Transparent UV Bonding

Bonding materials in general is state-of-the-art in advanced furniture construction and shop fitting. It´s in the execution, however, where the wheat is separated from the chaff. Optimum workspace design, careful preparation, the right selection of materials and, last but not least, the professional handling of the entire process make the difference. Bohle offers you everything you need for a high quality bond: As well as 30 years of glass bonding experience, Bohle also has the world´s largest product range for this technology which delivers crystal clear benefits for your business: for example, a wide array of design possibilities, short processing times and small investments in equipment. Open up new fields of business and broaden your offer. Here you will learn step by step how to achieve a high quality UV bond.

Step 1 - Cleaning and Surface Pre-treatment

An optimum bonding result can only be achieved if the surface is absolutely clean. Therefore, thorough cleaning of the material before bonding is of crucial importance. All bonding surfaces must be clean, dry and free of grease. The cleaning agent used must not leave any residues and must not form separation layers on the bonding surfaces.

Standard cleaning of the bonding surfaces is not enough for some materials in order to achieve a good adhesion of the adhesive. If a pre-treatment is required, choosing the suitable system is essential.

Step 2 - Fixing and Positioning

The adhesive polymerises while curing and forms a network. Insufficient fixing of the bonding parts may lead to this network being damaged. This will impair the final bonding strength. The long-term stability of the bond can then no longer be guaranteed. The Bohle Verifix® fixing aids prevent vibrations, shocks or the slipping of the bonding parts and thus ensure the best possible handling.

Step 3 - UV Adhesives

The selection of the right adhesive depends on the material combination, the environmental conditions and the loads to be expected. Apart from low-viscosity adhesive with capillary action, there are also medium-viscosity, impact resistant or elastic adhesives available. Also features like moisture and yellowing resistance are now considered state-of-the-art.

At times, the use of UV curing adhesives is not possible. This may be due to the fact that the bonding materials are insufficiently translucent or the combination of the materials to be bonded and the UV adhesives can lead to chemical incompatibilities. In those instances, Bohle offers different two-component structural adhesives as suitable applications

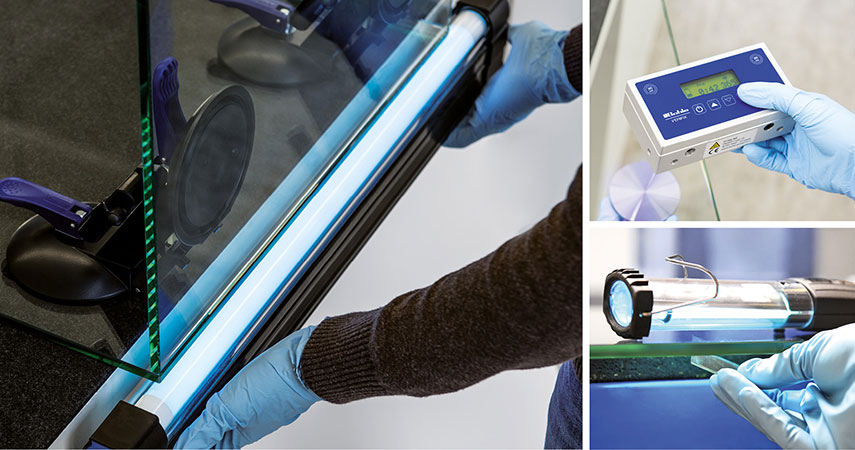

Step 4 - Curing with UV Light

Bohle offers an extensive range of UVA lamps for curing UV adhesives. Always choose your lamp according to the size/area to be bonded in order to achieve a uniform light exposure of the bonding surfaces. This avoids the accidental formation of tensions inside the bond which can lead to its failure. The lamps are therefore suited especially well for bonding metal parts or short bonding joints. For longer joints, tube lamps with the appropriate length should be used to minimise tensions. All Bohle UVA lamps are equipped with special filter screens. They must only be used with intact filter screens to avoid injuries to skin and eyes.