To be able to use the full range of Shopware 6, we recommend activating Javascript in your browser.

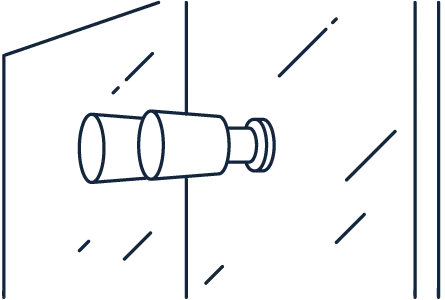

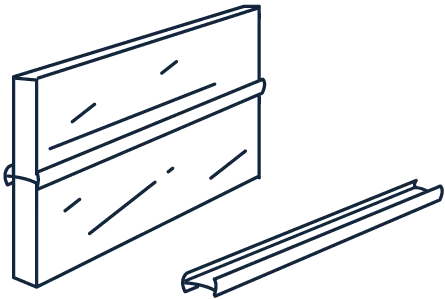

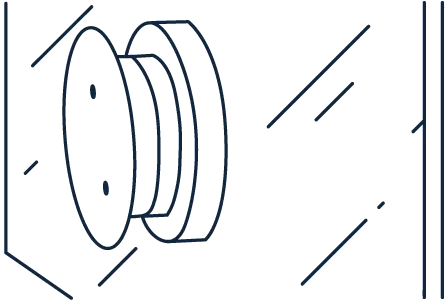

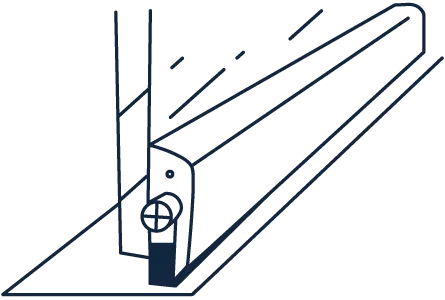

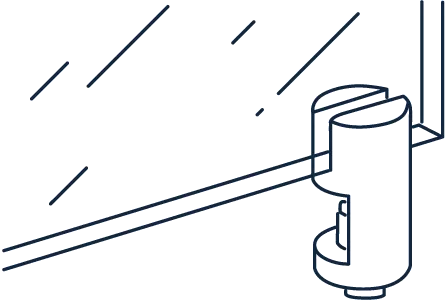

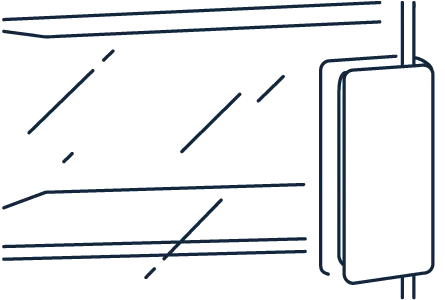

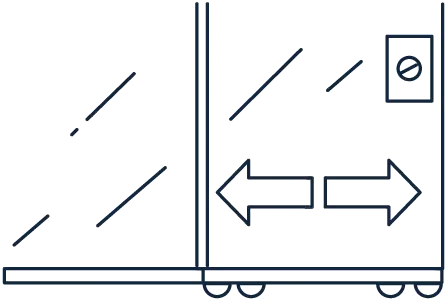

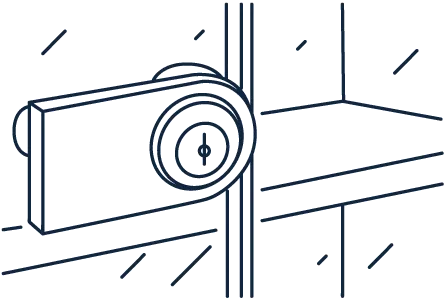

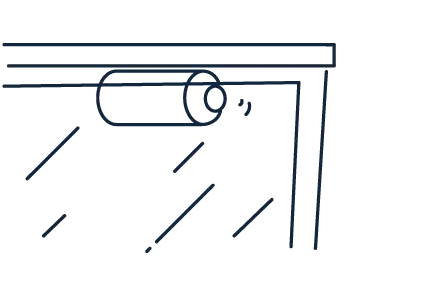

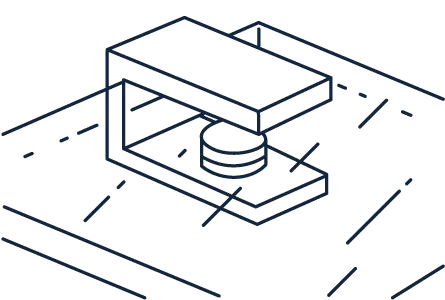

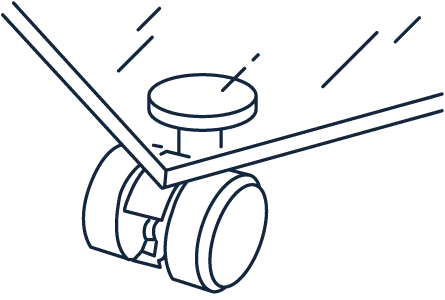

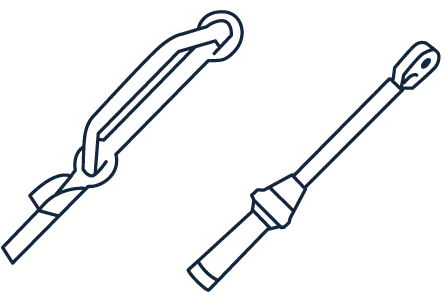

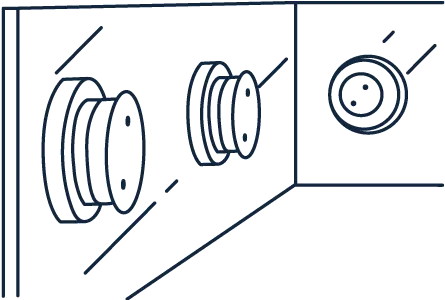

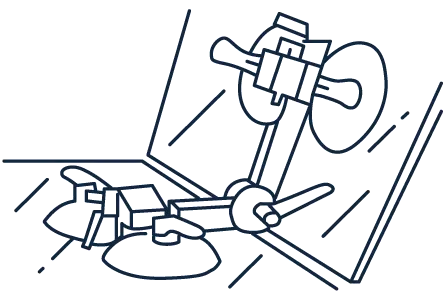

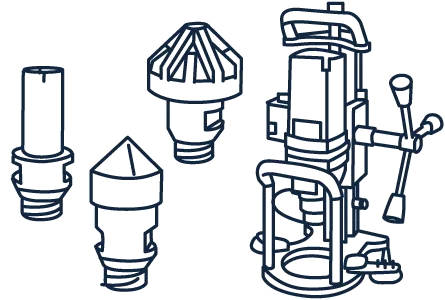

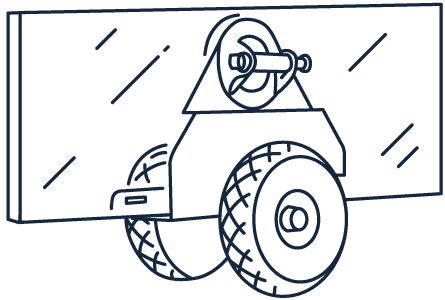

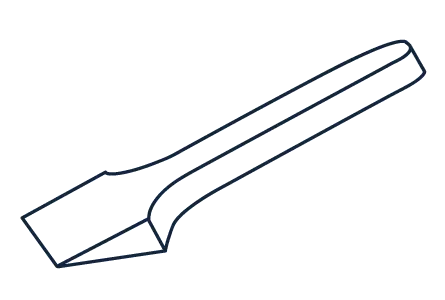

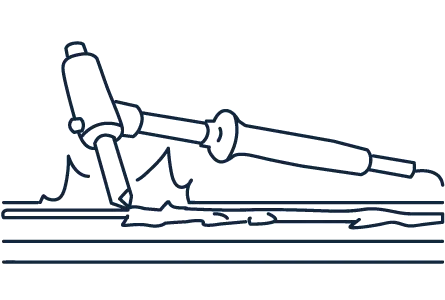

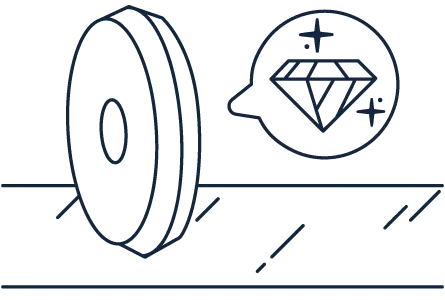

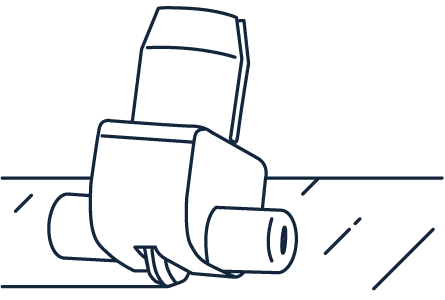

Standard diamond hollow drill

Please to see prices.

Description

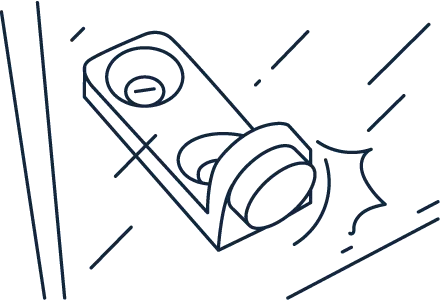

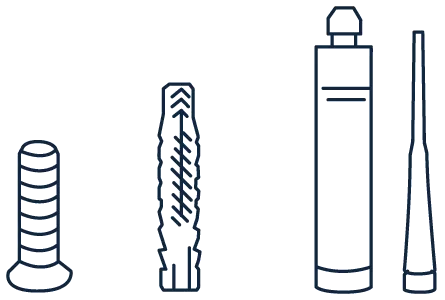

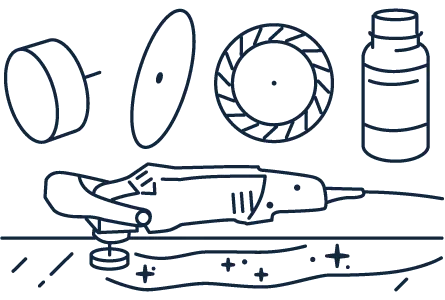

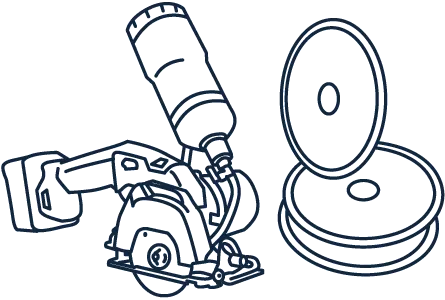

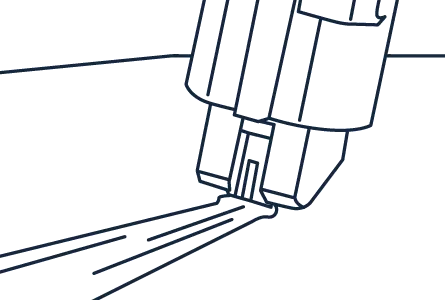

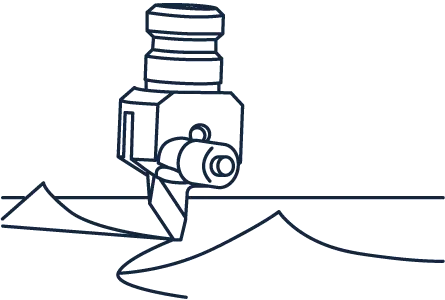

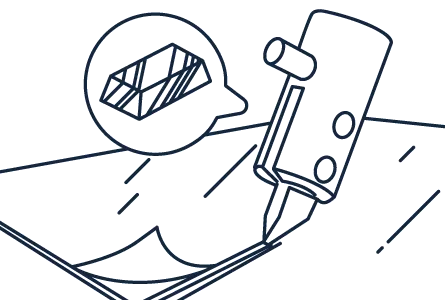

The diamond hollow drill with an external thread (Continental) R ½ inch is made of steel covered with protective lacquer and a diamond coating of sintered material.

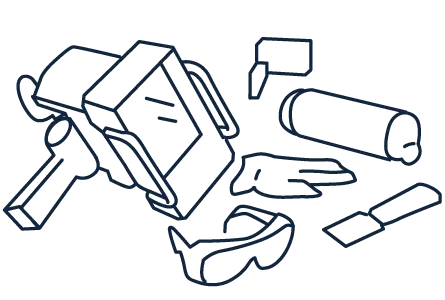

Application note:

Your Advantages

For normal use

Made in Italy

Technical details

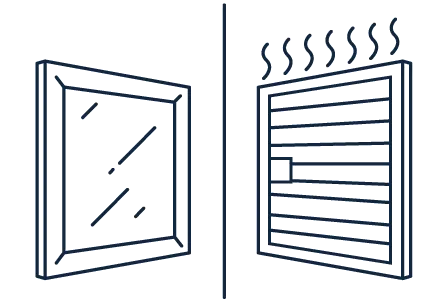

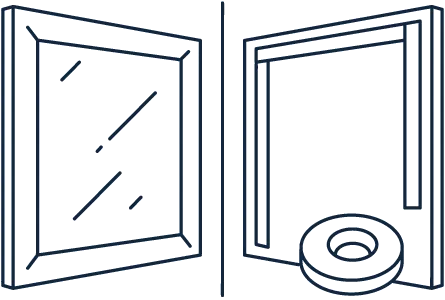

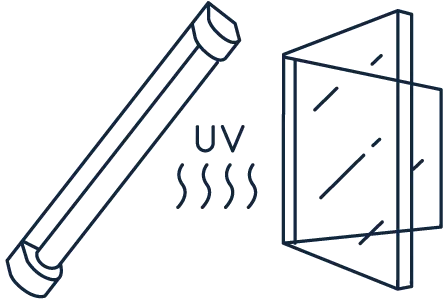

Application area

Glass , Indoor , Wet

Revolution

4,000 - 5,000 U/min

product

2ccd5001c8c61a79b0c00004ac1deadf

Standard diamond hollow drill

https://www.bohle.com/at-EN/Standard-diamond-hollow-drill/BO5000403

https://media.bohle.com/media/72/55/af/1772529043/BO5000403-PF1-A.png?ts=1772529043

InStock

1199998.8

EUR

BO5000403

2ccd5001c8c61a79b0c00004ac1deadf

75 mm

3 mm

Standard quality

1 Piece

Wet, Indoor, Glass

4,000 - 5,000 U/min

½ "

200

{"extensions":[],"displayParent":false,"mainVariantId":null,"configuratorGroupConfig":[{"id":"1ef30ca250effb664558d440b996150c","expressionForListings":true},{"id":"c2de7482ccece302f44c2d39e426fac1","expressionForListings":true},{"id":"3a34789669c877da523ef571ba8efa76","expressionForListings":true}],"displayCheapestVariant":null,"displayMainVariant":null}

true

true

Drill, diamond, hollow drill, steel, Continental, BO 5000403, BO5000403, 5000403

2ccd5001c8c61a79b0c00004ac1deadf

Standard diamond hollow drill

1199998.8

1199998.8

https://www.bohle.com/at-EN/Standard-diamond-hollow-drill/BO5000403

https://media.bohle.com/media/72/55/af/1772529043/BO5000403-PF1-A.png?ts=1772529043

InStock

BO5000403

2ccd5001c8c61a79b0c00004ac1deadf

75 mm

3 mm

Standard quality

1 Piece

Wet, Indoor, Glass

4,000 - 5,000 U/min

½ "

200

{"extensions":[],"displayParent":false,"mainVariantId":null,"configuratorGroupConfig":[{"id":"1ef30ca250effb664558d440b996150c","expressionForListings":true},{"id":"c2de7482ccece302f44c2d39e426fac1","expressionForListings":true},{"id":"3a34789669c877da523ef571ba8efa76","expressionForListings":true}],"displayCheapestVariant":null,"displayMainVariant":null}

true

true

Drill, diamond, hollow drill, steel, Continental, BO 5000403, BO5000403, 5000403

/Home ES

/BX

/BX/Home

/IT

/SE

/INT

/ZA

/IT/Home

/SE/Home

/INT/Home

/ZA/Home

/BALTIC

/BALTIC/Home BALTIC

/FR

/FR/Home

/FR/Home/Online Shop

/FR/Home/Online Shop/Workshop supplies

/Home ES/Online Shop

/Home ES/Online Shop/Workshop supplies

/Home ES/Online Shop/Workshop supplies/Glass processing

/IT/Home/Online shop

/IT/Home/Online shop/Workshop supplies

/IT/Home/Online shop/Workshop supplies/Glass processing

/UK

/UK/Home

/UK/Home/Online Shop

/UK/Home/Online Shop/Workshop supplies

/UK/Home/Online Shop/Workshop supplies/Glass processing

/UK/Home/Online Shop/Workshop supplies/Glass processing/Drilling

/UK/Home/Online Shop/Workshop supplies/Glass processing/Drilling/Hollow drill

/FR/Home/Online Shop/Workshop supplies/Glass processing

/FR/Home/Online Shop/Workshop supplies/Glass processing/Drilling

/Home ES/Online Shop/Workshop supplies/Glass processing/Drilling

/BALTIC/Home BALTIC/Online shop

/BALTIC/Home BALTIC/Online shop/Workshop supplies

/BALTIC/Home BALTIC/Online shop/Workshop supplies/Glass processing

/BALTIC/Home BALTIC/Online shop/Workshop supplies/Glass processing/Drilling

/AT

/AT/Home

/AT/Home/Online Shop

/AT/Home/Online Shop/Workshop supplies

/AT/Home/Online Shop/Workshop supplies/Glass processing

/AT/Home/Online Shop/Workshop supplies/Glass processing/Drilling

/ZA/Home/Online Shop

/ZA/Home/Online Shop/Workshop supplies

/SE/Home/Online Shop

/SE/Home/Online Shop/Workshop supplies

/SE/Home/Online Shop/Workshop supplies/Glass processing

/SE/Home/Online Shop/Workshop supplies/Glass processing/Drilling

/SE/Home/Online Shop/Workshop supplies/Glass processing/Drilling/Hollow drill

/DE

/DE/Home

/FR/Home/Online Shop/Workshop supplies/Glass processing/Drilling/Hollow drill

/Home ES/Online Shop/Workshop supplies/Glass processing/Drilling/Hollow drill

/ZA/Home/Online Shop/Workshop supplies/Glass processing

/ZA/Home/Online Shop/Workshop supplies/Glass processing/Drilling

/ZA/Home/Online Shop/Workshop supplies/Glass processing/Drilling/Hollow drill

/BALTIC/Home BALTIC/Online shop/Workshop supplies/Glass processing/Drilling/Hollow drill

/INT/Home/Online Shop

/DE/Home/Online shop

/DE/Home/Online shop/Workshop supplies

/DE/Home/Online shop/Workshop supplies/Glass processing

/INT/Home/Online Shop/Workshop supplies

/INT/Home/Online Shop/Workshop supplies/Glass processing

/INT/Home/Online Shop/Workshop supplies/Glass processing/Drilling

/BX/Home/Online Shop

/BX/Home/Online Shop/Workshop supplies

/BX/Home/Online Shop/Workshop supplies/Glass processing

/BX/Home/Online Shop/Workshop supplies/Glass processing/Drilling

/BX/Home/Online Shop/Workshop supplies/Glass processing/Drilling/Hollow drill

/DE/Home/Online shop/Workshop supplies/Glass processing/Drilling

/DE/Home/Online shop/Workshop supplies/Glass processing/Drilling/Hollow drill

/AT/Home/Online Shop/Workshop supplies/Glass processing/Drilling/Hollow drill

/INT/Home/Online Shop/Workshop supplies/Glass processing/Drilling/Hollow drill

/IT/Home/Online shop/Workshop supplies/Glass processing/Drilling

/IT/Home/Online shop/Workshop supplies/Glass processing/Drilling/Hollow drill

/online-shop/workshop-supplies/glass-processing/drilling

/online-shop

/online-shop/workshop-supplies/glass-processing

/online-shop/workshop-supplies/glass-processing/drilling/hollow-drill

/online-shop/workshop-supplies

018e50bac1ed76ce8bf0c35226592d1a

018e50bb1be67859a929e4c5bc3bd689

0190104bbd4f745488cc81926fe14e21

0190104beb4675689b34351165d1709c

01905d74ec5a7cb9a22a62ad6f7b346a

01905d75002671d3bde490622370a83e

01905d750f927774ac389f1bc7ee592a

01905d751c8b7dbe89d67acbd6d21c14

01905d75470f7ca79285ebdc8a214610

01905d7584b57966a59712fdee1a88d7

01905d75b719778da8830895a707808c

01905d75e59570bfad9e7d3133e4c310

019730a561167ea5923a0fadfc39690d

019730c8e5507da2ad3d80d085ea1c04

0476d97ed004409a96012006d7fd7cb0

083441515a1e4755a0b71555314c3659

09c13e3c67974258a0867b63a4750899

1560e2e901044847a6a0b9442c6e7126

19b829eb01f14f9d8ee96b1f352d1ae8

1a29f64f43124deea24f6710962d8484

1f6432a811644e9b90dfb2a503d85374

24b302f306d0499eb01c97fb88a312c0

2be884f1449b4d1792a181f47eed1256

308b720c8bc526461b7827ba68bcea10

34277a09ad51470eb88aa0c545530670

36f7d6e065534f95a4eadf83142ff82c

3a6a4d9907c94fa7beb7e610c0bd4cda

3f25fae1750f4704a3468d3f88ad0c99

404e495c53614121a2c4966e71c11f8a

4fa20b73610b4176a15745b0175e5d4a

59841e068f904e0a93ff3faedcf985e1

5aa7627b91154164a24cddbca7fc87a5

5bd93ee3d33f4a3db1047e7036addb61

60bd5a29c97c41dbaf8ea6c0e6ea25c3

622e5d9ab32b4366948b95caf4a66e97

65fcbec188134932bb7984fdd8829ca3

66082280ca5b4ad4b138a5a117284932

66fcf6e886eb46e489e6dd64f4244cb7

684b113e133a4ce6afdf0a557616c78e

6a8b89b3b53cd220f46bc57d7228bf1e

737cd764c4984152bad5d91d28a0df39

756ac1bea115494f8afb03e28ba27e10

762e1117bd8145bc8c9d7ff378b4ea95

77f6bab7a6a2482a942c27294a398efb

789540d56f0a4fc282cd9ba444bdf0ef

7d1aa740b93e42eca7818b0c3904fd6c

84d476e804804c8cb9887b787f3f5aa2

875fc2a9892c400d9d80f0d7e07c1345

8c7fcc85eb02ec9928b009cda355f693

97fa1fe428b0472e8415135381c04284

9bb3eeb52abe40d8a8c2af26fa0345ab

9e48ffa3bc35450bb62d7e0bf43a55e9

a041fc596ba9451a9bdc47a43910241f

a364d4e0391d49e7b86fa648be64bde1

a58adce92dc50f5e3456d80d75ad6dbf

a89b71fbd79f4014b23f1e3062b788da

ade472419a67ac0247a7dbd8e4394f99

afe88f453a38424a83e379e3e7875129

b06129e9d6e84a19b029ce108720a502

b501a08b9242afd7d26a76ecbbf24db7

b7e56567dfbb47bfb4fddf0a879f86d1

b7ef9f82c5e8fc79a3a868b509ba7d14

c359f037e5bc4f9dabaaa84c2ad08ff0

c38f097383d3471aa86eacf4dde1de93

c6d5352e5e49482eb04554d8e7e45a9b

ce3353c8c4c342aaed8fce29ef53c252

d1fb7f667c5054fad3f49d4ce6254908

d63b3c35bf254f98a21f8d11d2b15b21

d6542ab0ce7b4603b0dd90182e9408c2

e0290ed5289a4e338d768c73099643aa

e1151f2bd3594657a1c4dc5f2d8681e5

e3e4193ccb0d4adbb52653fe1d16a298

e3fd4773950d4606a308e2c6d4747cfd

eb8f01facb954e17b1850c0f3558152c

ecb7f08902af3c6e22345e8efba2898e

f04067f8262e41e890f040fe81565bf7

fef50ad352314fada9d7e5fae0adb8e4

018e50bac1ed76ce8bf0c35226592d1a

0190104bbd4f745488cc81926fe14e21

01905d74ec5a7cb9a22a62ad6f7b346a

01905d75002671d3bde490622370a83e

01905d750f927774ac389f1bc7ee592a

01905d751c8b7dbe89d67acbd6d21c14

019730a561167ea5923a0fadfc39690d

1560e2e901044847a6a0b9442c6e7126

789540d56f0a4fc282cd9ba444bdf0ef

36f7d6e065534f95a4eadf83142ff82c

018e50bb1be67859a929e4c5bc3bd689

f04067f8262e41e890f040fe81565bf7

7d1aa740b93e42eca7818b0c3904fd6c

01905d75470f7ca79285ebdc8a214610

404e495c53614121a2c4966e71c11f8a

622e5d9ab32b4366948b95caf4a66e97

9e48ffa3bc35450bb62d7e0bf43a55e9

737cd764c4984152bad5d91d28a0df39

19b829eb01f14f9d8ee96b1f352d1ae8

59841e068f904e0a93ff3faedcf985e1

e1151f2bd3594657a1c4dc5f2d8681e5

3f25fae1750f4704a3468d3f88ad0c99

0476d97ed004409a96012006d7fd7cb0

b06129e9d6e84a19b029ce108720a502

083441515a1e4755a0b71555314c3659

019730c8e5507da2ad3d80d085ea1c04

c38f097383d3471aa86eacf4dde1de93

a041fc596ba9451a9bdc47a43910241f

d63b3c35bf254f98a21f8d11d2b15b21

756ac1bea115494f8afb03e28ba27e10

34277a09ad51470eb88aa0c545530670

a58adce92dc50f5e3456d80d75ad6dbf

ecb7f08902af3c6e22345e8efba2898e

ade472419a67ac0247a7dbd8e4394f99

01905d75e59570bfad9e7d3133e4c310

684b113e133a4ce6afdf0a557616c78e

01905d7584b57966a59712fdee1a88d7

fef50ad352314fada9d7e5fae0adb8e4

a364d4e0391d49e7b86fa648be64bde1

d6542ab0ce7b4603b0dd90182e9408c2

875fc2a9892c400d9d80f0d7e07c1345

a89b71fbd79f4014b23f1e3062b788da

1f6432a811644e9b90dfb2a503d85374

24b302f306d0499eb01c97fb88a312c0

3a6a4d9907c94fa7beb7e610c0bd4cda

84d476e804804c8cb9887b787f3f5aa2

b7e56567dfbb47bfb4fddf0a879f86d1

2be884f1449b4d1792a181f47eed1256

01905d75b719778da8830895a707808c

5aa7627b91154164a24cddbca7fc87a5

ce3353c8c4c342aaed8fce29ef53c252

8c7fcc85eb02ec9928b009cda355f693

66fcf6e886eb46e489e6dd64f4244cb7

c359f037e5bc4f9dabaaa84c2ad08ff0

77f6bab7a6a2482a942c27294a398efb

0190104beb4675689b34351165d1709c

97fa1fe428b0472e8415135381c04284

c6d5352e5e49482eb04554d8e7e45a9b

9bb3eeb52abe40d8a8c2af26fa0345ab

e3fd4773950d4606a308e2c6d4747cfd

6a8b89b3b53cd220f46bc57d7228bf1e

b7ef9f82c5e8fc79a3a868b509ba7d14

308b720c8bc526461b7827ba68bcea10

762e1117bd8145bc8c9d7ff378b4ea95

09c13e3c67974258a0867b63a4750899

e3e4193ccb0d4adbb52653fe1d16a298

The diamond hollow drill with an external thread (Continental) R ½ inch is made of steel covered with protective lacquer and a diamond coating of sintered material.

1199998.8