In a master training session

Listen, bone up, sweat: As supporting member of the Federal Glazier´s Guild, Bohle regularly offers the opportunity to Master students to deepen their theoretical and practical knowledge on site. For example, in a seminar about mounting sliding door systems. A glimpse behind the scenes.

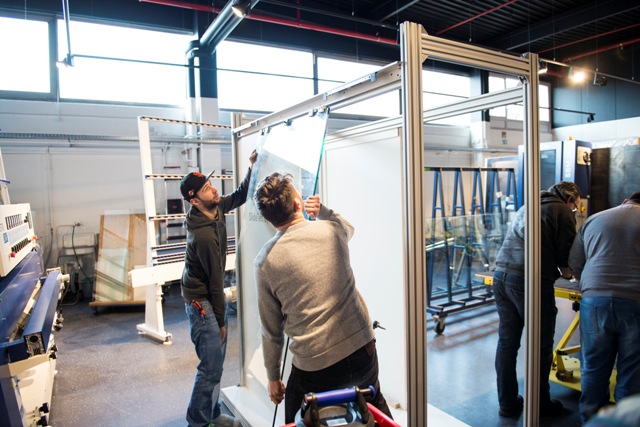

Fabian S. and Jasim-Osman C. high-five each other. The Master Glaziers to-be have just mounted SlideTec optima 50, a Bohle sliding door system with damper, in only 30 minutes. The two assistants from Bonn and Herford seem to have mastered the practical part of the “Mounting Sliding Door Systems” seminar, taking part in the Visitor Centre at Bohle AG in Haan, with flying colours. However, their satisfaction quickly fades. The fact that the clamping adaptors for the cover of the system have been mounted in the wrong place has not escaped the critical eye of David Menzel, Technical Customer Consultant for the Hardware Division at Bohle. “Please mount this again”, Menzel says. The two are feeling compunctious. In their opinion, this mistake is excusable. “A customer will definitely place a complaint”, Menzel says. Therefore, the clamps must be removed again as in this position they open the sliding door so far that the damper is not able to guide the door into its final position. “The students must get used to working more accurately in precisely those details”, Menzel explains.

Six seminars per year

Nine students of the Technical College for Glass in Rheinbach have signed up for the seminar at the end of January – one of many forming part of their master training. Mounting sliding door systems is part of the compulsory programme, “a complex matter”, the participants say. Over the course of a year, master students from all over North Rhine-Westphalia attend the lessons of the Technical College for Glass in Rheinbach on Fridays and Saturdays – apart from their regular jobs in different companies. After passing the master exam, most of the participants are planning to work self-employed or take over the family business.

Bohle is a supporting member of the Federal Glazier´s Guild. Under the name of Bohle Glass Academy, the company has been offering seminars incorporated into the training of the future masters for more than ten years. For good reason: Glass hardware is an mportant part of the product portfolio at Bohle, with rising trend. Only in 2016, the turnover of this division increased by 20% when compared to the previous year. “Our commitment ensures that the young generation acquires the required expertise ahead of time”, seminar instructor Menzel points out.

The 30-year-old Master Glazier from Essen gives lectures on sliding door systems six times a year. After successfully completing his training and master exams, he moved from the tool case to the computer. Menzel has been working for Bohle for almost five years now and has already trained the employees of the Bohle subsidiaries in England, Sweden and China.

Theory and practice in perfect harmony

Today back at the Bohle headquarters in Haan: Before the practical part, Menzel talks to participants on theoretical issues over a cup of coffee. The hardware specialist informs participants about the requirements and the different versions of sliding door systems, shares some tips and tricks for measuring and assembly, speaks about the latest trends in automatic applications and about accessibility. Participants already know some the topics but most is new to them. Then, the future Master Glaziers take out their smartphones, not to take selfies, however – but to calculate the glass dimensions, position of drill holes, profile lengths, clearance dimensions and the handle height of a sliding door system. Menzel provides the framework conditions – product, mounting type, inside width. After 20 minutes, the participants have finished – Master Glazier Menzel reviews and corrects.

“A lot learned”

Shortly after, Maximilian S., who, apart from doing the master training, works in the family business in Bedburg, and Simon R. from Grevenbroich give the ultimate discipline a try: mounting a sliding door. Their mission: ceiling mounting of a Bohle SlideTec optima 150 synchronous converter which enables opening and closing two glass doors with a weight of up to 150 kg in opposite directions via deflection rollers. 90 minutes later, almost everything looks as it should be. Only the doors do not close flush. “The top carriages can be height adjusted by 3.5 mm”, instructor Menzel explains. “On site such an assembly might take you a whole day”, master student Simon R. says. “Here we have laboratory conditions. I did not know the system though. Therefore, here I have learned a lot today.”