Brand talk: Silberschnitt

Whether it‘s Fulton for umbrellas, Kleenex for tissues or Sellotape for adhesive tape: every company dreams of brands that become synonymous with their product range. Bohle has achieved this: the Silberschnitt®, a pocketsized glass cutter, is the number one for glass processors around the world – and has been an indispensable basis for the success of the medium-sized company from North Rhine-Westphalia for 80 years.

First she threads the cutting wheel onto wire, then guides it carefully over a test piece: Silvia Manjinder meticulously checks every cutting wheel before a Silberschnitt® glass cutter leaves the production hall and is delivered, for instance, to the United Arab Emirates or Argentina. The 48-year-old has been working in quality control at Bohle for 19 years. Her credo: anything that squeaks and wobbles will fly out. ”It needs to have a uniform hum and whirr, feel good in your fingertips and not judder or run unevenly,” states Silvia Manjinder.

Drive for entrepreneurial freedom

Looking good, in the eyes of Silvia Manjinder, means have a silvery shine – and she explains how the tool, synonymous with the core expertise of her employer, got its name: Silberschnitt®. It was named after the shiny silver fissure created within the glass when the high-quality cutting wheel is guided over the glass with the appropriate pressure and the necessary stress, which allows it to be broken precisely along the desired line.

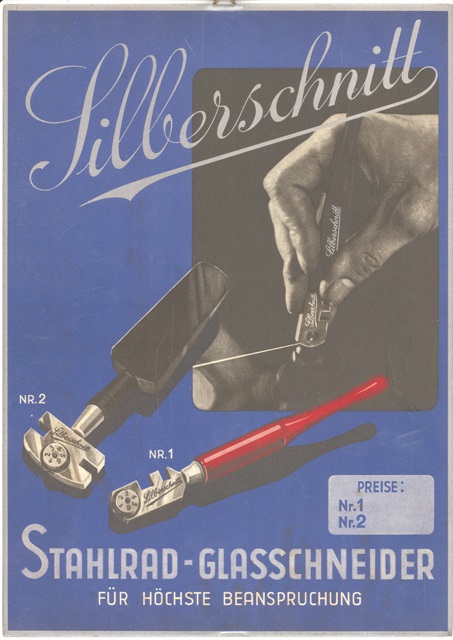

Glass cutters have been included in the product range of the medium-sized company for over 80 years and the classic 100.0 is the bestselling product at Bohle to date. The Silberschnitt® brand is a complete product range today that includes glass cutters made of steel and hard metal with an oil reservoir integrated into the handle, glazing tools, angle holders and templates. The Silberschnitt®, which is much more than merely a tool, is available in many variants. For in a similar manner to Kleenex for tissues or Sellotape for adhesive tape, the Silberschnitt® is generally regarded as being synonymous with glass cutters in many countries around the world. „The Silberschnitt® is the very root of our family business,” states Ulrich Bohle, grandson of the company founder, Josef Bohle. “Without it we wouldn‘t be where we are today.“

The tool shaped the company history at an early stage: In the wake of the economic crisis at that time, locksmith Josef Bohle left his native Westphalia and moved to Solingen, Germany‘s capital for the perfect cut, so to speak. Solingen-based companies are world leaders in the production of knives, blades or scissors, and the bulk of the German cutlery and silverware industry was, and still is, based in the tranquil town in the Bergisches Land. Josef Bohle also wanted to try his luck here as an entrepreneur. He set up a small corner in the workshop of his brother-in-law and started to produce cutting wheels. His first customers included manufacturers of pocket knives that also incorporated glass cutting wheels back then.

Optimised tradition

But Josef Bohle soon discovered a new customer group: glaziers, because it was still a difficult task to cut and break glass back then. It is common to score and break the glass in less costly processing operations. Glaziers turn to diamonds for high-quality products, but they are very expensive and craftsmen need to have a great deal of skill: they need to guide the valuable tool along the glass according to the geometry of the cut. ” My grandfather recognised that this could be improved,” explains Ulrich Bohle. Josef Bohle

therefore produced a cutting wheel made of high-alloy steel, ground it, fitted it into a wooden shaft and presented it to glaziers. They were convinced straightaway. Josef and his son, August, who had now entered his father‘s business, subsequently improved the tool. They called it Silberschnitt® and officially registered it as a trademark in 1936.

Better than gold

This laid the foundations for a bright future for the family business: Josef and August Bohle continued to develop their flagship product. For example, increasing the number of cutting wheels to six, mounted in a rotatable rosette – if one is blunt, the glazier still has five more in reserve. Bohle began to produce cutting wheels made of hard metal after 1945 and production increased dramatically. The Silberschnitt® became a bestseller nationally and internationally – despite its name that was supposedly unpronounceable outside of Germany. ”Silber-Snitt“ – customers soon got used to the name. ”Sometimes my father was even addressed as ’Mr Silberschnitt’,” recalls Ulrich Bohle. The success soon attracted copycat products – without success: ”Goldschnitt“, a competitor‘s glass cutter, soon disappeared from the market again.

From a metal wheel manufacturer to a mechanical engineering company

The family business had now moved from Solingen to neighbouring Haan – and in 1972 Bohle began to grind and assemble steel wheels by machine instead of by hand. ”Mechanical production enabled mass production of the highest quality,” states Ulrich Bohle, who took over the management of the family business with his brother, Norbert, at this time. The production thus soared to 4.2 million mechanically produced wheels per year – a development that touched on issues of organisational efficiency: ”You

cannot purchase production systems to make small steel wheels,” confirms the qualified mechanical engineer, Ulrich Bohle, the Managing Director responsible for technical processes. ”When we automated our production, we inevitably became a mechanical engineering company.“

Popular all over the world

Although glaziers in Germany and other Western industrial nations now order their ”made-to-measure” goods from the factory, the legendary 100.0 model – named after the order number – is still the top-selling product at Bohle, 80 years after registering the Silberschnitt® trademark, and is delivered all over the world, from Poland and Turkey to the Middle and Far East as well as Mexico.

”The Silberschnitt® is still a great product,” states Ulrich Bohle, who retired from the operational side of the business in 2006 and continues as an adviser on the Supervisory Board of the family business, ”but you have to change with the times and ensure the future of the company.”

This means the ongoing development of Silberschnitt® 2.0, moving away from a hand-operated product to a machine used for industrial cutting technology – with laser processing and micro-structures, which significantly improve the cutting, integrated into fully automated systems. ”There will be many developments,” states Ulrich Bohle, ”but one will remain – the desire for a clean edge.“

Gespräch der Generationen: "Immer das Ohr am Kunden"

You are at the helm of a very successful family company: What is the secret of your success?

Arne Klöfkorn: It may sound stupid but we realised at an early stage at Bohle that product developments should not be an end in themselves, they need to be closely related to customers‘ requirements. We have always had a good sense of what the market wants and listened carefully to the customer. We are trying to retain this comparatively simple formula for success, especially now at a time of globalisation.

This is much easier than before thanks to digital resources …

Ulrich Bohle: Perhaps from a technical perspective. On the other hand, it is also more difficult to meet customers‘ increasing demands due to the greater transparency. Competition is also an incentive. There is a risk that you drift off without competition. You need to be openminded and invest with courage and a sense of proportion.

Bohle recently introduced a digital shower configurator into its product range. Is this your answer to a networked future?

Arne Klöfkorn: Our latest answer – but not the only one or even the first one. We have been active on the Internet since the end of the 1990s, including the web shop. Our online presence has continuously developed since then – the shower configurator is therefore just another step in our digital transformation.

How important is digitalisation for a medium-sized company that is deeply rooted in the trade and craft sector.

Thorsten Böllinghaus: It is very important for us. The trade and craft sector is now much more Internet-savvy than a few years ago. Trends from the private sector, where a lot is now done online, are now also being transferred to the business sector. We are responding to this, for example with our online shop and the new shower configurator mentioned above. Ulrich Bohle: We already became involved in digitalisation early on during my time: the first computer was purchased at Bohle at the end of the 1970s!

Why?

Norbert Bohle: We had previously sold our products mainly through distributors. Our customer base grew rapidly when we also started to deliver directly to commercial end users at the end of the 1970s. This flood of data could no longer be managed in the conventional manner.

Mr Bohle, you always used to deal with technical matters as well as many other things as Chairman of the Board. Why do you now need a separate Chief Technology Officer?

Ulrich Bohle: Bohle has always been a technology-driven company: We have always experimented with new materials and cooperated with scientific institutes, such as the Fraunhofer Institute. Our high product quality is the result of our modern, highly automated production. That‘s why a Chief Technology Officer is vital – especially as our COO, my son-in-law Arne, is a lawyer.

Arne Klöfkorn: I am responsible for sales-related matters and Thorsten Böllinghaus and I look after general matters – for instance the corporate culture.

What is important to you in this area?

Arne Klöfkorn: Employees who try to improve every day.

Thorsten Böllinghaus: That we deal with errors in a positive manner. That we create an environment for innovation and focus on the needs of our customers.

Ulrich Bohle: That the management is aware of all employees‘ concerns – even with 300 colleagues. This contact is important – because a corporate culture is represented primarily by people – especially the management team, who need to exemplify the values, such as quality, sustainability and adaptability.

Arne Klöfkorn: Adaptability is what sets medium-sized companies apart from others because the rate of change has increased enormously, even in our industry – and the pace is accelerating.

How do you withstand the pressure?

Arne Klöfkorn: Our employees play a crucial role – they need to be well trained and have the right attitude. We try to nurture our own young talent. This works well even though it is difficult as a medium-sized company to be perceived as an attractive employer.

How do you attract the attention of good employees?

Arne Klöfkorn: We provide local sponsoring and support schools in the area. We are able to use this network to attract the attention of school students and get them excited about a job with entrepreneurial spirit.

Entrepreneurial spirit – what do you mean by this?

Ulrich Bohle: A good entrepreneur always has the need for creative freedom. They want to create and improve values. These were also the driving force behind our founder Josef Bohle, who took a bold step to become selfemployed, especially in times of high inflation. Of course, entrepreneurs always have the desire to seek a better economic future. The responsibility for employees, customers, suppliers and shareholders was even more important for my grandfather and my father.

Have you ever considered selling the company?

Norbert Bohle: Never.

Ulrich Bohle: On the contrary – we were always encouraged to think about the company when we were young. The family and company are not just united under one roof in a physical sense.

Was it a mandatory provision to have a family member at the helm of the company?

Ulrich Bohle: That is not our aim anymore. This automatic approach would not be good for Bohle. Decisions are made on qualification, not family status. We have already had a few external managers on the Management Board and still do. It‘s all the nicer that we have a family member on the Board again in the form of my son-in-law, who is ready for this challenge and is looking forward to it.

Mr Klöfkorn, how difficult were your first steps in the family company?

Arne Klöfkorn: Initially I was responsible for the Human Resources Department and then gradually I passed through the individual business areas. At the start it wasn‘t clear if I would ever become a member of the Board or even fit in at Bohle. I would have had the option to walk away again.

Having your father-in-law as Chairman of the Supervisory Board – this surely doesn‘t make life easy ...

Arne Klöfkorn: Of course, there have always been issues where we have not been that happy with each other. But we keep our business and private issues strictly separate.

Norbert Bohle: There has never been this distinction for me; joining the company was a matter of course. That was in 1957, I was 21 years old at the time. Since the aim was for me to look after the international business at a later date, I initially worked with partner companies in Brussels and London to learn English and French.

Ulrich Bohle: I didn‘t want to join the family company straightaway and studied maths and physics. But at some point you have to decide. So I moved to RWTH Aachen University and switched to mechanical engineering.

… So that you could then fall into a well-feathered nest?

Ulrich Bohle: Not at all. I quickly realised that I would not be satisfied with the company as it stood then.

How did you and your brother arrange things?

Ulrich Bohle: I was responsible for technology and my brother was responsible for sales. My father‘s stroke – as hard as it may sound – was also an opportunity for me personally to take the shaping of the company into my own hands at an early stage and accept it as a challenge.

Today you advise the Supervisory Board. How difficult was it for you to let go of the operational side of the business?

Norbert Bohle: Not very hard. I knew that my duties were in good hands and so I could reassuringly switch to the Supervisory Board at 65 years old.

Ulrich Bohle: We have given our shares to our children. We still hold one percent – so that we can still be invited to Supervisory Board meetings (he laughs).

Norbert Bohle: The Management Board sends us documents on a regular basis so we are always kept up to date.

Ulrich Bohle: Yes, this keeps you fit. Nevertheless, I am glad to be able to devote myself to other interests. I regularly attend philosophy seminars in Frankfurt.

How have you managed to hold onto the money for 100 years?

Ulrich Bohle: By not spending money unnecessarily. An excessive lifestyle was always alien to us and personal wealth was never our goal.

Arne Klöfkorn: We are not tight-fisted, but we are careful with money. When we are on business trips, people choose the class of hotel that they would stay in privately.

What is luxury in your opinion?

Norbert Bohle: I certainly don‘t drive a Ferrari. I go hiking when I want to relax – or I cut the grass.

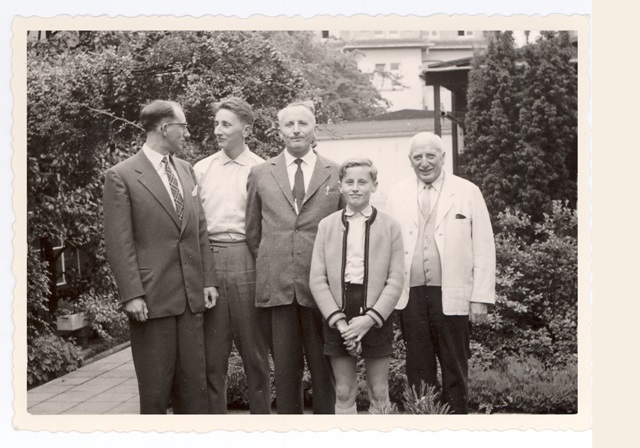

Ulrich Bohle, 76, grandson of the company founder Josef Bohle and brother of Norbert Bohle, worked in the company for over 40 years, including many years as the Chairman of the Board. He still advises the Supervisory Board of the medium-sized company.

Norbert Bohle, 80, was responsible for the export department at Bohle. He moved to the Supervisory Board in 2001 and retired from there in 2013 – 56 years after he joined the family company.

Arne Klöfkorn, 44, is responsible for sales matters on the Management Board. Ulrich Bohle‘s son-in-law joined the company as Human Resources Manager in 2004.

Dr. Thorsten Böllinghaus, 42, joined Bohle in May 2016 as Chief Technology Officer. (from left)