the pressure is ideally distributed along the outer suction pad area.

(2) Sturdy

The large washer enables an ideal distribution of force and in this way increased stability for the levers.

(3) Good grip

The grip with its wider diameter rests comfortably in the hand and offers a large grip area thanks to its raised position.

(4) Custom-fit

Depending on the application, simply turn the third lever by 90°, which will reduce the width of the suction lifter. The lever can be locked in three positions in total.

(5) Easy to operate

The wide contact area of the levers enables an optimum distribution of force and makes engaging the lever as easy as can be – no matter whether this is done with the thumb or the palm of the hand.

The Veribor® Aluminium Series

Experience pays off

“The word handicraft is not a coincidence. Veribor® users indeed work with their hands. We support them in what they do with efficient tools. Our aim was to develop an aluminium suction lifter which stands out from all other suction lifters in the market. We literally wanted to redefine the product. And not only as far as its visual appearance is concerned. We rather put an emphasis on comfort and ergonomics when doing handicrafts”,

— says product Dipl. Industrial Designer Marco Theissen.

The right suction lifter for every application

From the beginning of Veribor® production in the mid-50s until today, Bohle has manufactured more than 200 different types of premium suction lifters and fixing aids. They all have their specific fields of application depending on carrying capacity and the surface to be transported. Bohle has a suitable solution for each sector and each industry: glaziers, carpenters, metalworkers, interior fitters, tilers, window builders, installing companies, gardening and landscaping companies, automotive companies, fitters, and many more. There is one thing, however, that all Veribor® suction lifters have in common: the highest standards of safe working.

- Solid construction made of high quality aluminium – definitely without lead alloys.

- Although the aluminium extraction requires a lot of energy, the light metal can be completely melted down and reused.

- We use resilient and impact-resistant plastic which is capable to withstand highest loads and is therefore also used for motorcycle helmets. It is not only heat, oil, and weather-resistant, but also PAH-free.

- Moveable elements stand out visually and make operation as intuitive as can be for you.

- The secret behind the rubber disc: We know the right degree of hardness for every application. PAH-free, of course.

- The plastic suction lifters make your daily work easier.

The Veribor® Plastic Series

70 years of engineering art

Veribor® has been a quality brand of Bohle Group since 1953. This unique product development expertise is based on decades of experience. The sophisticated vacuum technology together with a special focus on safety and ergonomics is what our products stand for. When it comes to the selection of raw materials and gentle manufacturing processes, Bohle complies with highest quality standards.

Made in Germany

It all starts with the in-house production of the rubber pads and ends with the manual assembly of the suction lifters. The production and the corresponding quality assurance take place in Haan, located in the German federal state of North Rhine-Westphalia. Even small individual parts, supplied by long-term partners, come from within a radius of 50 km. The result is a high quality Veribor® suction lifter that keeps its promises.

Convincing safety

Do you work with Veribor® suction lifters on a daily basis? Then it is all the more important that the suction lifters have maximum loadability and guarantee flexible working without risks. Your safety is in our hands. This is why all Veribor® components undergo our own, multi-stage quality checks. This includes, for instance, the separate vacuum check of valve bodies and rubber pads, or the tearing test in which the suction lifter must withstand twice the maximum load. Only if this is the case, the Veribor® suction lifter obtains its tested Bohle approval.