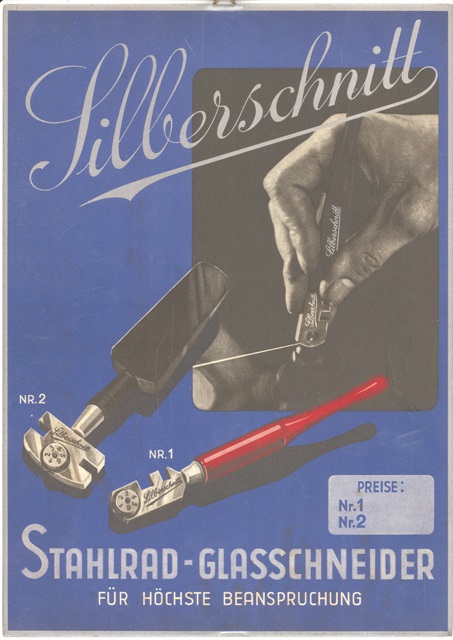

Brand talk: Silberschnitt

Whether it‘s Fulton for umbrellas, Kleenex for tissues or Sellotape for adhesive tape: every company dreams of brands that become synonymous with their product range. Bohle has achieved this: the Silberschnitt®, a pocketsized glass cutter, is the number one for glass processors around the world – and has been an indispensable basis for the success of the medium-sized company from North Rhine-Westphalia for 80 years.

First she threads the cutting wheel onto wire, then guides it carefully over a test piece: Silvia Manjinder meticulously checks every cutting wheel before a Silberschnitt® glass cutter leaves the production hall and is delivered, for instance, to the United Arab Emirates or Argentina. The 48-year-old has been working in quality control at Bohle for 19 years. Her credo: anything that squeaks and wobbles will fly out. ”It needs to have a uniform hum and whirr, feel good in your fingertips and not judder or run unevenly,” states Silvia Manjinder.

Drive for entrepreneurial freedom

Looking good, in the eyes of Silvia Manjinder, means have a silvery shine – and she explains how the tool, synonymous with the core expertise of her employer, got its name: Silberschnitt®. It was named after the shiny silver fissure created within the glass when the high-quality cutting wheel is guided over the glass with the appropriate pressure and the necessary stress, which allows it to be broken precisely along the desired line.

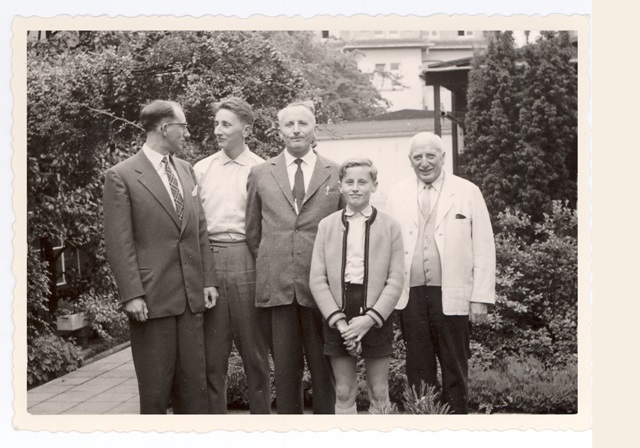

Glass cutters have been included in the product range of the medium-sized company for over 80 years and the classic 100.0 is the bestselling product at Bohle to date. The Silberschnitt® brand is a complete product range today that includes glass cutters made of steel and hard metal with an oil reservoir integrated into the handle, glazing tools, angle holders and templates. The Silberschnitt®, which is much more than merely a tool, is available in many variants. For in a similar manner to Kleenex for tissues or Sellotape for adhesive tape, the Silberschnitt® is generally regarded as being synonymous with glass cutters in many countries around the world. „The Silberschnitt® is the very root of our family business,” states Ulrich Bohle, grandson of the company founder, Josef Bohle. “Without it we wouldn‘t be where we are today.“

The tool shaped the company history at an early stage: In the wake of the economic crisis at that time, locksmith Josef Bohle left his native Westphalia and moved to Solingen, Germany‘s capital for the perfect cut, so to speak. Solingen-based companies are world leaders in the production of knives, blades or scissors, and the bulk of the German cutlery and silverware industry was, and still is, based in the tranquil town in the Bergisches Land. Josef Bohle also wanted to try his luck here as an entrepreneur. He set up a small corner in the workshop of his brother-in-law and started to produce cutting wheels. His first customers included manufacturers of pocket knives that also incorporated glass cutting wheels back then.

Optimised tradition

But Josef Bohle soon discovered a new customer group: glaziers, because it was still a difficult task to cut and break glass back then. It is common to score and break the glass in less costly processing operations. Glaziers turn to diamonds for high-quality products, but they are very expensive and craftsmen need to have a great deal of skill: they need to guide the valuable tool along the glass according to the geometry of the cut. ” My grandfather recognised that this could be improved,” explains Ulrich Bohle. Josef Bohle

therefore produced a cutting wheel made of high-alloy steel, ground it, fitted it into a wooden shaft and presented it to glaziers. They were convinced straightaway. Josef and his son, August, who had now entered his father‘s business, subsequently improved the tool. They called it Silberschnitt® and officially registered it as a trademark in 1936.

Better than gold

This laid the foundations for a bright future for the family business: Josef and August Bohle continued to develop their flagship product. For example, increasing the number of cutting wheels to six, mounted in a rotatable rosette – if one is blunt, the glazier still has five more in reserve. Bohle began to produce cutting wheels made of hard metal after 1945 and production increased dramatically. The Silberschnitt® became a bestseller nationally and internationally – despite its name that was supposedly unpronounceable outside of Germany. ”Silber-Snitt“ – customers soon got used to the name. ”Sometimes my father was even addressed as ’Mr Silberschnitt’,” recalls Ulrich Bohle. The success soon attracted copycat products – without success: ”Goldschnitt“, a competitor‘s glass cutter, soon disappeared from the market again.

From a metal wheel manufacturer to a mechanical engineering company

The family business had now moved from Solingen to neighbouring Haan – and in 1972 Bohle began to grind and assemble steel wheels by machine instead of by hand. ”Mechanical production enabled mass production of the highest quality,” states Ulrich Bohle, who took over the management of the family business with his brother, Norbert, at this time. The production thus soared to 4.2 million mechanically produced wheels per year – a development that touched on issues of organisational efficiency: ”You

cannot purchase production systems to make small steel wheels,” confirms the qualified mechanical engineer, Ulrich Bohle, the Managing Director responsible for technical processes. ”When we automated our production, we inevitably became a mechanical engineering company.“

Popular all over the world

Although glaziers in Germany and other Western industrial nations now order their ”made-to-measure” goods from the factory, the legendary 100.0 model – named after the order number – is still the top-selling product at Bohle, 80 years after registering the Silberschnitt® trademark, and is delivered all over the world, from Poland and Turkey to the Middle and Far East as well as Mexico.

”The Silberschnitt® is still a great product,” states Ulrich Bohle, who retired from the operational side of the business in 2006 and continues as an adviser on the Supervisory Board of the family business, ”but you have to change with the times and ensure the future of the company.”

This means the ongoing development of Silberschnitt® 2.0, moving away from a hand-operated product to a machine used for industrial cutting technology – with laser processing and micro-structures, which significantly improve the cutting, integrated into fully automated systems. ”There will be many developments,” states Ulrich Bohle, ”but one will remain – the desire for a clean edge.“