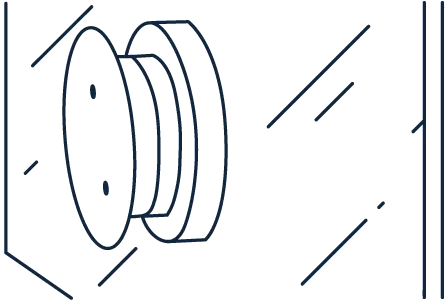

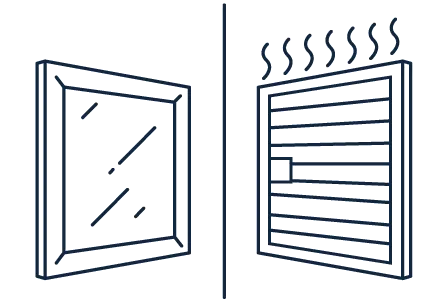

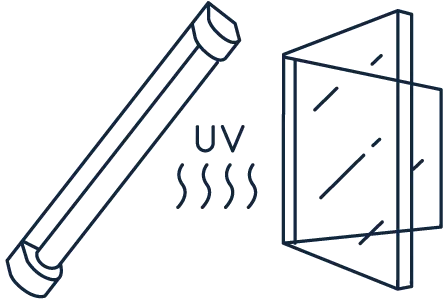

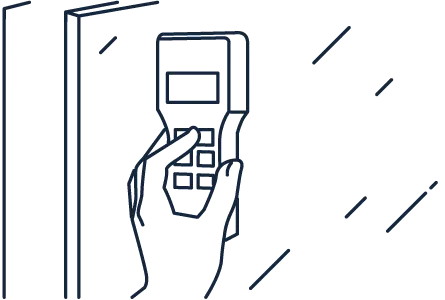

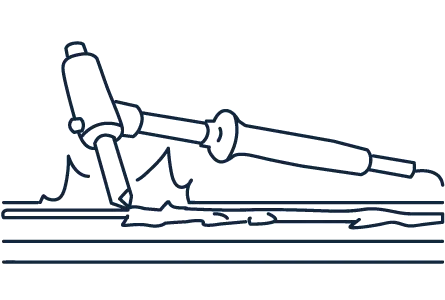

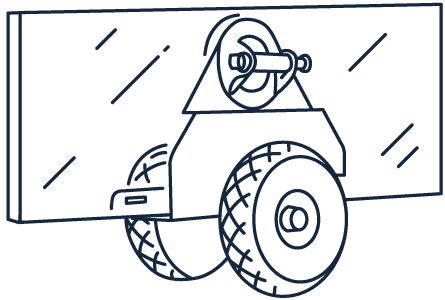

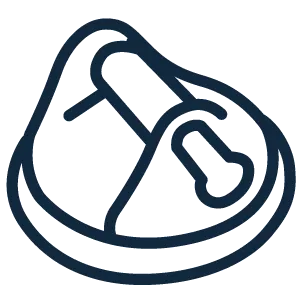

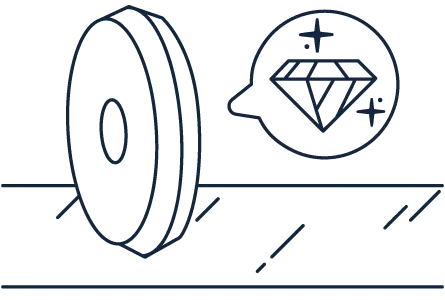

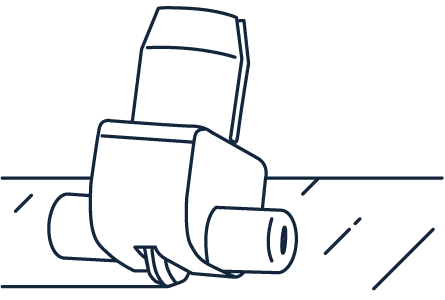

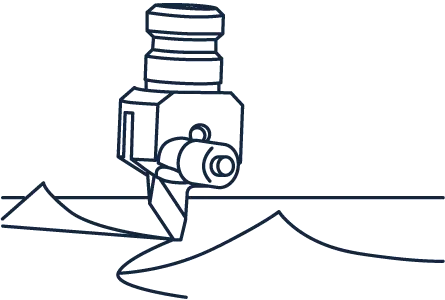

The Merlin Laser is used for the optical analysis of glass thicknesses and structures. It detects single glass, laminated glass, coatings and spaces between panes. The results are displayed as red lines and read on the sliding scale. The individual measurements are added up at the end.

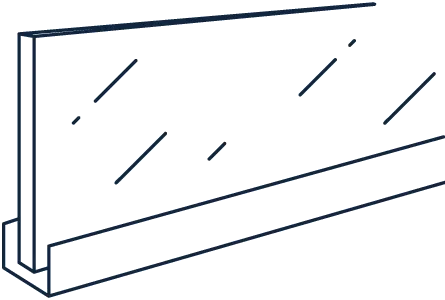

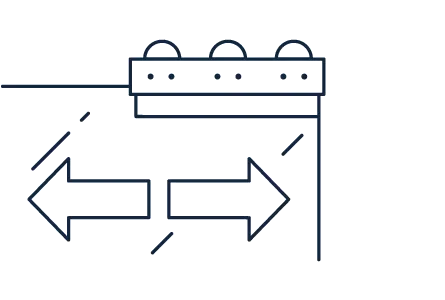

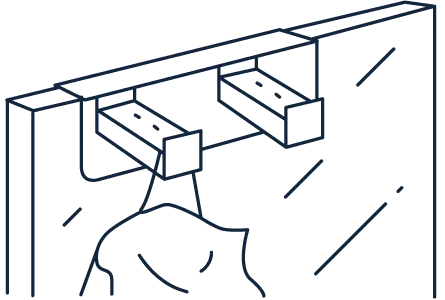

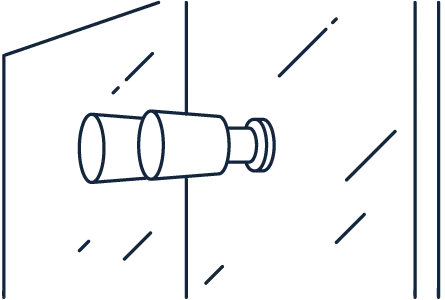

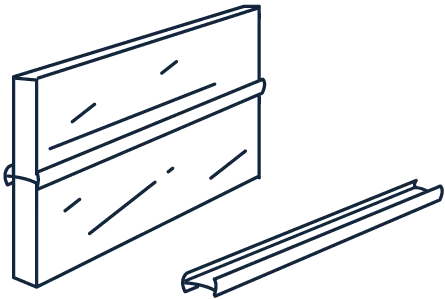

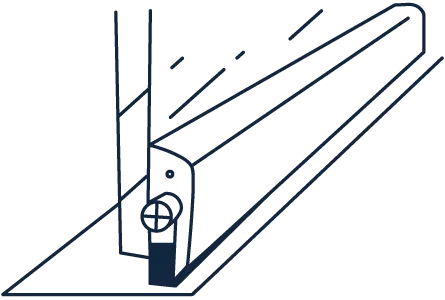

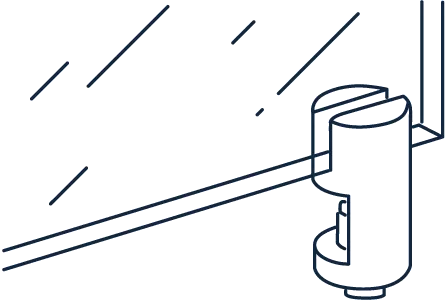

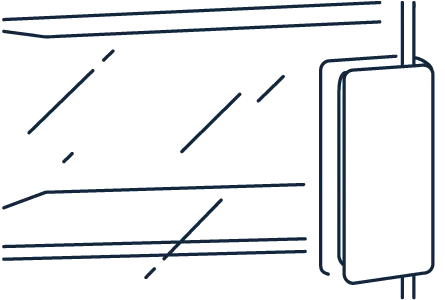

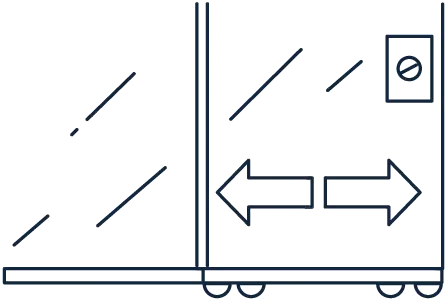

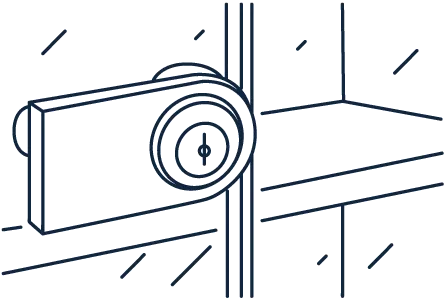

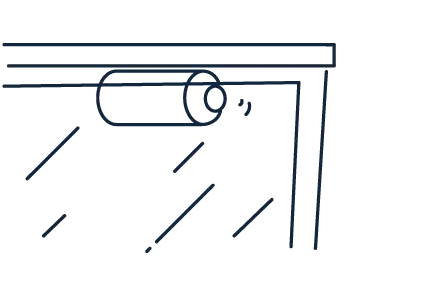

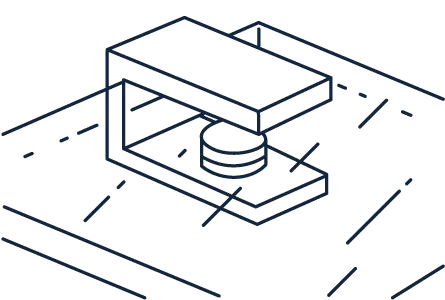

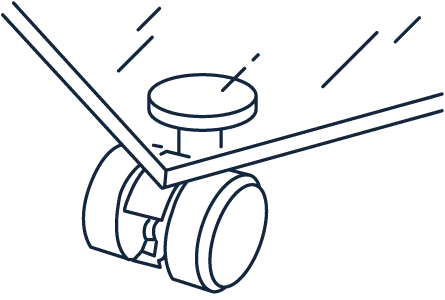

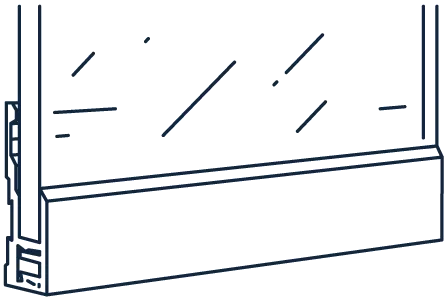

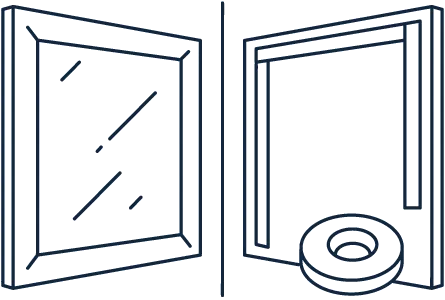

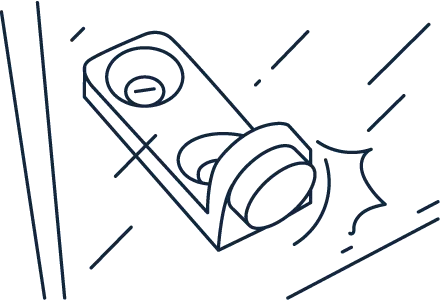

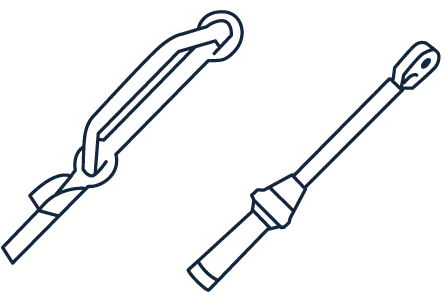

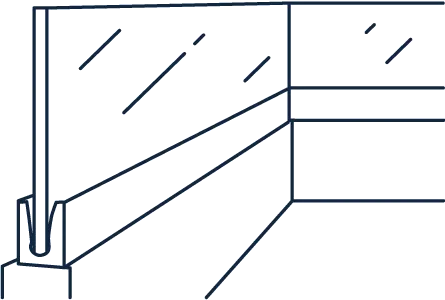

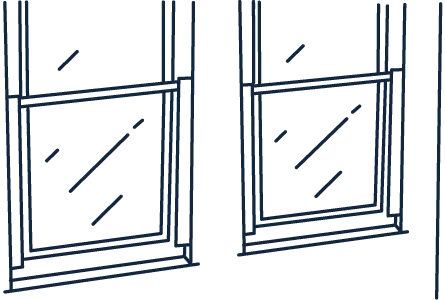

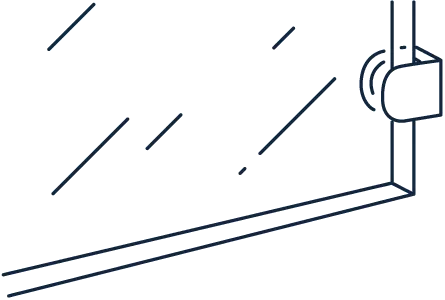

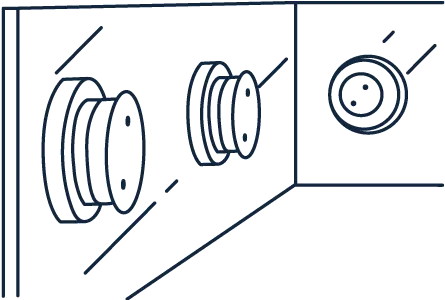

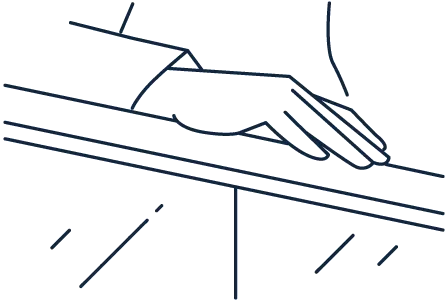

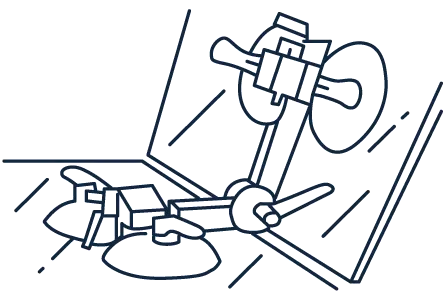

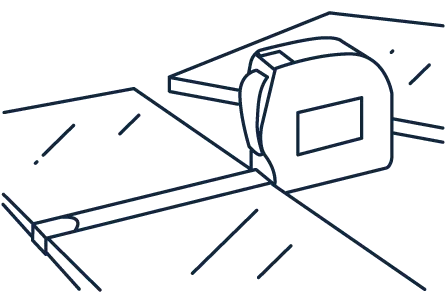

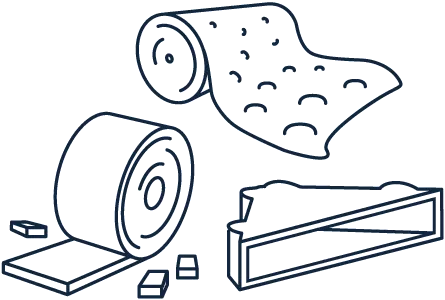

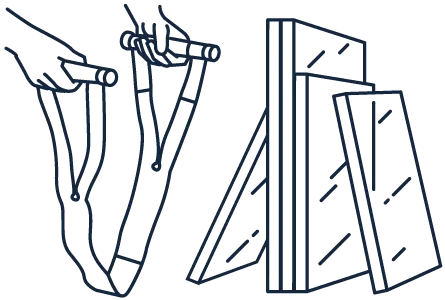

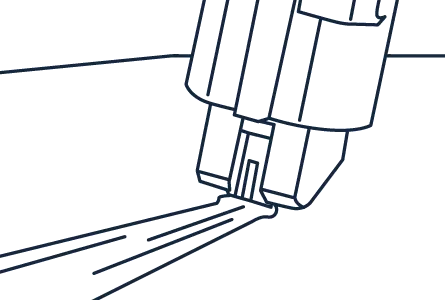

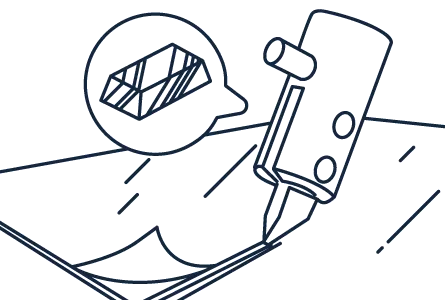

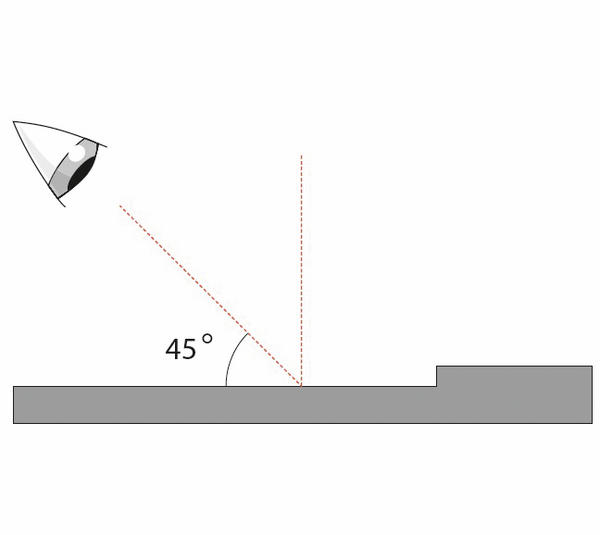

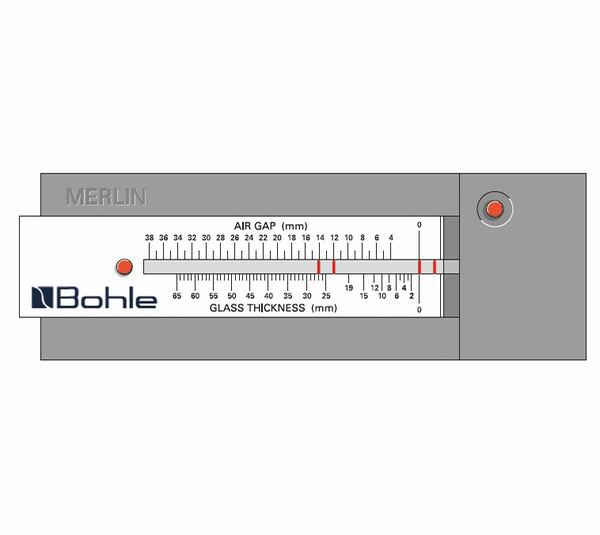

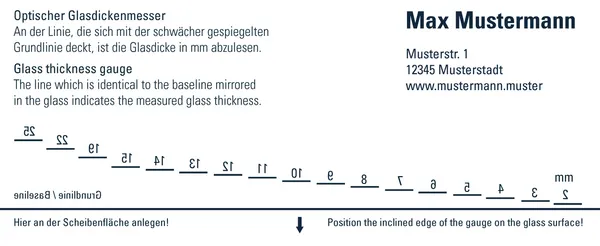

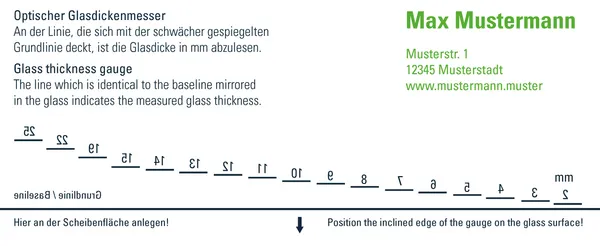

The Merlin Laser measures the thickness of individual glass panes and the space between the panes quickly and easily from just one side, without removing the glazing. It has 2 scales (for standard glass thicknesses and the space between the panes): GLASS THICKNESS scale This scale shows the thickness of single glazing, as well as almost all types of functional, insulating and multi-pane insulating glazing. It shows films for laminated safety glass, layer detection for cast resin laminate, as well as the coating side for solar and heat insulation glass. GLASS INTERPANE SPACE SCALE (SZR) This scale measures the space between the panes of insulating and multi-pane insulating glass. In conjunction with the glass thickness scale, total thicknesses can be measured quickly and easily. How to use the Merlin Laser: - Regardless of the type of glass to be measured, the Merlin Laser must be placed with its underside flat on the clean glass surface at approximately eye level. (Close to the edge seal of the glazing unit, as the space between the panes can vary depending on the air pressure and size of the pane) - Measure by pressing and holding the touch switch, then read the measurement result on the scale - The laser lines on the scale are most clearly visible when the scale is viewed at an angle of approx. 45°. Measurement example: 2 x 4 mm float glass with SZR 12 mm - Place the Merlin Laser on the clean glass surface as described above - Slide the scale to the right as far as it will go - The zero point must align with the first laser line - Now read off the glass thickness of the first pane on the lower "Glass thickness" scale. result = 4 mm. - Move the zero point of the upper scale "Space between panes (SZR)" to the 2nd laser line and read off the gap between the panes on the 3rd laser line. Result = 12 mm. - Move the zero point of the lower scale "Glass thickness" to the 3rd laser line and read off the glass thickness of the second pane at the 4th laser line. Result = 4 mm - To determine the total thickness, you must add up all the measured values. Result = total thickness 20 mm. Different types of glass can be easily determined by the number and intensity of the laser lines: - Single pane - 2 laser lines are visible - Single pane, coated - 2 laser lines are visible, the more intense of which indicates the coated glass surface (e.g. low-E or hard coating) - Insulating glazing - 4 laser lines are visible - Multi-pane insulating glazing - 6 laser lines are visible for triple glazing, for example. - Laminated safety glass/soundproof glass - 2 single panes with single film (PVB) - 3 laser lines are visible, of which 1 paler line indicates the film. - 2 single panes with multiple PVB film - 4 laser lines are visible, of which 2 paler lines indicate the layer. - 2 single panes with cast resin - 4 laser lines are visible, of which 2 paler lines indicate the layer - More than 2 panes with different film and layer thicknesses - the Merlin laser displays the individual glass thicknesses, film and cast resin layers depending on the structure of the pane laminate

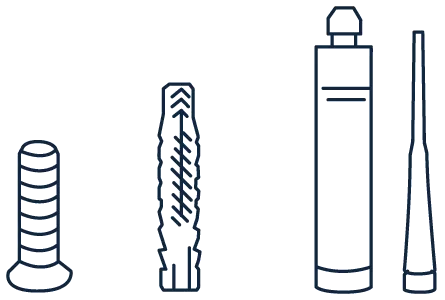

Application note:

Observe the enclosed operating instructions.