01.09.2022 - The cutting technology specialist from Haan near Düsseldorf will present its new range of high-performance cutting fluids for industrial glass cutting at glasstec. For many years now, the well-known system provider has been selling cutting fluids for industrial glass cutting from a renowned chemical company as part of a cooperation in addition to its precision cutting wheels, wheel carriers and cutting heads. With the new Silberschnitt® cutting fluids, Bohle AG is now launching a completely new product family on the market, which has been even better matched to the other cutting technology system components from Bohle. Perfectly matched elements are important for the quality of glass cutting, especially in series production. Over several years, application engineers and product developers from Bohle have therefore incorporated their experience into the new products in order to achieve even better results in machine cutting applications. This rounds off the company's own cutting technology range with a now fully integrated solution, enabling it to provide even more sound process advice. In addition to the improved cutting performance, Bohle’s developers were also concerned about sustainability and product safety. Thus, only high-purity synthetic lubricants are used, which have a significantly improved environmental balance than conventional mineral oil products and are harmless to health. The high quality of the new Silberschnitt® product family is also reflected in the fact that most of the world's major glass manufacturers have already qualified the new cutting fluids for their production. The new range includes both evaporative and wash-off variants.

In addition to the improved cutting performance, Bohle’s developers were also concerned about sustainability and product safety. Thus, only high-purity synthetic lubricants are used, which have a significantly improved environmental balance than conventional mineral oil products and are harmless to health. The high quality of the new Silberschnitt® product family is also reflected in the fact that most of the world's major glass manufacturers have already qualified the new cutting fluids for their production. The new range includes both evaporative and wash-off variants.

Cutting fluid as a quality factor

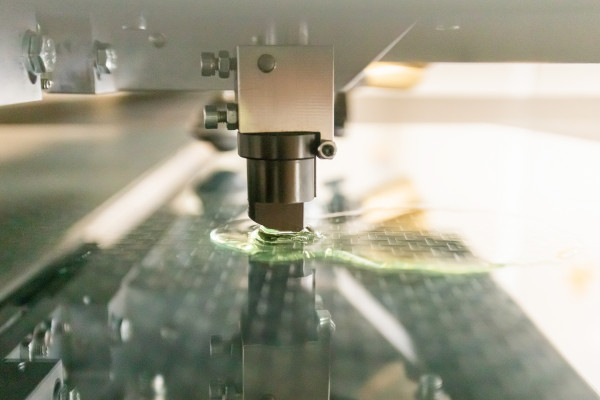

In industrial glass cutting, it is the detail that counts. By using the high-quality Silberschnitt® cutting fluids, the cutting wheel used is already lubricated in the wheel holder and thus the friction to the other system components is minimised. This significantly improves the rolling behaviour on the glass. The result is a longer service life for the wheels and therefore less machine downtime. More important, however, is the improved penetration of the cutting wheel into the glass surface due to the modern cutting fluids and the physical-chemical support during the cut opening. This makes processing more flexible, reduces the required cutting forces and significantly increases the edge quality. Among other things, the formation of splinters and micro-cracks, which can negatively influence edge strength, is significantly reduced. In addition, the cutting fluid binds the glass dust created during the cutting process which can be evaporated or washed off without leaving any residue. As a result, users avoid consequential damage in the downstream process steps. A first-class cutting result ultimately guarantees a stable production process and saves costs.

The new range of Silberschnitt® cutting fluids serves the different needs of customers with five variants so far. In addition to three evaporation times, Bohle AG offers two further washable cutting fluids which differ in their viscosity. All five variants are available in 5, 30 and 200 litre containers.