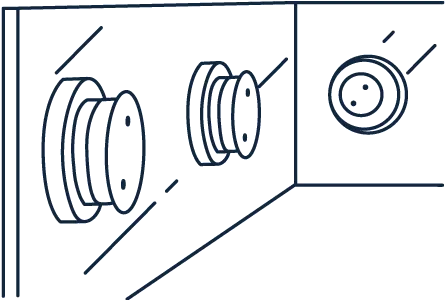

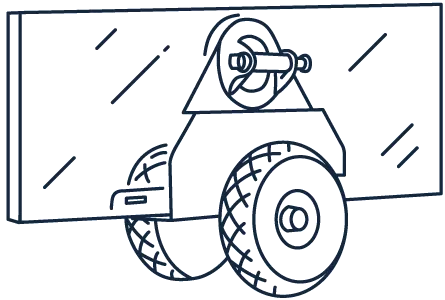

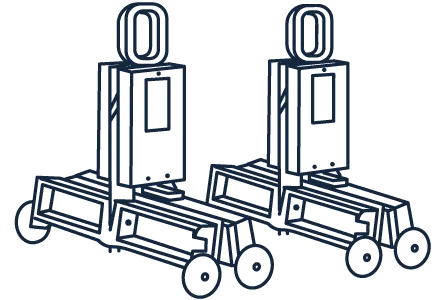

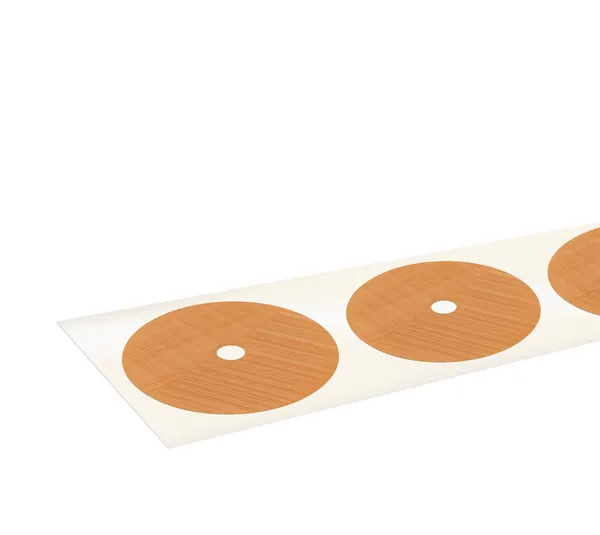

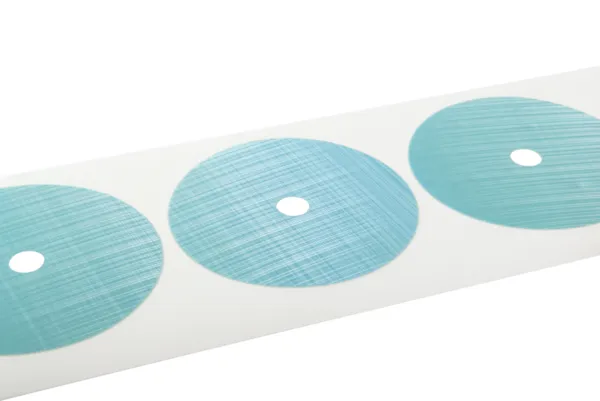

3M™ Trizact™ 268XA Aluminium Oxide (PSA) are self-adhesive polishing discs for sticking on magnetic foil or steel discs, specially developed for use on horizontal disc grinding machines for polishing surfaces and edges on glass or glass-like materials.

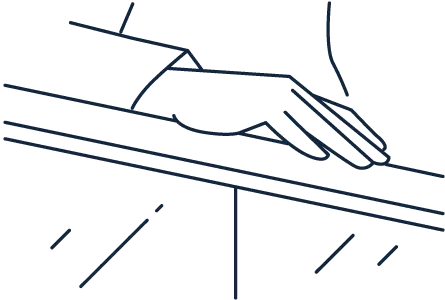

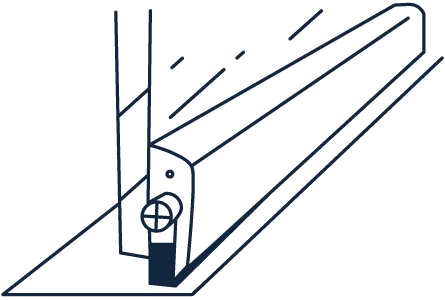

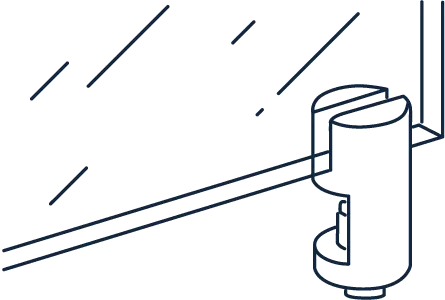

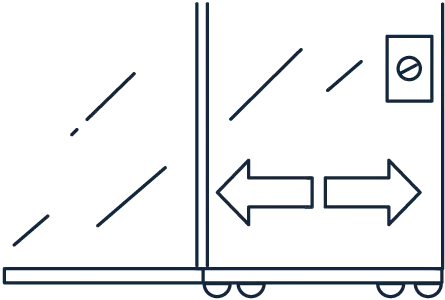

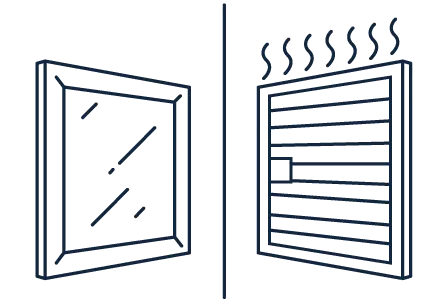

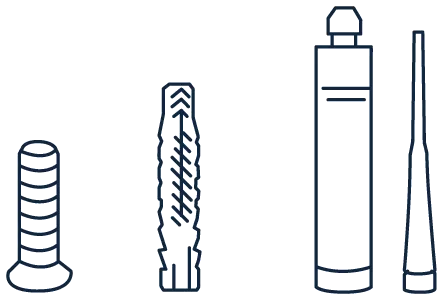

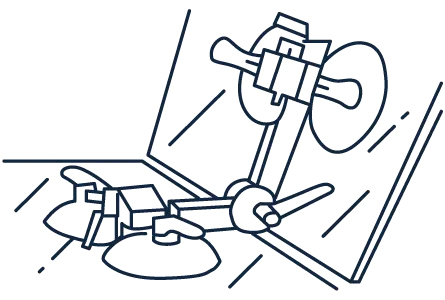

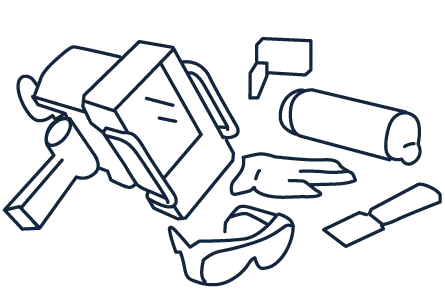

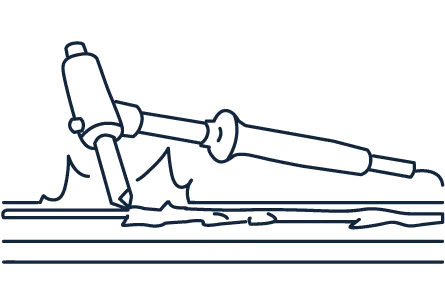

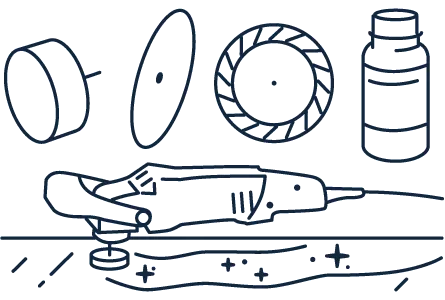

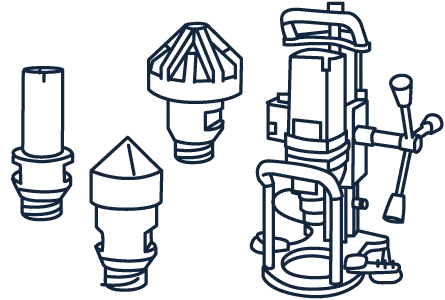

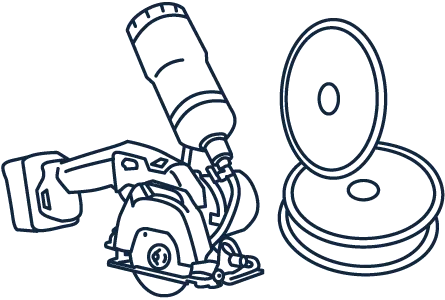

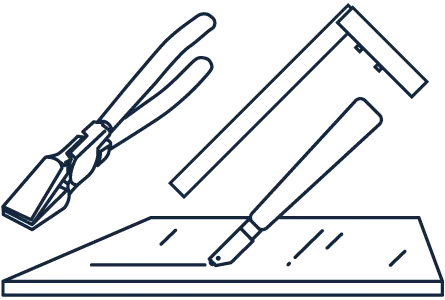

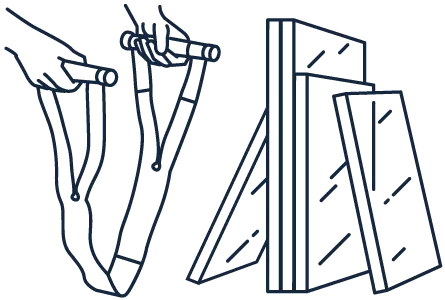

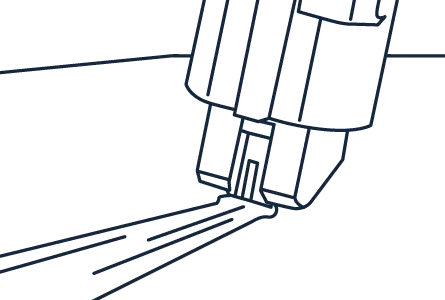

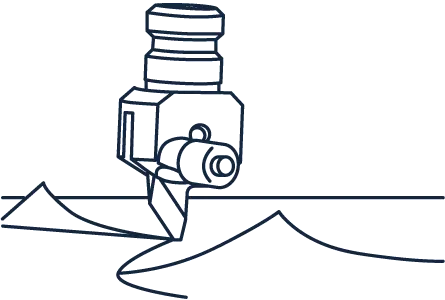

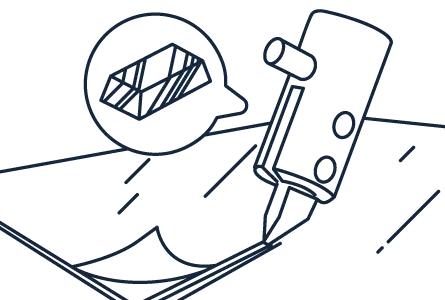

Microreplication of pyramid-shaped particles for a long service life: Trizact™ structured abrasives are based on a precisely arranged, three-dimensional structure of tiny mineral particles. During processing, new layers of abrasive particles are continuously exposed - right down to the backing. When the disc is halfway through grinding, over 85 % of the abrasive particles are still available. The result is a service life many times longer than that of conventional abrasives. 268XA discs are suitable for wet and dry applications and can be reused throughout their service life. Application instructions for glass repair: o Clean the glass disc and mark (from the back) the damage. o Carefully check the damage (nail test - the depth of the scratch is determined here) and select the abrasive. o If the scratch is deep (> 0.02 mm), use the "coarse-grained" green 3M™ Trizact™ 268XA abrasive disc (BO 5300804). After moistening the disc with a little water, grind the scratch out over a large area using an angle grinder (speed 2, 1,200 rpm). o This is followed by intermediate grinding with the next finer grit (3M™ Trizact™ 268XA sanding disc BO 5300803) at 1,200 rpm. Make sure that all grinding grooves are completely sanded out and that a slightly larger area is processed than in the first work step in order to achieve a clean transition. o The fine scratches are sanded out with the brown 3M™ Trizact™ 268XA grinding disc (BO 5300802) and corresponds to the previous work step. o This is followed by polishing (no paste required), which requires a dust-free surface. In this step, the white polishing disc 3M™ Trizact™ 568XA (BO 5300801) moistened with water is placed almost flat on the water-moistened glass surface at 1,200 rpm. As soon as the liquid has dried, the glass pane is moistened again and the process is repeated two to three times. The glass pane should then be checked (re-polish if necessary). o The final step is polishing with 3M™ 60150 polishing fluid (BO 5300806). The angle grinder is fitted with the backing pad and the polishing and cleaning velcro disc BO 5300808 is mounted and moistened. The user applies two tablespoons of 3M™ 60150 polishing fluid (BO 5300806) to the disc and polishes the glass at 1,200 rpm. After drying and moistening several times, dry polishing can then be completed. It is important to clean the disc between the individual steps and to clean it at the end. In addition, the abrasive must be deburred before use and a feed movement must be recognisable when the machine is set up

About the product series 3M™ Trizact™:

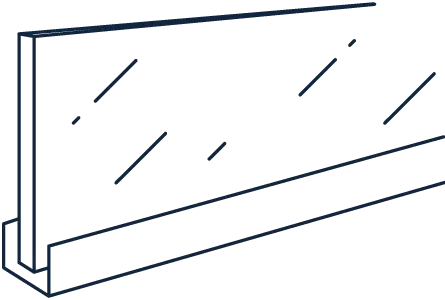

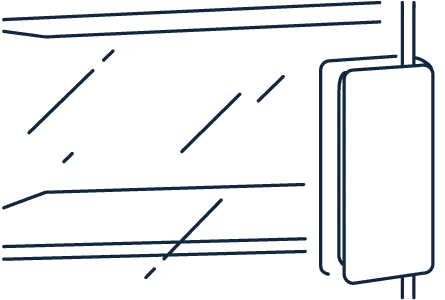

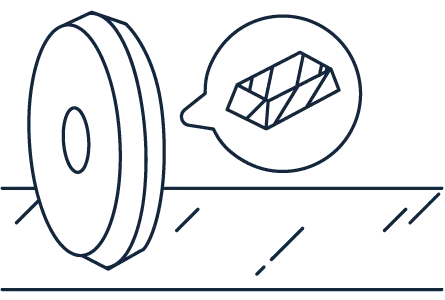

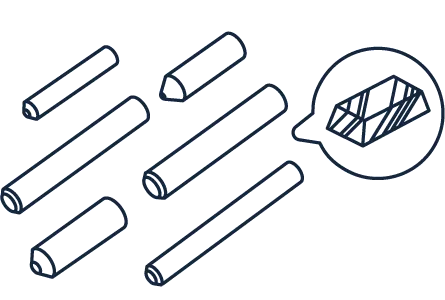

Microreplication of pyramid-shaped particles for long tool life:

Trizact™ structured abrasives are based on a precisely arranged, three-dimensional structure of tiny mineral particles. As they are worked off, new layers of abrasive particles are continuously exposed - right down to the backing. Even when the belt is half ground, over 85 % of the abrasive particles are still available. The result is a service life many times longer than that of conventional abrasives.

Application note:

Use 3M™ 268XA A 5 brown grit to grind out the finest scratches.